A device and method for membrane distillation

A technology of membrane distillation and water vapor, applied in total evaporation, heating water/sewage treatment, energy wastewater treatment, etc., can solve the problems of improving water permeation flux in membrane distillation, achieve low equipment cost, improve efficiency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

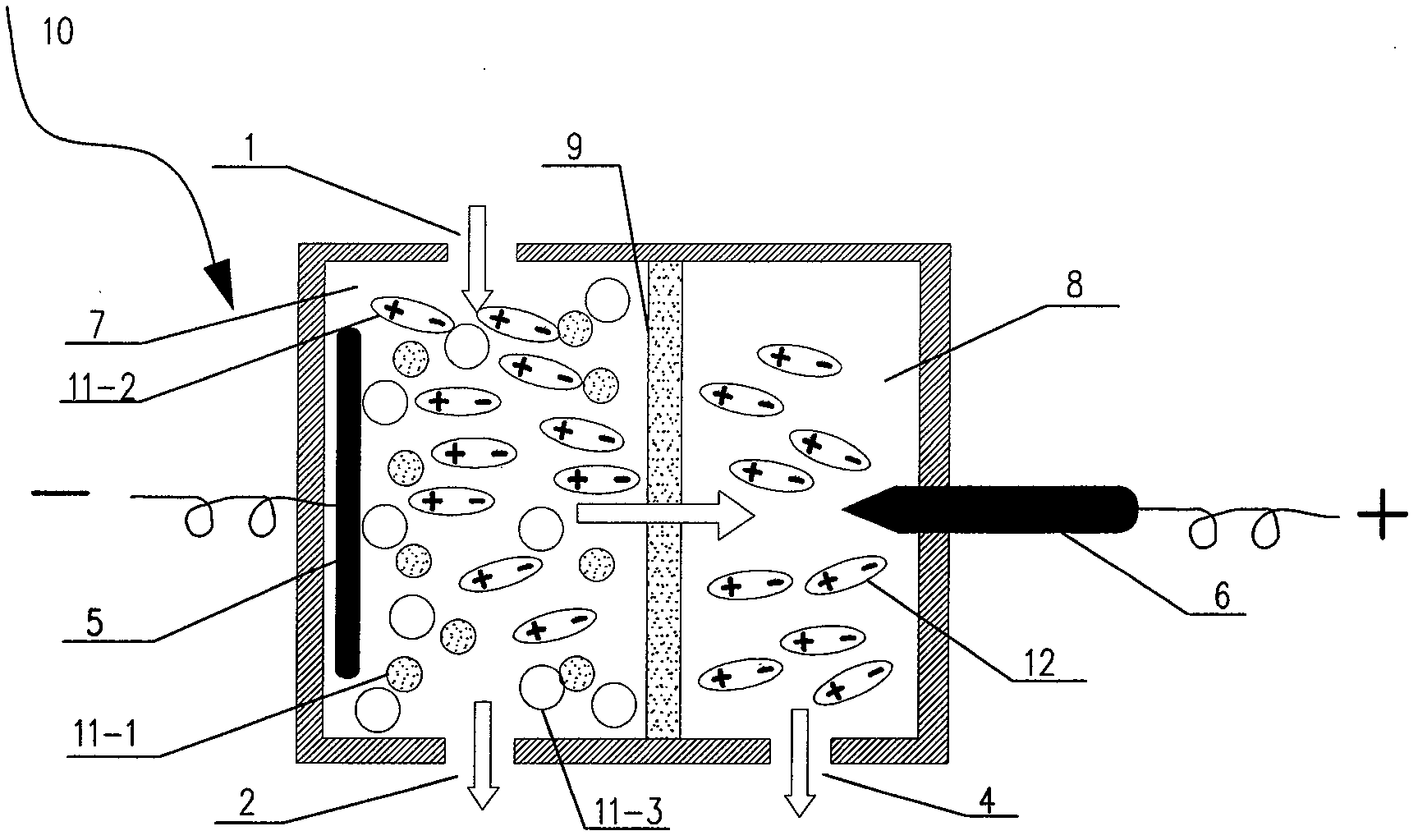

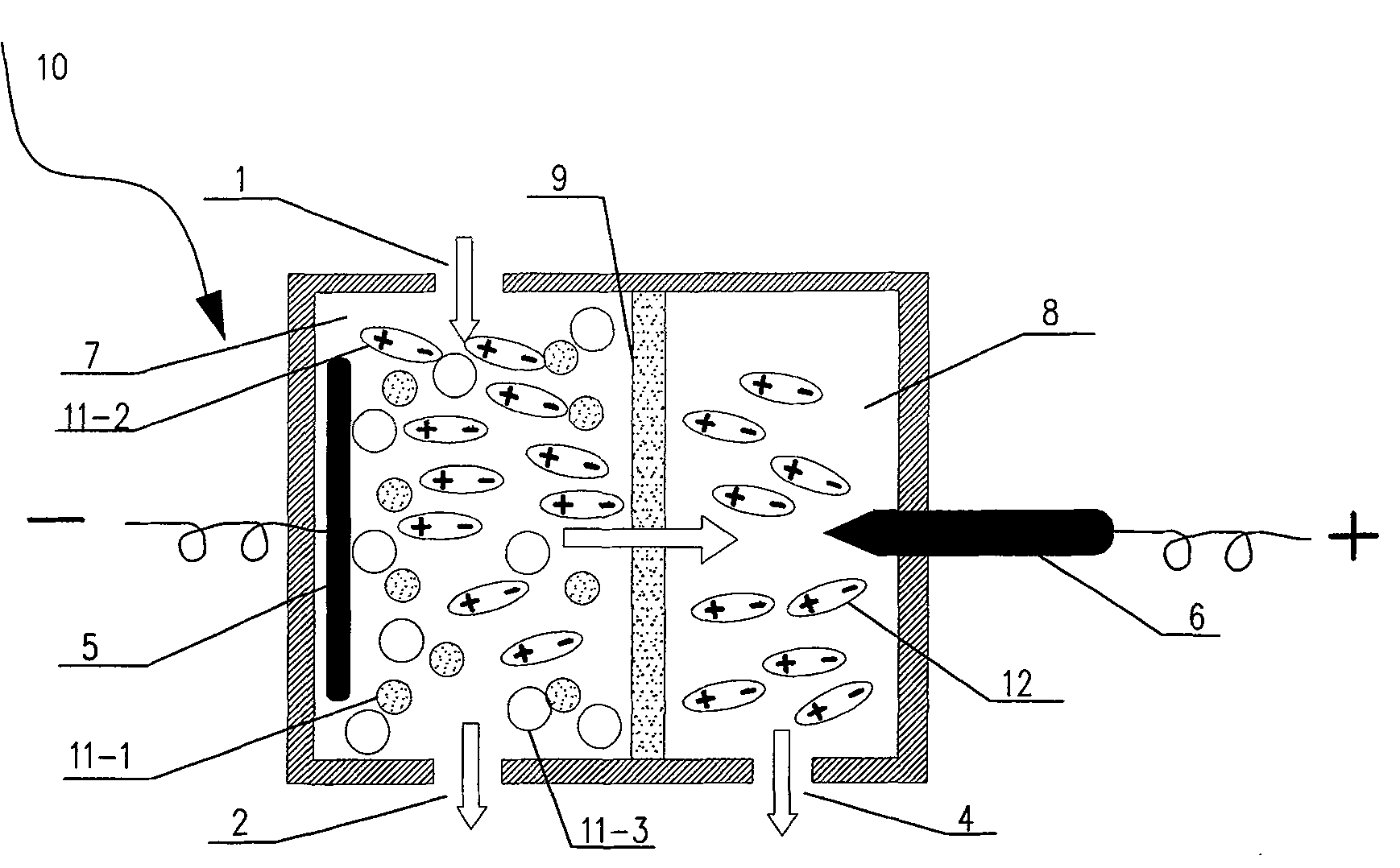

[0024] Such as figure 1 As shown, an exemplary asymmetric electrostatic field coupled membrane distillation device 10 includes a raw material chamber 7 , a permeation chamber 8 , and a flat membrane 9 . In one embodiment, the feed chamber 7 contains an inlet 1 and an outlet 2 for the aqueous solution. The aqueous solution is NaCl aqueous solution, the water molecules in the aqueous solution are 11-2, Na + Ion 11-1 and Cl - Ion 11-3, the NaCl content is 8wt%, the raw material flow rate is 0.6L / min, the raw material side temperature is 50°C, and the raw material side is normal pressure. In the raw material chamber 7, there is a plate electrode 5, which is a cathode; in the transmission chamber 8, a needle-shaped electrode 6, which is an anode. Apply a DC voltage of 2000 volts on the plate electrode 5 and the needle electrode 6 . The pressure in the permeation chamber 8 is 1 kPa.

[0025] The NaCl aqueous solution enters the raw material chamber 7 from the inlet 1, and conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com