Preparation method of low-VOC (volatile organic compound) antimicrobial glass-fiber-reinforced polypropylene (PP) composite material

A composite material, polypropylene technology, applied in the field of preparation of low-VOC, antibacterial glass fiber reinforced polypropylene composite materials, can solve the problems of VOC substances, discount of adsorption and degradation ability, easy aggregation of nano-inorganic powder, etc., to achieve Excellent antibacterial effect, reduced density, and less abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

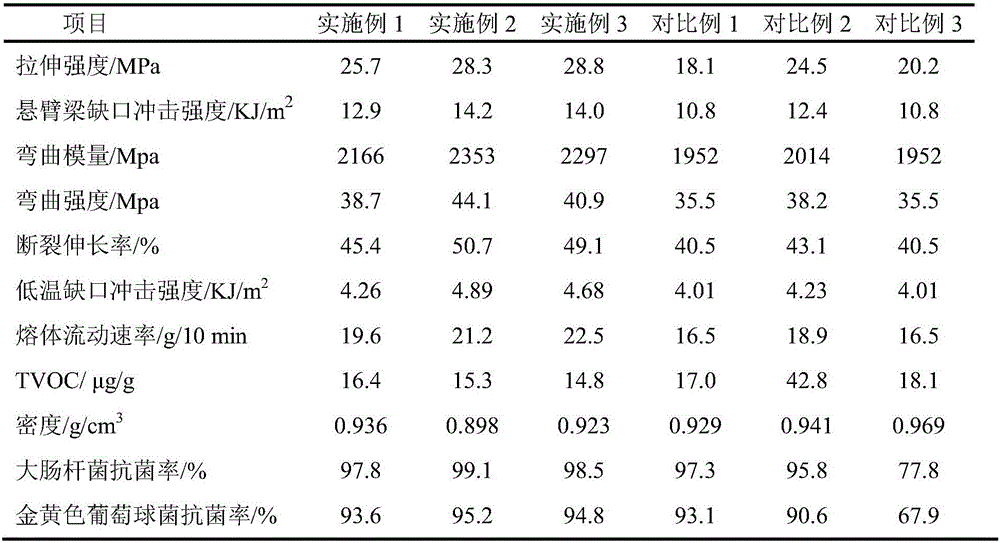

Examples

Embodiment 1

[0028] First prepare glass fiber reinforced polypropylene masterbatch, weigh dry polypropylene 4000g, long glass fiber 5100g, mica powder 420g, antioxidant 1010 60g, anti-ultraviolet additive CYASORB UV-V680 60g, silver-loaded carbon microsphere antibacterial agent 160g After mixing evenly, add a twin-screw extruder to melt and blend at 195°C, extrude through the extruder, cool and pelletize to obtain glass fiber reinforced polypropylene masterbatch;

[0029] Next, prepare hollow glass microsphere master batches, weigh and mix 720g of dried hollow glass microspheres and 330g of VOC inhibitors evenly, then add them to a twin-screw extruder for melting and blending at 195°C, extrude, cool and pelletize to obtain hollow glass Microbead masterbatch, wherein the mass of the 720g hollow glass microsphere surface compatibilizer PP-g-MAH accounts for 320g, and the VOC inhibitor is composed of nano Composed of photocatalyst, attapulgite, sepiolite and diatomite;

[0030]Composite mate...

Embodiment 2

[0032] First prepare glass fiber reinforced polypropylene masterbatch, weigh dry polypropylene 6500g, long glass fiber 2300g, antioxidant 1010 20g, anti-ultraviolet additive CYASORB UV-V680 40g, silver-loaded carbon microsphere antibacterial agent 200g and mix evenly, Add the twin-screw extruder to melt and blend at 210°C, extrude through the extruder, cool and pelletize to obtain glass fiber reinforced polypropylene masterbatch;

[0033] Next, prepare hollow glass microsphere master batches, weigh and mix 650g of dried hollow glass microspheres and 230g of VOC inhibitors evenly, then add them to a twin-screw extruder for melting and blending at 195°C, extrude, cool and pelletize to obtain hollow glass Microbead masterbatch, wherein the quality of the 650g hollow glass microsphere surface compatibilizer PP-g-MAH accounts for 170g, and the VOC inhibitor is composed of nano Composed of photocatalyst, attapulgite, sepiolite and diatomite;

[0034] Composite material preparation,...

Embodiment 3

[0036] First prepare glass fiber reinforced polypropylene masterbatch, weigh dry polypropylene 6700g, long glass fiber 3400g, mica powder 200g, antioxidant 1010 40g, anti-ultraviolet additive CYASORB UV-V680 30g, silver-loaded carbon nanotube antibacterial agent 290g After mixing evenly, add the twin-screw extruder to melt and blend at 210°C, extrude through the extruder, cool and pelletize to obtain glass fiber reinforced polypropylene masterbatch;

[0037] Next, prepare hollow glass microsphere master batches, weigh and mix 1050g of dried hollow glass microspheres and 320g of VOC inhibitors evenly, then add them to a twin-screw extruder for melt blending at 195°C, extrude, cool and pelletize to obtain hollow glass Microbead masterbatch, wherein the quality of the 1050g hollow glass microsphere surface compatibilizer PP-g-MAH accounts for 320g, and the VOC inhibitor is composed of nano Composed of photocatalyst, attapulgite, sepiolite and diatomite;

[0038] Composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com