Hot-press forming process of counterweight filler with high specific gravity

A technology of hot pressing and counterweighting, which is applied in metal processing equipment, transportation and packaging, etc. It can solve the problems of uneven density of heavy blocks, low quality of finished products, and slow processing speed, so as to achieve fast production speed and high output. Fast speed and guaranteed quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enhance the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

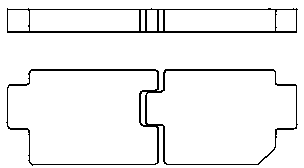

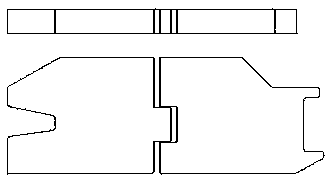

[0025] 1. If Figure 1-27 As shown, the present invention is a high-specific-gravity counterweight hot-press forming process, comprising the following steps: (1) material selection: selecting waste metal materials such as scrap iron and scrap steel;

[0026] (2) Broken material: transport the selected raw materials to the metal crusher 1 for crushing;

[0027] (3) Put it into the intermediate silo 3; at the lower end of the discharge port of the metal crusher 1, a belt conveyor 2 is provided to transport the broken material to the intermediate silo 3, and the belt conveyor 2 transfers the crushed material from the intermediate material The upper end of the bin mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com