Forming machine for fireproof heat insulating board of outer wall

A technology of fireproof heat preservation and board forming machine, which is applied in the field of construction machinery, can solve the problems of poor compactness, hollow bricks that fail to meet quality requirements, and fireproof heat preservation boards that fail to meet quality requirements, so as to facilitate construction and improve the effect of fireproof heat preservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

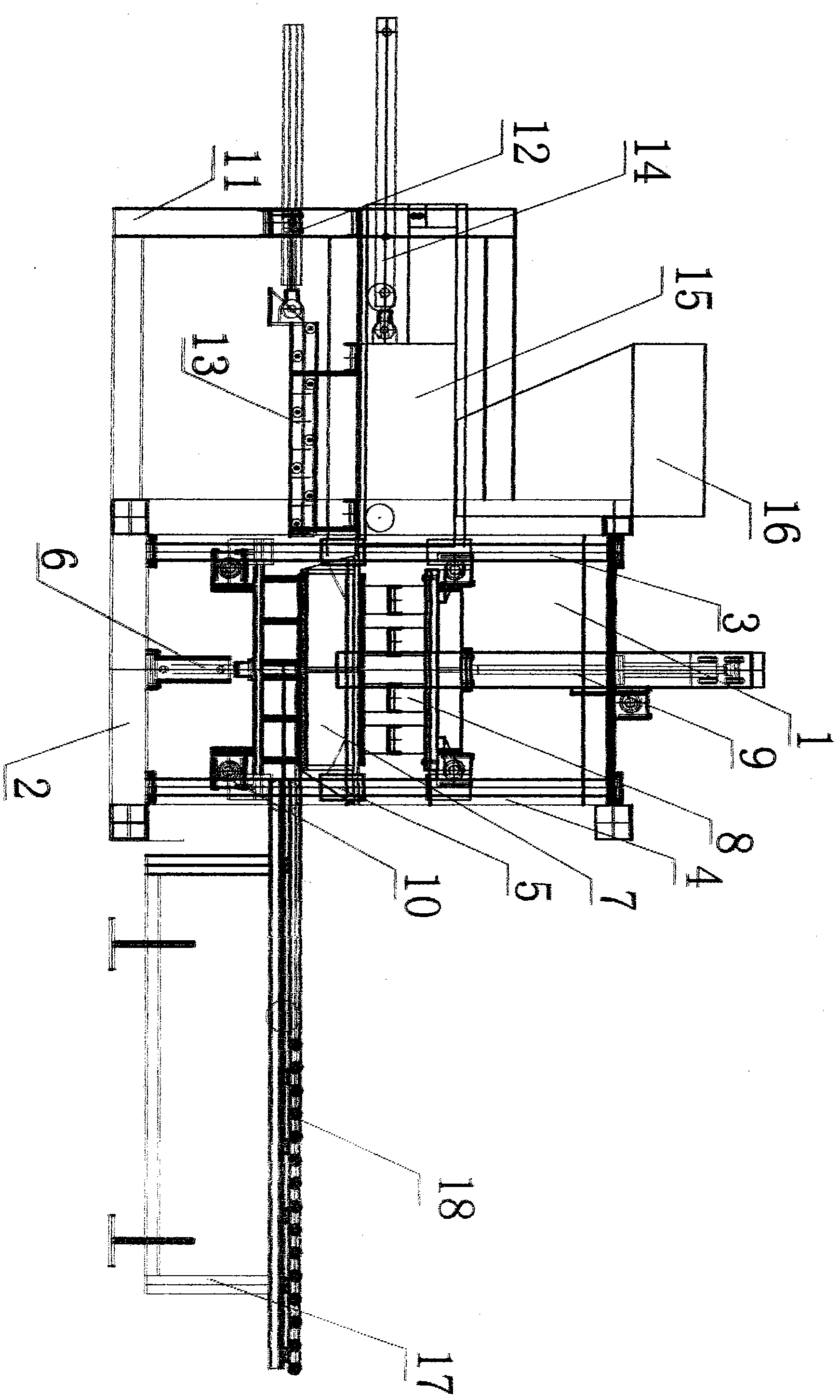

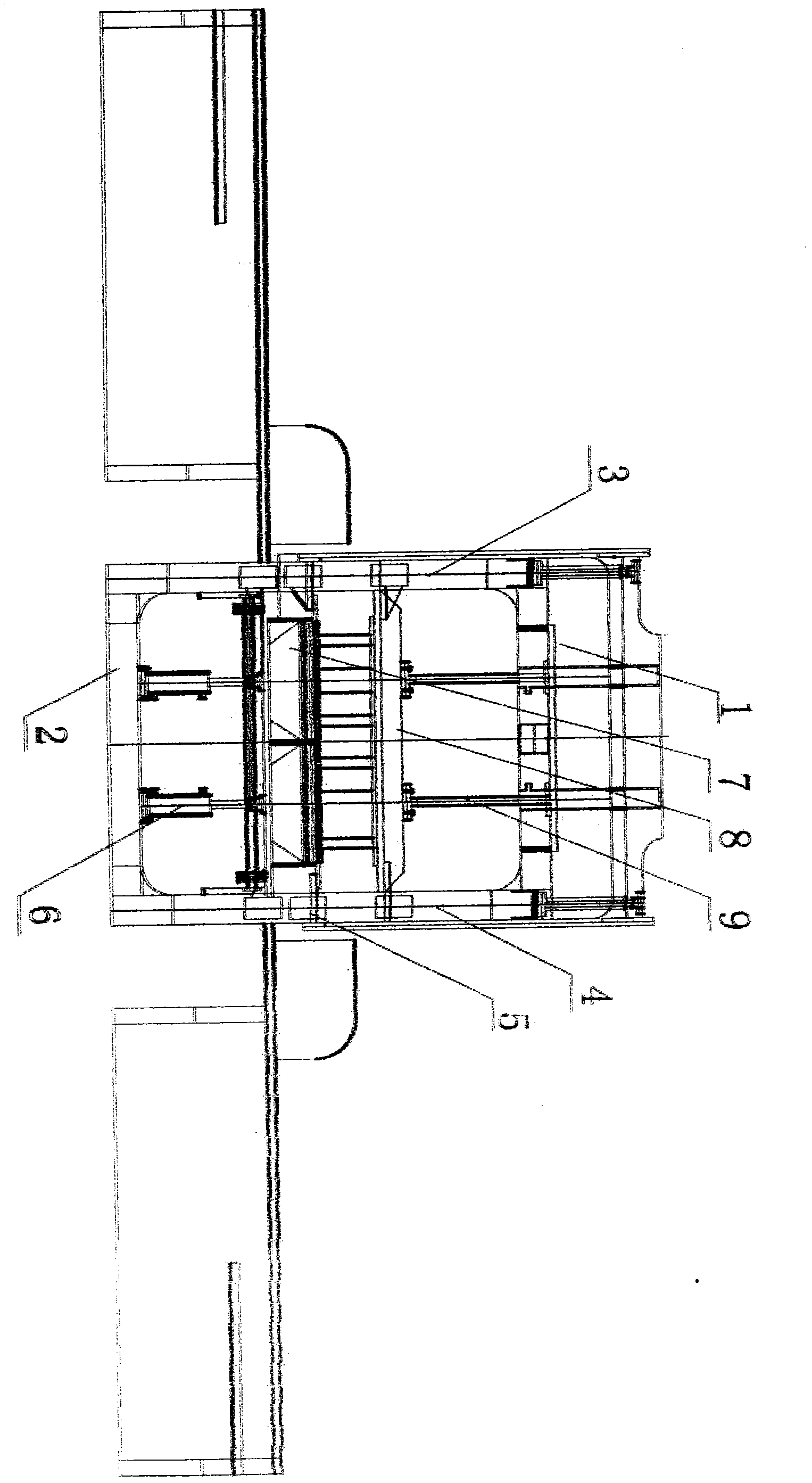

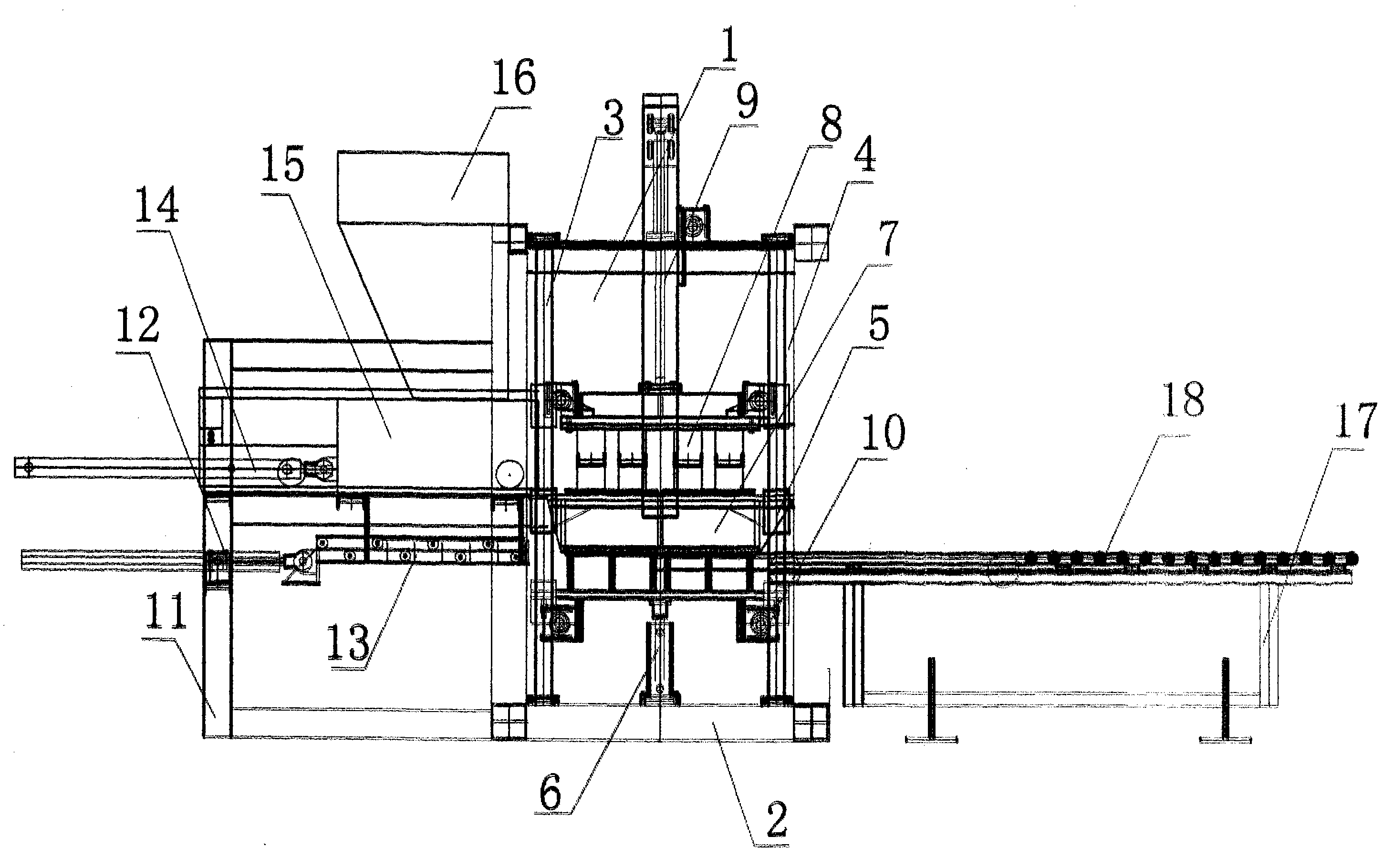

[0014] like figure 1 , figure 2 As shown, the molding machine for fire-proof and heat-insulating panels for external walls includes a molding mechanism, a push plate distribution mechanism, and a plate transfer mechanism. The four corners are provided with a column 3 composed of a guide column 4 and a guide sleeve 5, the guide column 4 can move up and down in the guide sleeve 5, and the base 2 is provided with two lower die head oil tops 6, the lower die head oil The upper part of the top 6 is the material storage mold box 7, and the upper part of the material storage mold box 7 is the upper die head 8. Column 4 links to each other, in order to be beneficial to the ups and downs of upper die head 8 is stable, and storage mold box 7 is also connected with guide post 4 by four synchronous racks 10, in order to be beneficial to the ups and downs of lower die head smoothly. The push pedal distribution mechanism includes a frame body 11, a push pedal oil top 12, a push trolley 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com