Large and bulky paper pulp die-pressing process and device

A molding equipment and pulp technology, applied in the direction of textiles and papermaking, etc., can solve the problems of not being able to work completely and effectively, only reaching 1.5mm, and not being able to obtain blanks, etc., to achieve the improvement of technical level, uniform thickness, and increase variety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

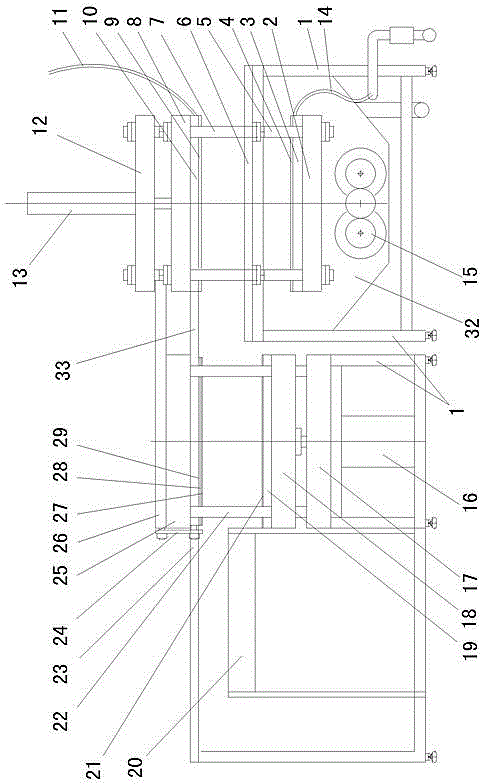

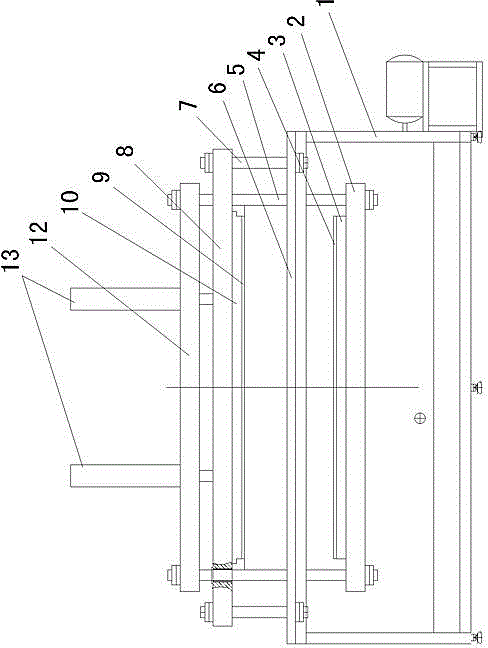

[0025] Large thick body pulp molding process step of the present invention is as follows:

[0026] ⑴. A pulp box with paper pulp is installed under the forming equipment, and a pulp stirring mechanism is installed under the inner side of the pulp box. immersed in pulp;

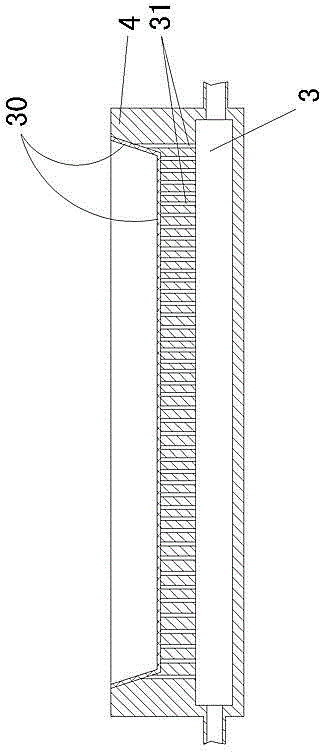

[0027] (2) Vacuumize the forming die by using a vacuum device to remove water, so that the pulp material is covered on the wire mesh on the inner surface of the forming die to form the required thickness;

[0028] ⑶. The forming die is moved upwards out of the pulp box driven by the driving mechanism, and after further dehydration, it is matched with the forming punch located above the pulp box, and then the forming die is released to vacuumize, and the vacuum valve of the forming punch is opened, so that The wet embryo formed in the mold is adsorbed to the forming punch;

[0029] ⑷. Translate the forming punch and the wet embryo transferred to the forming punch to the shaping equipment through the lateral m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com