Rapid ground tamping device for housing construction project

An engineering and ground technology, which is applied in the field of rapid ground tamping devices for housing construction, can solve problems such as uneven ground tamping density, hand joint damage, and uneven force on the ground, so as to reduce efficiency, reduce workload, and reduce work costs. relaxing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

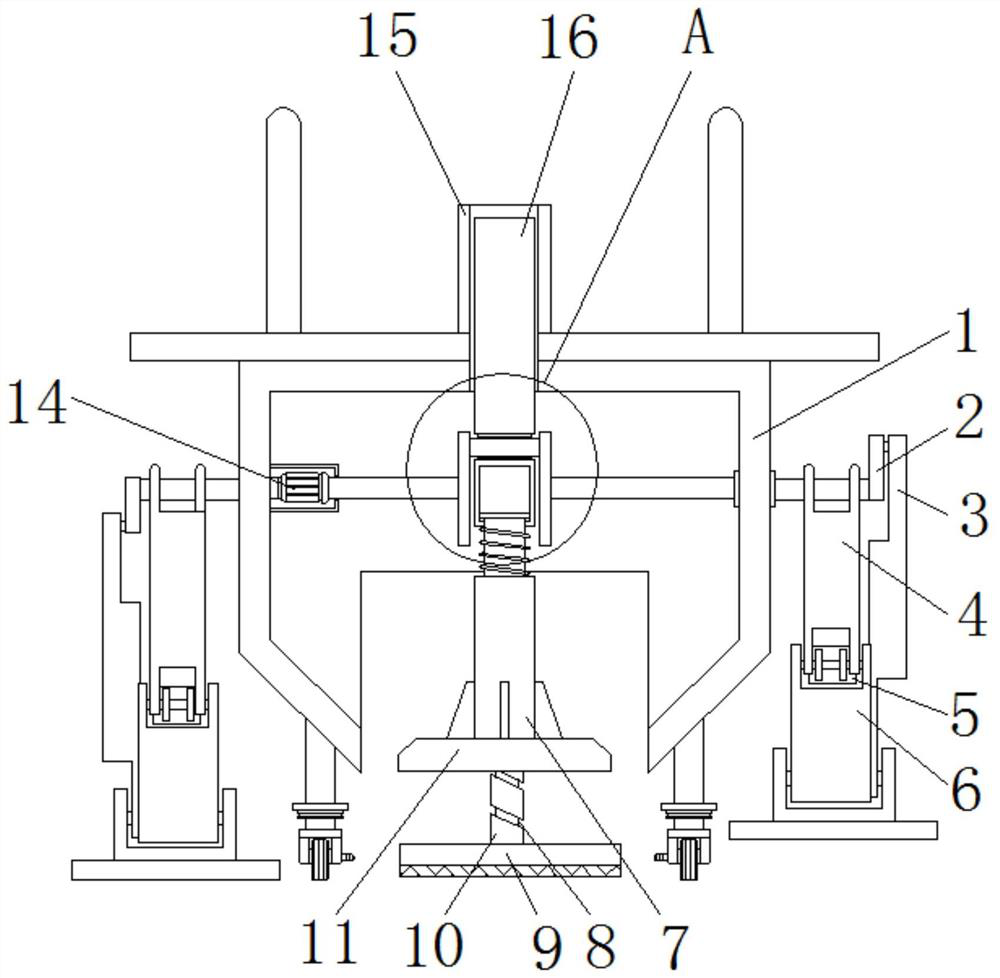

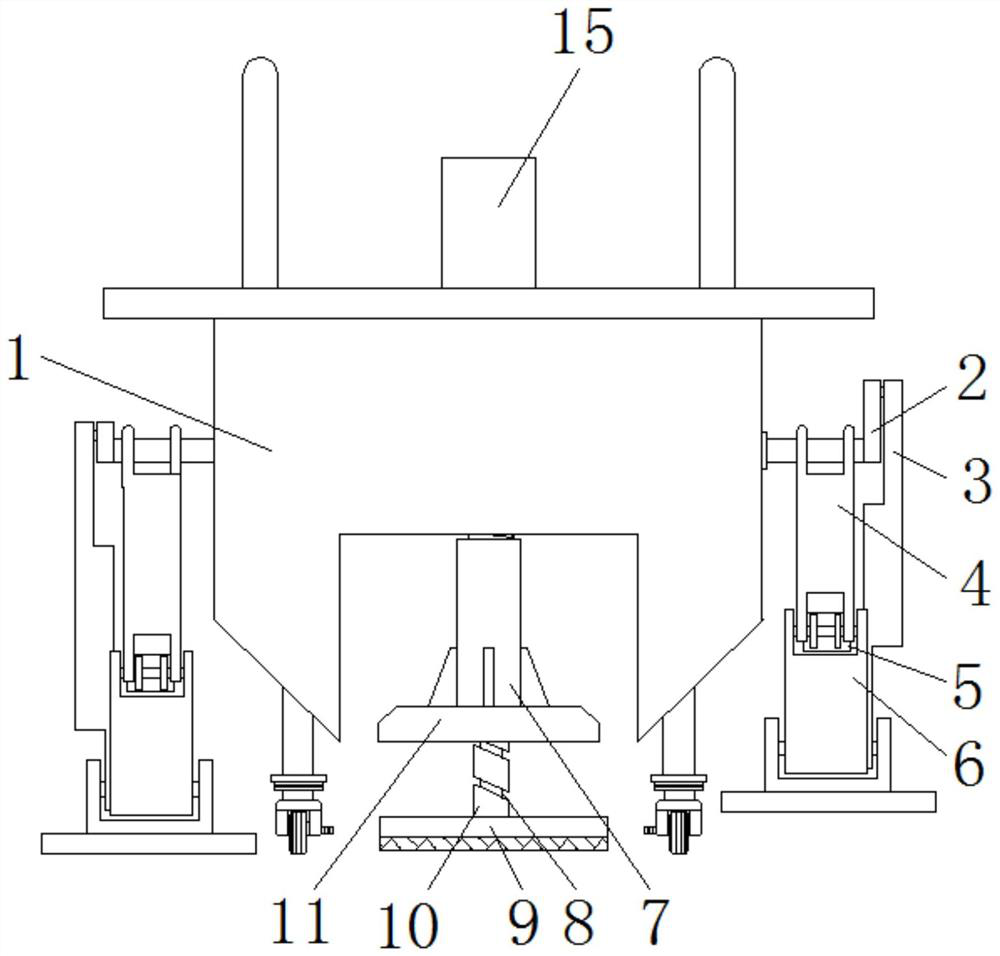

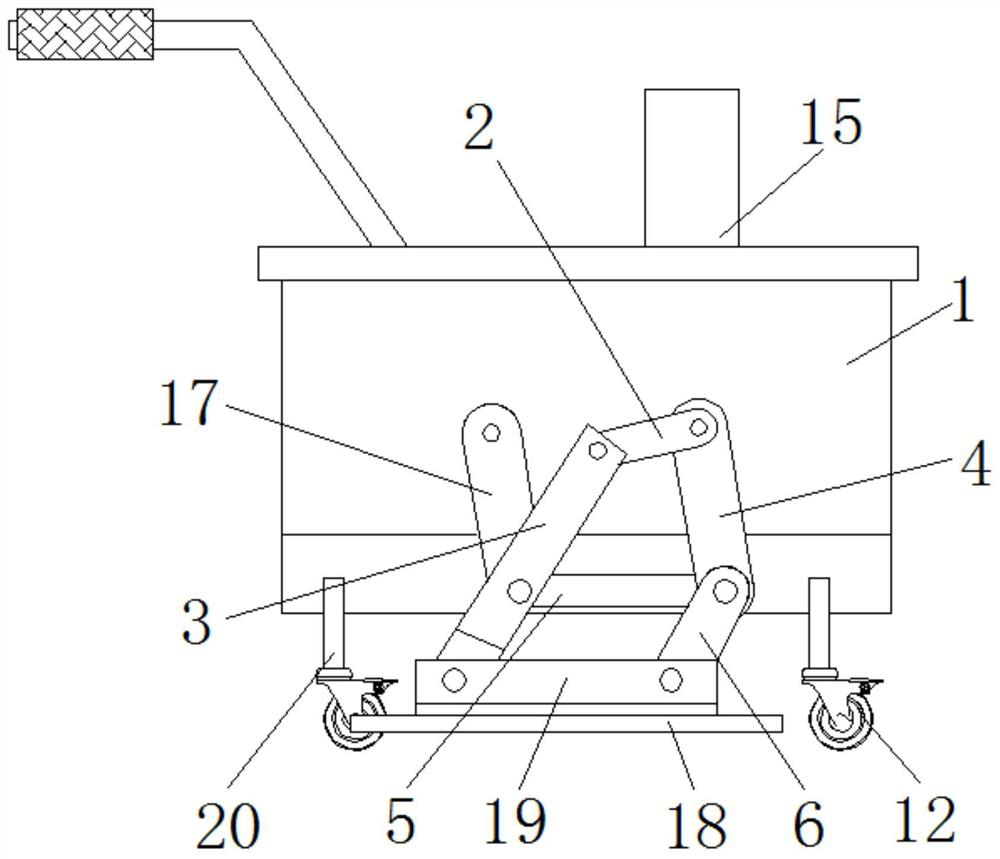

[0038] Example 1, such as figure 1 , 2 , 4, 5, 6, and 7, when the work is carried out for ground compaction work, first start the drive motor 14, and then drive the rotating rod 25 and the rotating disk 26 to rotate, and the rotating disk 26 drives the limit rod A21 to rotate along its arc, and then Under the action of the connection of the limit rod A21, the two groups of turntables 26 and the turn rod 25 are rotated together. When the limit rod A21 rotates along the arc of the turntable 26, it simultaneously moves along the inner side of the connecting frame 13. Move, and then drive the connecting frame 13, the connecting rod A16 and the casing 22 to reciprocate up and down, and then drive the sliding bar 23 and the connecting column 7 to reciprocate up and down, so that the connecting column 7 is compacted on the ground. When the connecting column 7 hits When it reaches the ground, the spring 24 is contracted by the impact force, so that the slide bar 23 shrinks a certain ...

Embodiment 2

[0039] Example 2, such as figure 1 , 2 , 4, 5, 6, and 7, when the connecting column 7 moves up and down, it drives the connecting frame 13 to move up and down, since the moving track of the connecting frame 13 is straight, when the connecting frame 13 slides inside the annular groove 8 , under the guidance of the annular groove 8, the installation rod A10 is forced to rotate, thereby driving the brush plate 9 to rotate, so that the brush plate 9 can clean up the ground after tamping, ensuring the flatness of the ground, so that workers do not need to carry out follow-up tidy.

[0040] Working principle: When the ground is being compacted, the driving motor 14 is first started, and then the rotating rod 25 and the turntable 26 are driven to rotate. Next, the two sets of turntables 26 and the rotating rods 25 are rotated together. When the limit rod A21 is rotating along the arc of the turntable 26, it moves along the inner side of the connecting frame 13, thereby driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com