Compression ratio adjustment method for prepressing spiral structure

A pre-pressing and spiral technology, applied in the field of pre-pressing spirals, can solve problems such as changes in internal parameters of welding deformed spirals, difficult operation of cutting spiral pre-pressing blades, complicated disassembly of a spiral, etc., to achieve difficult resolution, reasonable design, and improved production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

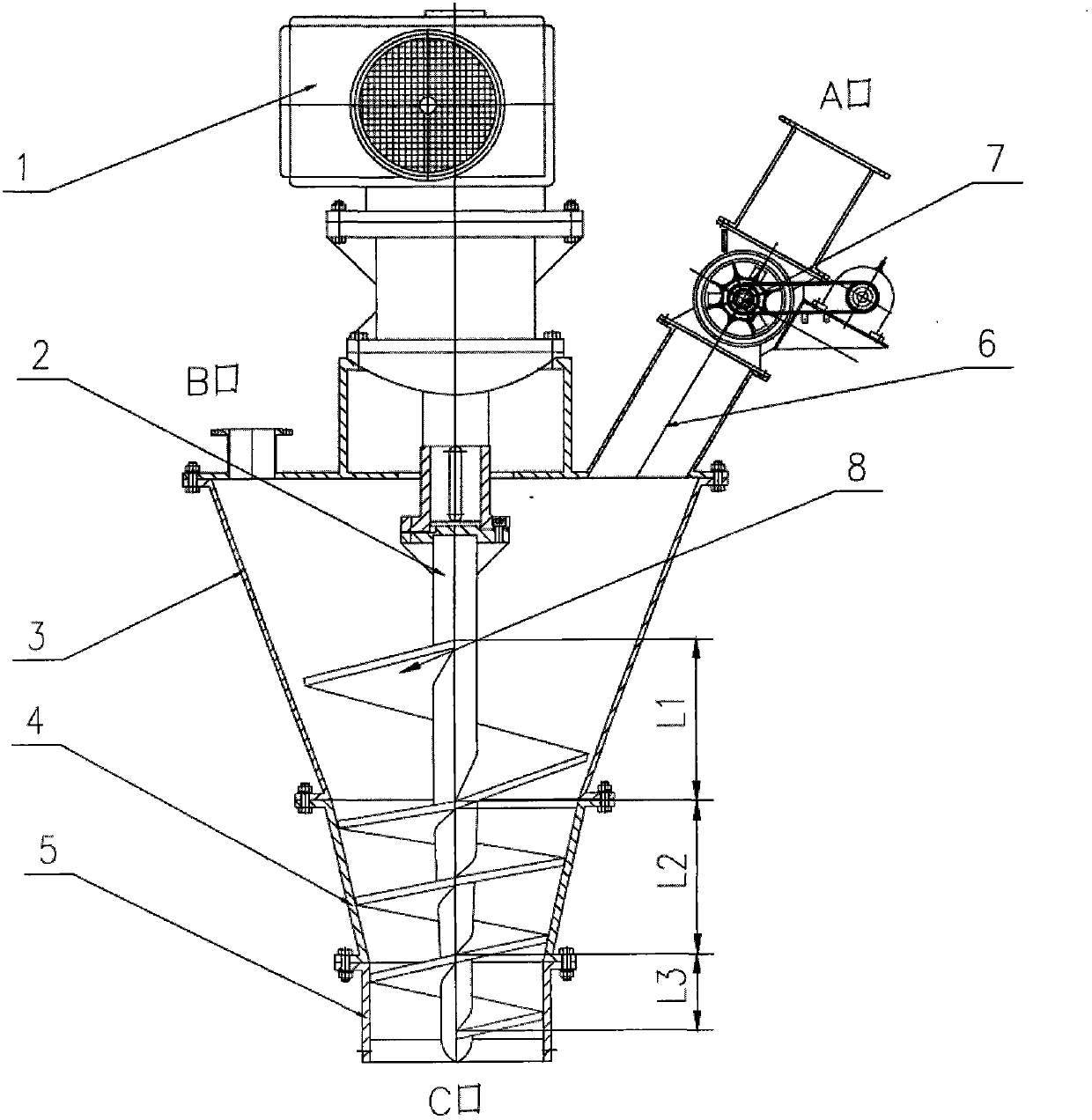

[0044] As shown in the figure; the pre-pressing silo 4 is set under the pre-pressing silo 3 of the spiral structure, the guide hopper 5 is set under the pre-pressing silo 4, the cover is set above the biting hopper 3, and the middle part of the cover is set The transmission support, the shaft hole is reserved in the center of the cover, the screw transmission system 1 is set above the transmission support, and the screw shaft 2 is set below the screw drive system 1; the screw shaft 2 is set in the shaft hole reserved in the center of the cover, and the outside of the screw shaft 2 Set the spiral blade 8, set the dust removal port B on one side above the cover of the bite bin 3, and set the feed pipe 6 on the other side above the cover of the bite bin 3; set the feed port A above the feed pipe 6, An adjustable feeding device 7 is arranged in the middle section of the feeding pipe 6 .

Embodiment 2

[0046] As shown in the figure; a large mouth is set above the bite bin 3, and a small mouth is set under the pre-press bin 4. The bite bin 3 and the pre-press bin 4 are set with a trumpet shape with a large top and a small bottom. The small opening of the warehouse 4 corresponds to the guide hopper 5; the bite hopper 3, the pre-pressing hopper 4, and the guide hopper 5 are provided with a screw blade 8 coaxial with the screw shaft 2, and the upper part of the screw blade 8 corresponds to the feed pipe 6 The biting spiral leaf segment L1 in the biting material bin 3 is provided with a large pitch, the pre-pressing spiral leaf segment L2 in the pre-pressing bin 4 is provided with a small pitch, and the upper end of the biting material spiral leaf segment L1 is connected to the lower end of the pre-pressing spiral leaf segment L2 The pitch of the helical blade 8 between the upper and lower gradient settings, the upper width of the helical blade 8 and the lower narrow setting; the ...

Embodiment 3

[0048] When working, the screw drive system 1 drives the screw blade 8 on the screw shaft 2 to rotate and convey the material, and the input amount of the material is synchronized with the processing amount of the next equipment; the material is input into the feed pipe 6 through the feed port A, and the feed pipe 6 The material is input into the bite bin 3 through the adjustable feeding device 7 in the middle section; the output volume of the adjustable feeding device 7 is adjusted according to the setting of the compression ratio; the setting of the compression ratio is: the compression ratio is 2.5 Adjust between -1.05:1, the compression of the material is through the pitch between the screw blades 8 from large to small and the change of the screw blade 8 from wide to narrow, and the screw blade 8 squeezes the material downward through rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com