Method for preparing organic-inorganic hybrid octafunctional epoxy POSS resin and method for preparing carbon fiber reinforced composite material

A reinforced composite material and hybrid eight-functional technology, which is applied in the field of POSS resin preparation, can solve problems such as poor performance, and achieve the effects of high yield, clear chemical composition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

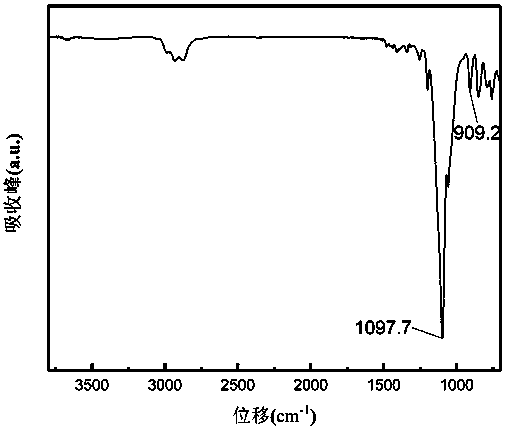

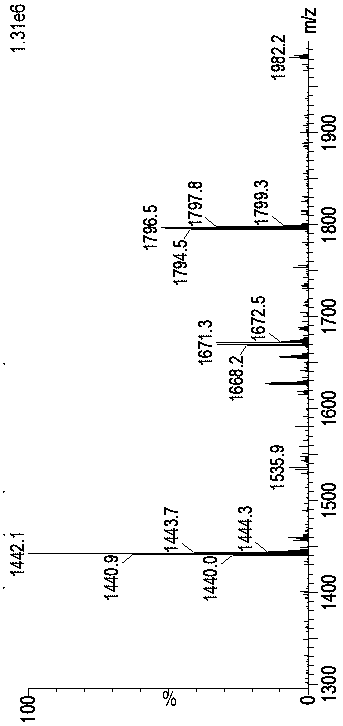

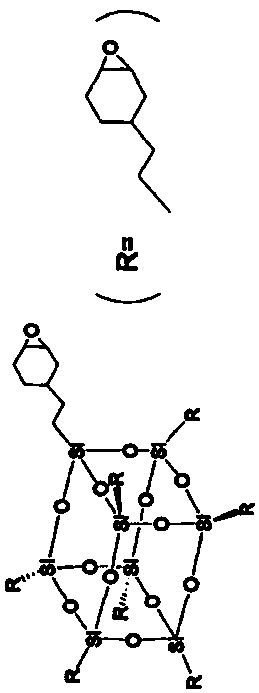

[0020] Embodiment 1: This embodiment records a preparation method of an organic-inorganic hybrid octafunctional epoxy POSS resin, and the method is specifically as follows:

[0021] At room temperature, add 10~1000mL of organic solvent, 3~15mL of 3~20% tetramethylammonium hydroxide aqueous solution and 5~100g of 2-(3, 4-epoxycyclohexyl) into a round-bottomed flask -Ethyltriethoxysilane or 2-(3,4 epoxycyclohexyl)-ethyltrimethoxysilane, stir and react at 20℃~90℃ for 6~200h; after the reaction, 70% of the The solvent was evaporated using a rotary evaporator to obtain a colorless and transparent liquid, namely an organic-inorganic hybrid octafunctional epoxy POSS resin, with a yield of 89.4%. The present invention utilizes 2-(3, 4 epoxycyclohexyl)-ethyltriethoxysilane or 2-(3,4 epoxycyclohexyl)-ethyltrimethoxysilane as monomer, and uses tetrahydrofuran and the like as solvent , an organic-inorganic hybrid octafunctional epoxy POSS resin with POSS as the core, 8 siloxane chains as...

specific Embodiment approach 2

[0022] Embodiment 2: The preparation method of an organic-inorganic hybrid octafunctional epoxy POSS resin described in Embodiment 1, wherein the organic solvent is toluene, xylene, ethylbenzene, acetone, butanone, tetrahydrofuran, One or more of methanol, ethanol and isopropanol. The polarity of the solvent has a great influence on the hydrolysis and condensation of siloxane. Hydrolysis of siloxane produces hydroxyl groups, and hydrogen bonds are formed between the hydroxyl groups to hinder the subsequent condensation reaction. Properly increasing the polarity of the solvent can weaken the hydrogen However, if the polarity of the solvent is too large, the solubility of the condensation intermediate in the solvent is poor, which is unfavorable for the continuation of the condensation. Therefore, the above solvent is selected because the cost is low and the yield is high.

specific Embodiment approach 3

[0023] Embodiment 3: A method for preparing a carbon fiber reinforced composite material by using the organic-inorganic hybrid octafunctional epoxy POSS resin prepared in Embodiment 1 or 2 as a matrix, and the method is as follows:

[0024] Mix organic-inorganic hybrid octafunctional epoxy POSS resin and epoxy resin curing agent at 30~120℃ and stir evenly to obtain a POSS-based epoxy resin composition. Put 20~60 loops of wrapped fibers in POSS Infiltrate the base epoxy resin composition for 3~60min, transfer it to the mold, start heating and curing, the heating rate is 10℃ / min, the pressure is 50~150Mpa at 140℃, and the curing temperature is 80~200℃. The three temperatures are used as the curing stage, and the curing time is 3-15h, that is, the carbon fiber reinforced composite material is obtained.

[0025] Specific embodiment four: a kind of method for preparing carbon fiber reinforced composite material described in specific embodiment three, the mass ratio of described org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com