Method for activating calcium magnesium phosphate fertilizer by virtue of low-molecular organic acid

A technology of low-molecular organic acid and calcium-magnesium phosphate fertilizer, applied in liquid fertilizers, fertilization devices, fertilizer mixtures, etc., can solve problems such as unclear environmental risks and application restrictions, and achieve simple preparation methods, convenient operation, and improved phosphorus use rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

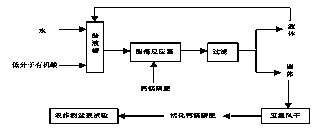

Method used

Image

Examples

Embodiment 1

[0028] First prepare the citric acid solution of 15mmol / L, place it in the liquid storage tank, then add the citric acid solution in the liquid storage tank to the shaking reactor with calcium magnesium phosphate fertilizer, the liquid-solid mixture of citric acid solution and calcium magnesium phosphate fertilizer The ratio is 15ml: 1g, wherein the main chemical composition mass percentage of calcium magnesium phosphate fertilizer is: P 2 o 5 15.03%, MgO 18.16%, CaO 34.02%, SiO 2 28.25%, Fe 2 o 3 4.45%, Mn 0.0653%, Cu 0.0214%, Co 0.0015%, Mo 0.0018%, the total amount is 100%; finally shake the shaking reactor at 25°C for 1h, the shaking speed is 200rpm, after the shaking is completed, the reaction Filter the liquid-solid mixture in the filter to separate the solid and liquid, and return the obtained liquid to the liquid storage tank to avoid pollution; after the separated solid is collected, it is naturally air-dried at room temperature to obtain activated calcium magne...

Embodiment 2

[0030] First prepare 20mmol / L oxalic acid solution, place it in the liquid storage tank, then add the oxalic acid solution in the liquid storage tank to the shaking reactor with calcium magnesium phosphate fertilizer, the liquid-solid ratio of oxalic acid solution to calcium magnesium phosphate fertilizer is 18ml : 1g, wherein the main chemical composition mass percentage of calcium magnesium phosphate fertilizer is: P 2 o 5 18.23%, MgO 16.08%, CaO 35.42%, SiO 2 26.02%, Fe 2 o 3 4.17%, Mn 0.0586%, Cu 0.0178%, Co 0.0024%, Mo 0.0012%, the total amount is 100%; finally shake the shaking reactor at 35°C for 1h, the shaking speed is 210rpm, after the shaking is completed, the reaction Filter the liquid-solid mixture in the filter to separate the solid and liquid, and collect the obtained liquid in the liquid storage tank to avoid pollution; after the separated solid is collected, it is naturally air-dried at room temperature to obtain activated calcium magnesium phosphate fer...

Embodiment 3

[0032]First prepare the tartaric acid solution of 25mmol / L, place it in the liquid storage tank, then add the tartaric acid solution in the liquid storage tank to the shaking reactor with calcium magnesium phosphate fertilizer, the liquid-solid ratio of tartaric acid solution and calcium magnesium phosphate fertilizer is 10ml : 1g, wherein the main chemical composition mass percentage of calcium magnesium phosphate fertilizer is: P 2 o 5 17.26%, MgO 19.08%, CaO 37.42%, SiO 2 23.06%, Fe 2 o 3 3.10%, Mn 0.0643%, Cu 0.0117%, Co 0.0025%, Mo 0.0015%, the total amount is 100%; finally shake the shaking reactor at 30°C for 1.5h, the shaking speed is 200rpm, after the shaking is completed, put The liquid-solid mixture in the reactor is filtered to separate the solid and liquid, and the obtained liquid is collected in the liquid storage tank to avoid pollution; after the separated solid is collected, it is naturally air-dried at room temperature to obtain activated calcium magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com