Method for obtaining refined extract from capparis spinosa and application of extract

A technology of capers and extracts, which is applied in the field of natural medicinal chemistry, can solve the problems that are not conducive to industrial production, the chemical composition of the active part is not clear, and the process is cumbersome, so as to achieve the effect of being beneficial to ecological balance, clear chemical composition and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

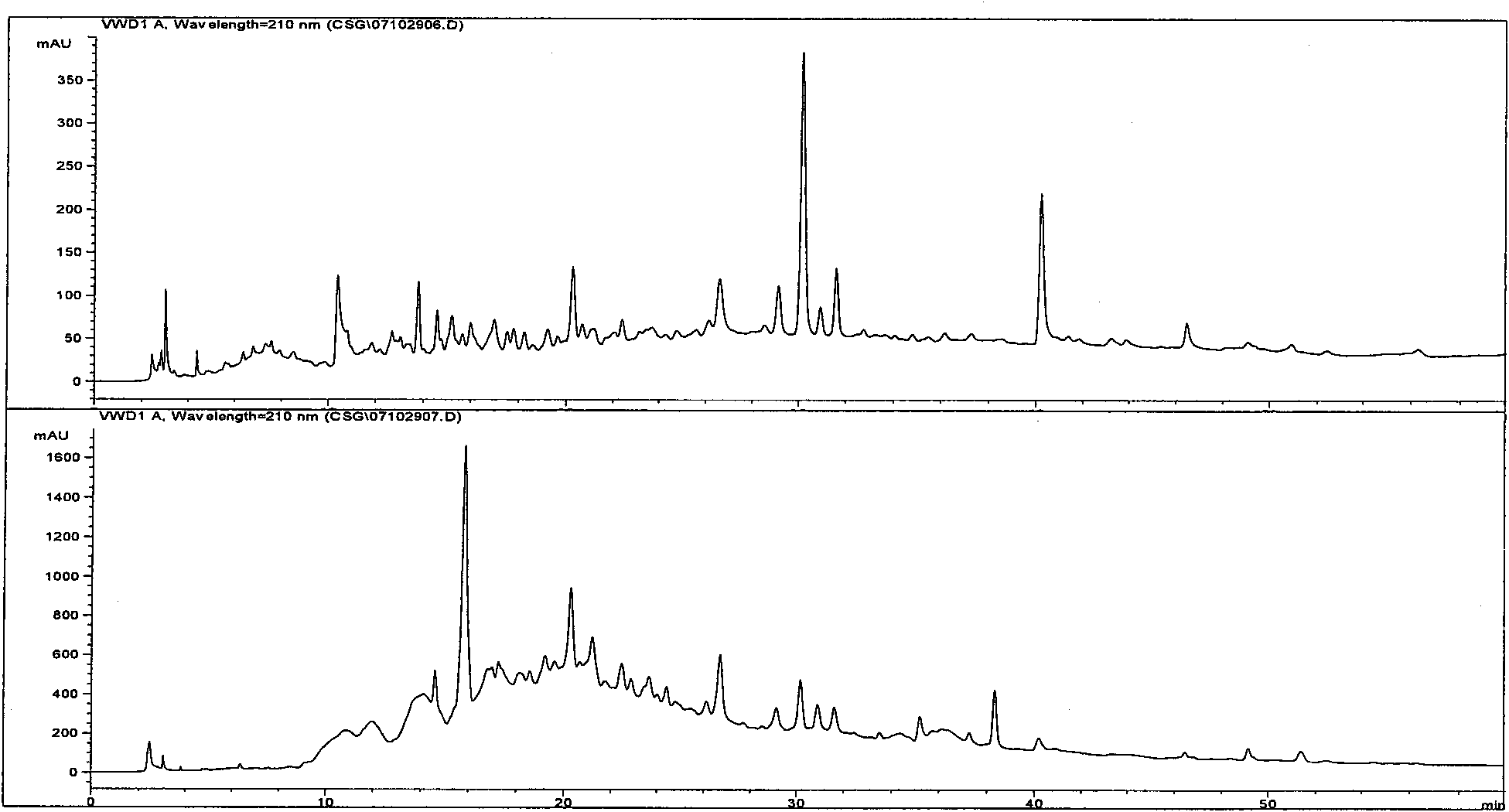

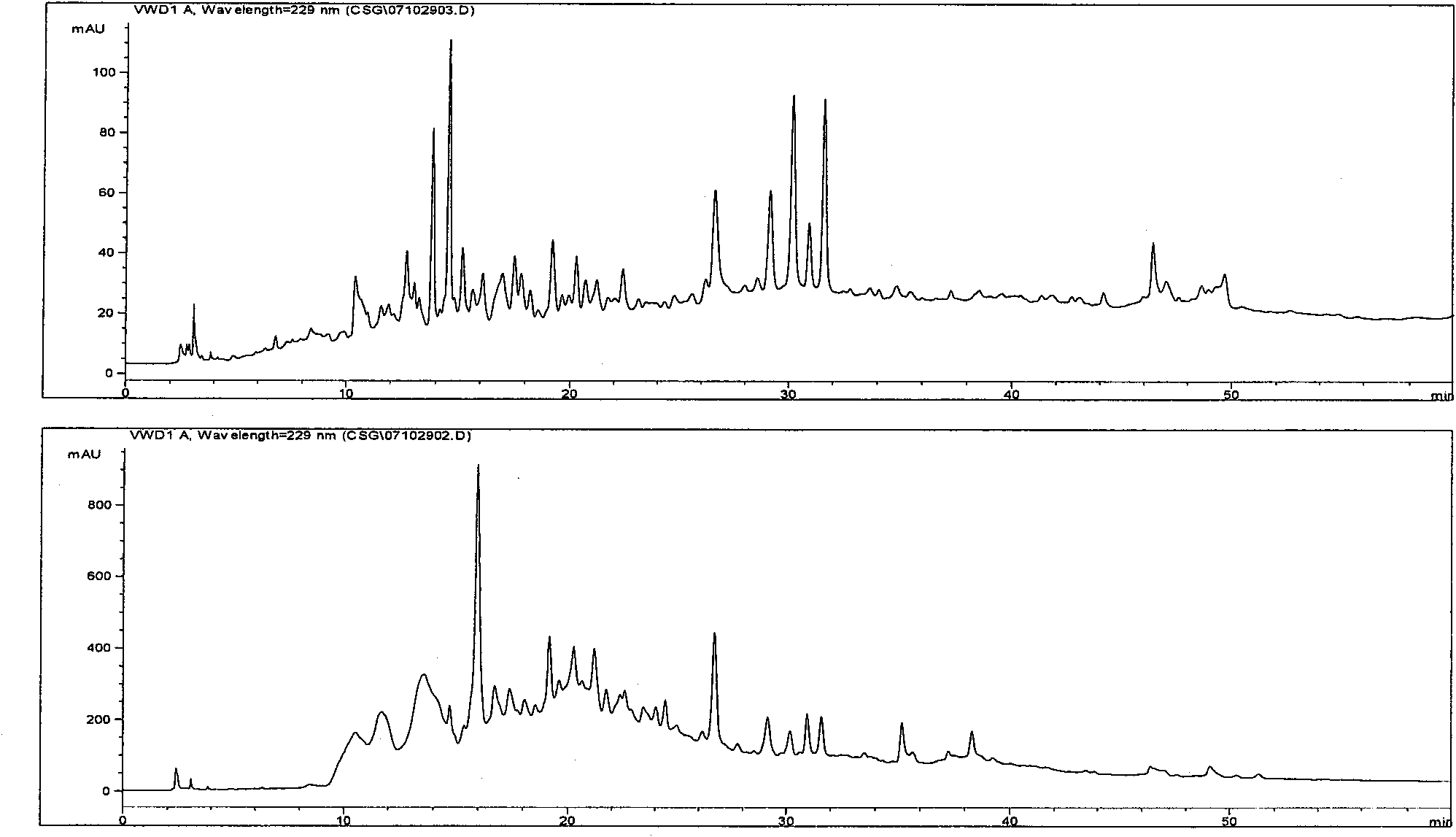

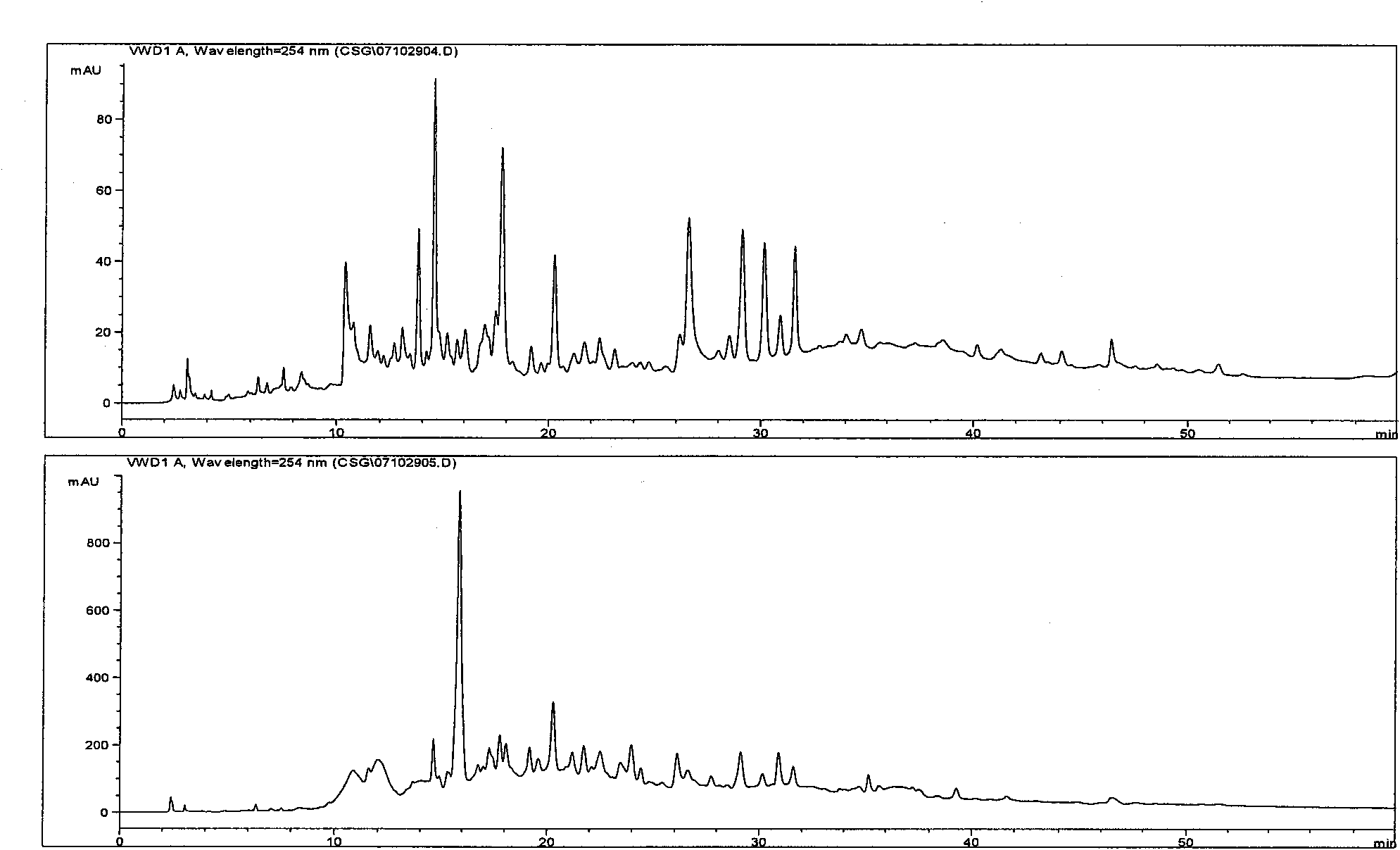

Image

Examples

Embodiment 1

[0082] Capers dried fruit 1kg, pulverized, extracted with 8 times the volume of water, extracted twice, each time for 2 hours, filtered, and combined the two filtrates. Concentrate under reduced pressure to a concentration of about 1.2 g / ml. 95% ethanol was added to make the final alcohol concentration 70%, and the alcohol precipitation was allowed to stand overnight. Filtrate to obtain the filtrate, concentrated under reduced pressure to no alcohol smell, this solution was passed through 860021 type macroporous adsorption resin, followed by water, 30%, 50%, 70%, 95% ethanol (both volume ratio) elution, to obtain water Part 131.5g, 30% ethanol part 14.70g, 50% ethanol part 3.328g, 70% ethanol part 1.304g, 95% ethanol part 0.66g.

Embodiment 2

[0084] Capers dried fruit 1kg, pulverized, extracted with 8 times the volume of water, extracted twice, each time for 2 hours, filtered, and combined the two filtrates. Concentrate under reduced pressure to a concentration of about 1.2 g / ml. 95% ethanol was added to make the final alcohol concentration 70%, and the alcohol precipitation was allowed to stand overnight. Filtrate was obtained by filtration, concentrated under reduced pressure to no alcohol smell, passed this solution through 860021 macroporous adsorption resin, and eluted with water, 30%, 70%, and 95% ethanol (both by volume ratio) successively to obtain 129.8 g of the water part , 30% ethanol part 13.6g, 70% ethanol part 4.2g, 95% ethanol part 0.59g.

Embodiment 3

[0086] Capers dried fruit 1kg, crushed, extracted with 8 times the volume of 75% ethanol, heated and refluxed twice, each time refluxed for 2 hours, heated and refluxed twice, each time refluxed 2 hours, filtered, combined twice filtrate. Concentrate until there is no alcohol smell, add an appropriate amount of ethanol solution, and dilute to a certain volume of 30% ethanol solution. This solution was passed through 860021 type macroporous adsorption resin, followed by gradient elution with water, 30%, 70%, 95% ethanol (both volume ratios), to obtain 78.8g of the water part, 12.2g of the 30% ethanol part, and 70% ethanol Part 8.54g, 95% ethanol part 3.4g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com