Chemical material finished product dehydration tank

A dehydration tank and material technology, applied in the direction of drying solid materials, non-progressive dryers, dryers, etc., can solve the problems of inability to dehydrate chemical materials and waste energy, save energy consumption, speed up dehydration, prevent heat The effect of air diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

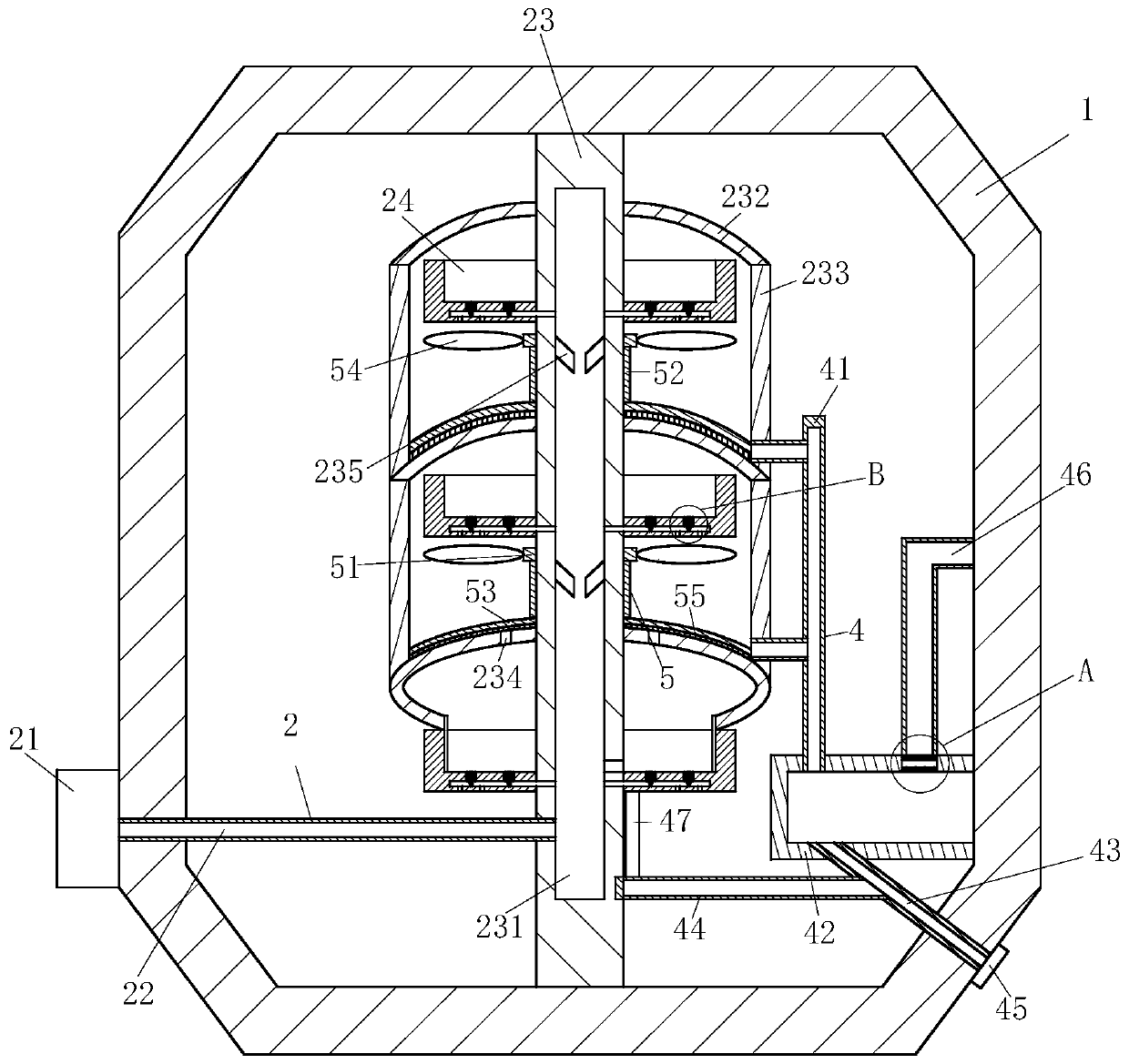

[0019] use Figure 1-Figure 4 A chemical material product dehydration tank according to an embodiment of the present invention is described as follows.

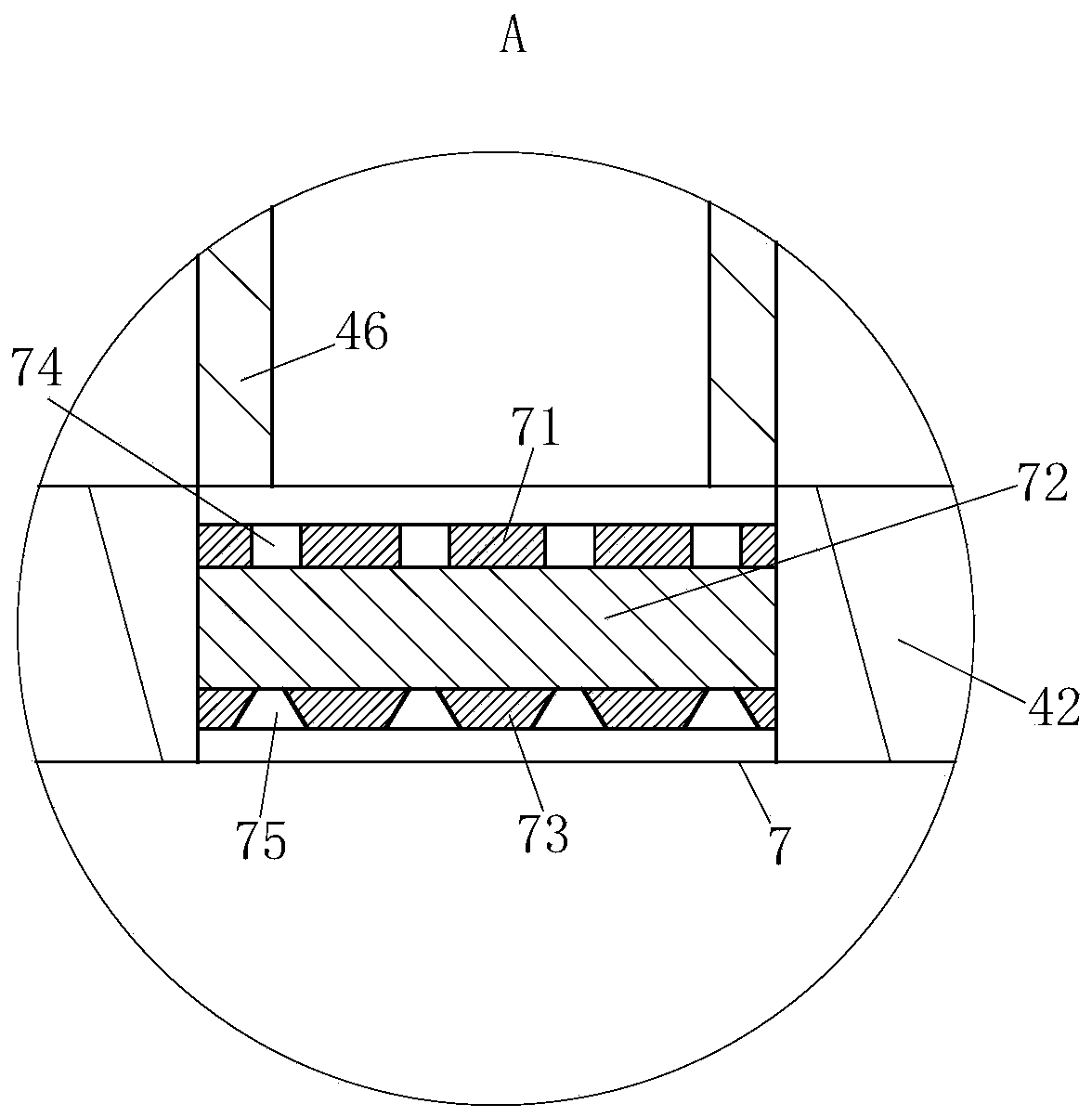

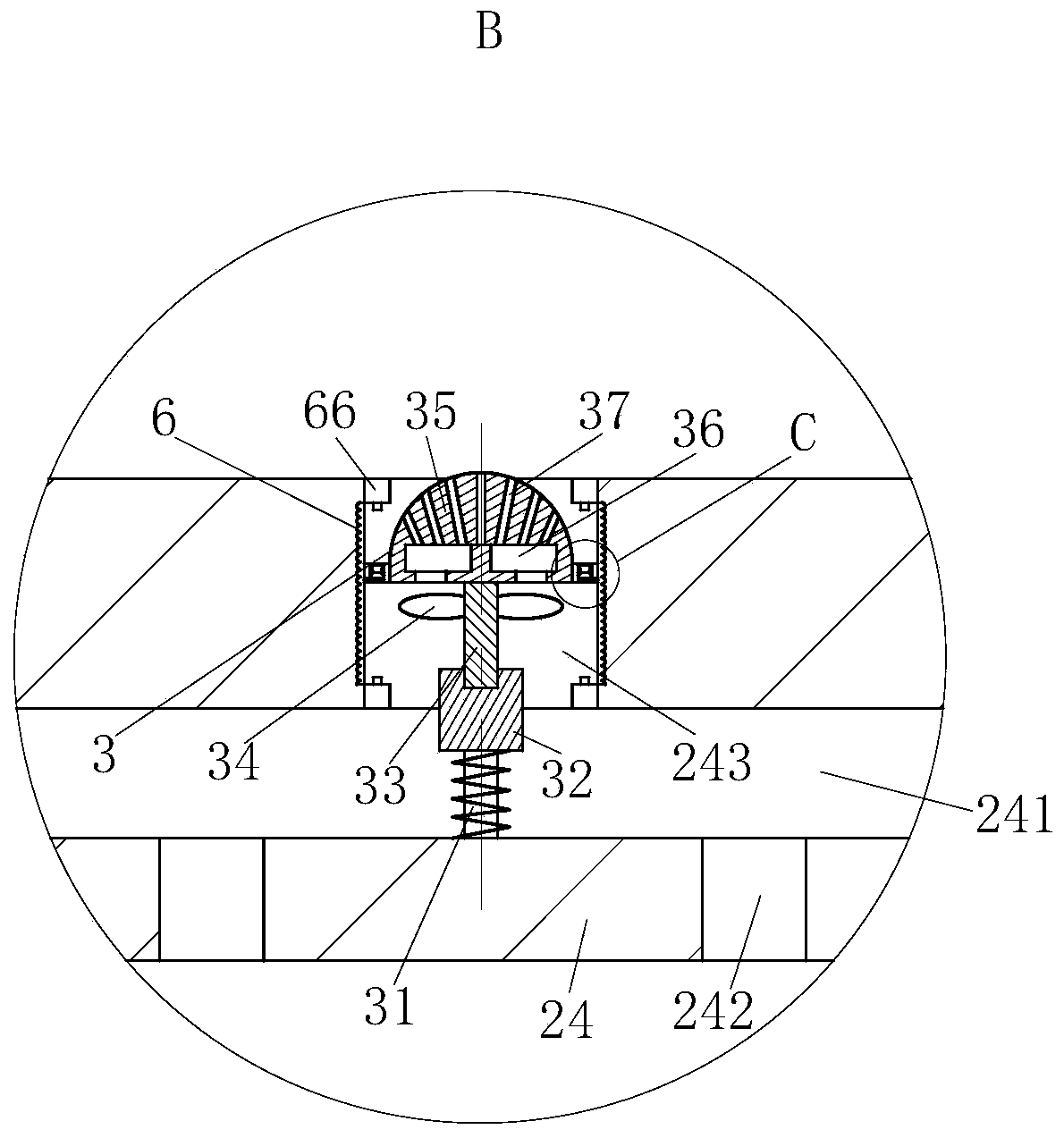

[0020] Such as Figure 1-Figure 4 As shown, a dehydration tank for finished chemical materials according to the present invention includes a frame body 1, an air transmission mechanism 2, a diffuser mechanism 3, an air outlet mechanism 4, an ash removal mechanism 5, a circulation mechanism 6 and a filter mechanism 7; The air delivery mechanism 2 comprises a hot air blower 21, an air delivery pipe 22 and a dispersing rod 23; the hot air blower 21 is fixedly mounted on the outer surface of the left end lower side of the frame body 1, and the right end of the hot air blower 21 is fixedly connected with an air delivery pipe 22; the air delivery pipe The right end of 22 is fixedly interspersed and connected in the lower end wall of the dispersing rod 23; the upper and lower ends of the dispersing rod 23 are vertically fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com