Imbalance detection washing machine and imbalance detection method

A technology for balance detection and washing machines, applied in the field of washing machines, can solve problems such as inability to accurately measure and control, reduce the service life of washing machines, and affect the life of mechanical structures, and achieve the effects of being suitable for popularization and use, improving dehydration efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

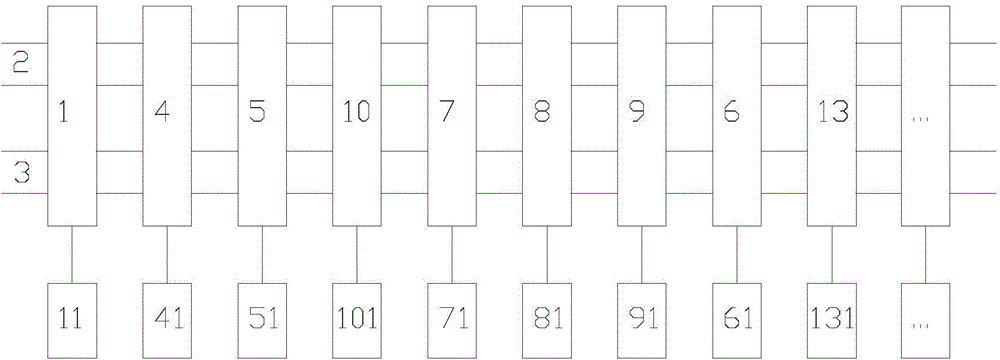

[0077] As a preferred embodiment of the present invention: the function control module further includes: one of door lock control module 6, drying control module 7, automatic delivery control module 8, heating control module 9 or a combination of at least two.

[0078] As a preferred embodiment of the present invention, the load of the drying control module 7 is each drying assembly 71 constituting the clothes drying system of the washing machine; the drying control module 7 can be set on an independent circuit board or located on the control circuit board. Preferably, the drying control module 7 is an intelligent control computer board installed near the drying assembly for controlling the working state of the drying assembly 71 of the washing machine. The intelligent control computer board forming the drying control module 7 is directly connected with the drying assembly.

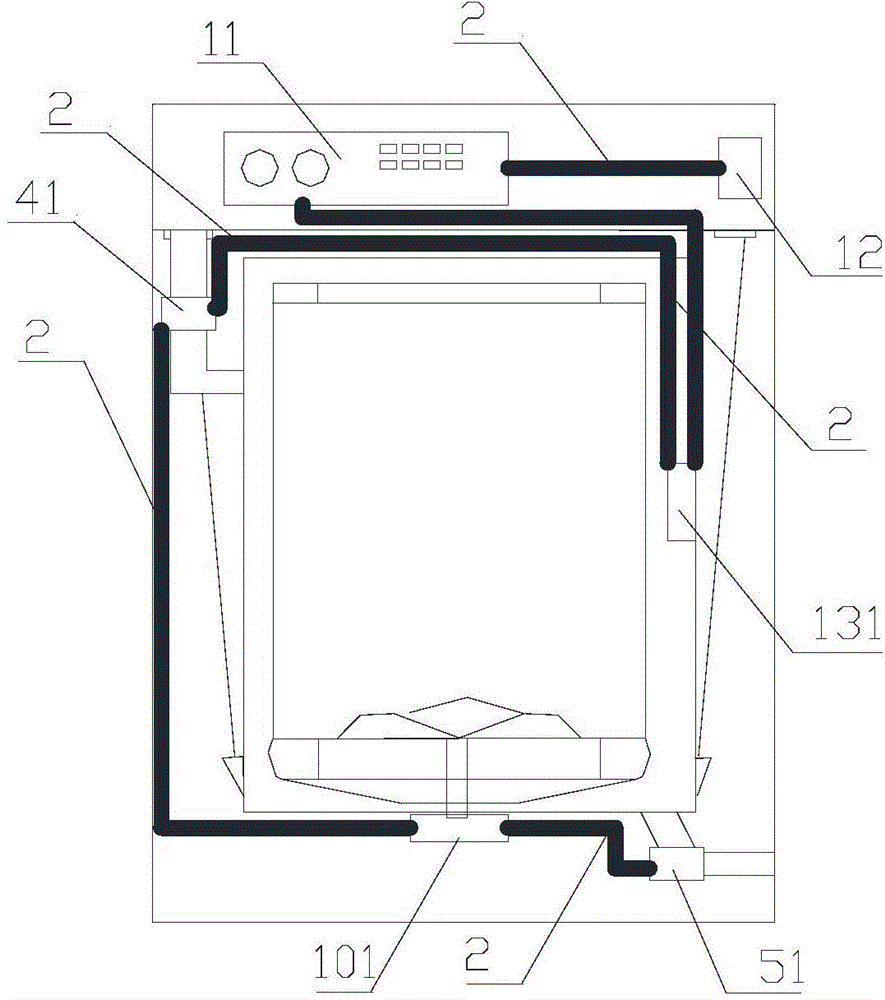

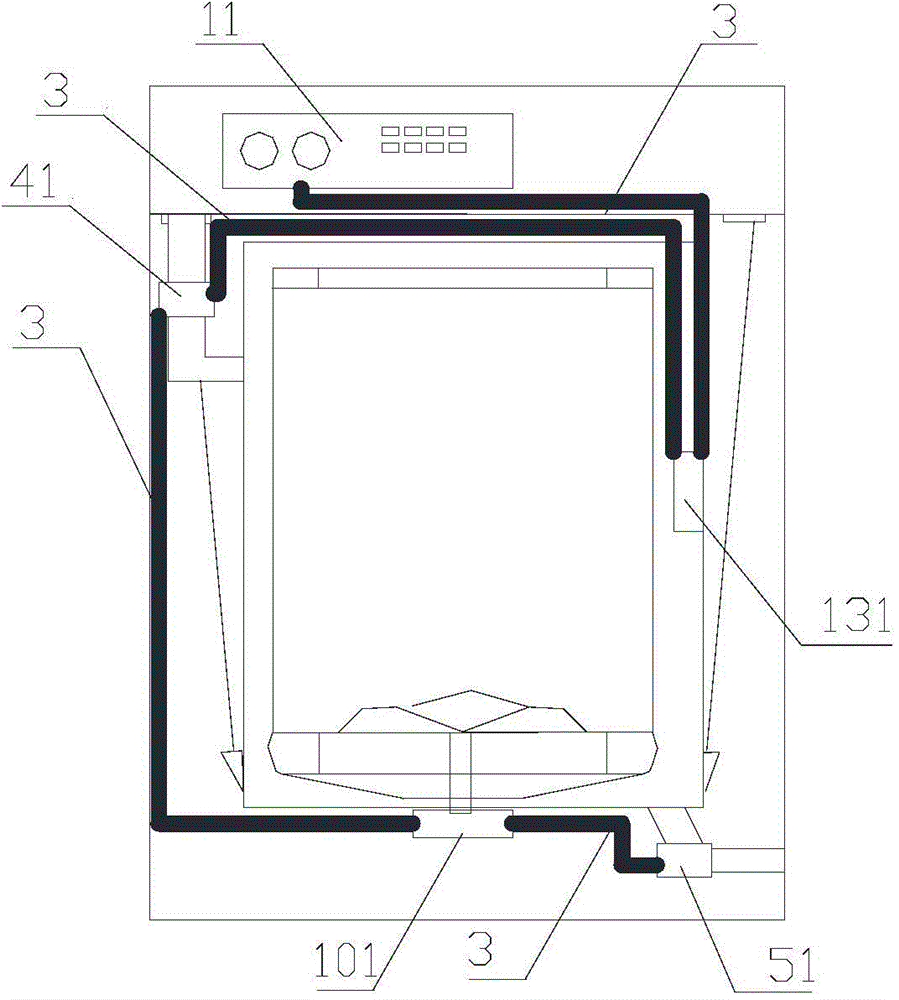

[0079] In this embodiment, the data bus 3 passes through the control panel 11 , the drying assembly 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com