Dewatering distributed control method of washing machine

A distributed control, washing machine technology, applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of displacement, low energy consumption, non-drying and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

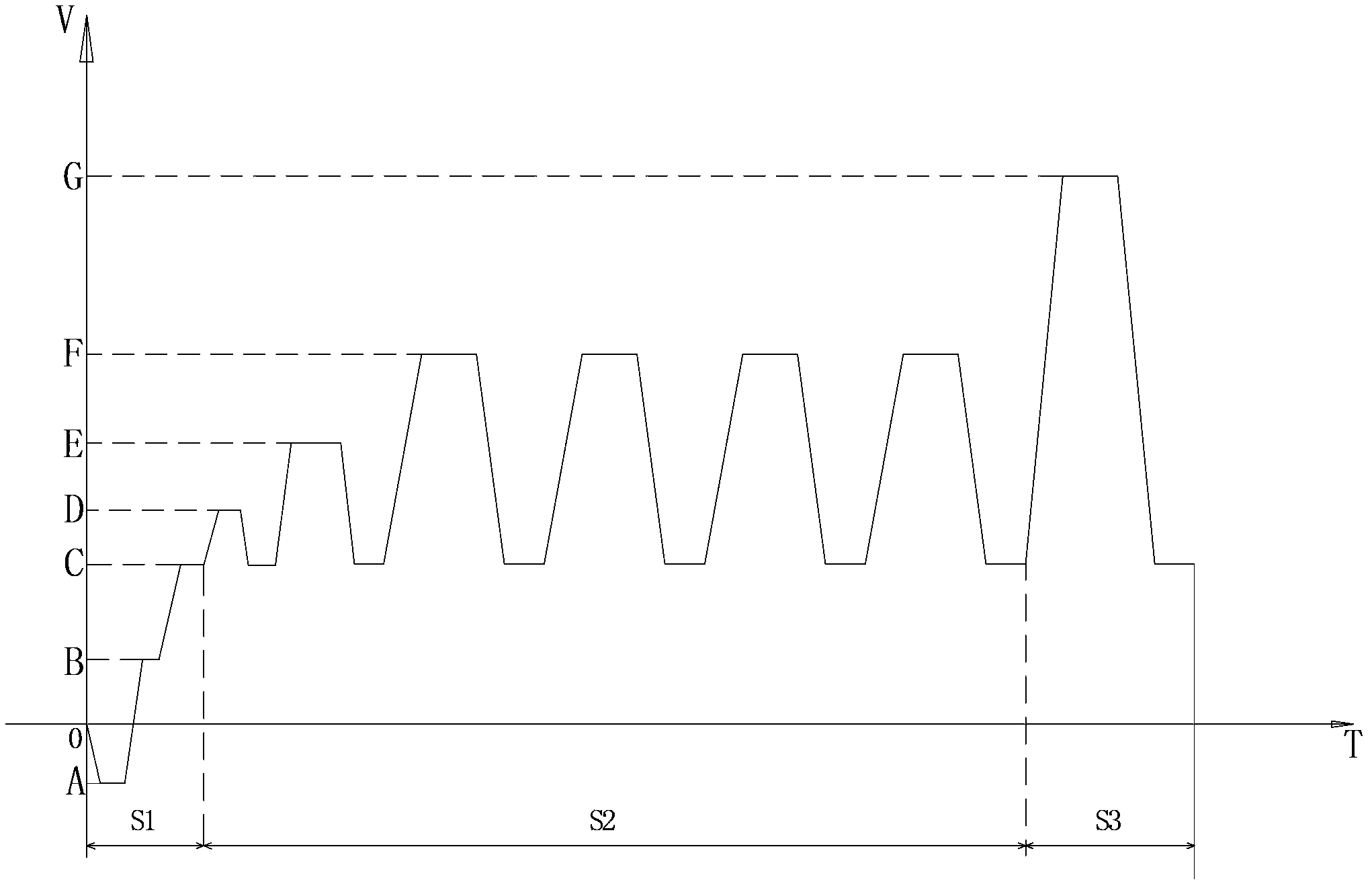

[0045] Such as figure 1 As shown, the dehydration distribution of the washing machine according to the present invention includes an initial stage of confirming the eccentricity value S1, a process of repeatedly confirming the eccentricity value of the load S2, and a speed fluctuation value detection process S3.

[0046] The initial stage of confirming the eccentricity value is: controlling the inner cylinder to reverse at the speed V8 for a certain period of time, rotating forward to the speed V9 and maintaining it for a certain period of time, and then increasing to the speed V1, detecting the maximum speed of the inner cylinder in one revolution, The maximum speed must be within a certain range, otherwise it will return to forward or reverse according to the system judgment, detect the eccentricity value P1 of the load, and compare it with the system preset eccentricity limit X1. The detected eccentricity value P1 must be less than the system preset eccentricity limit Value, ot...

Embodiment 2

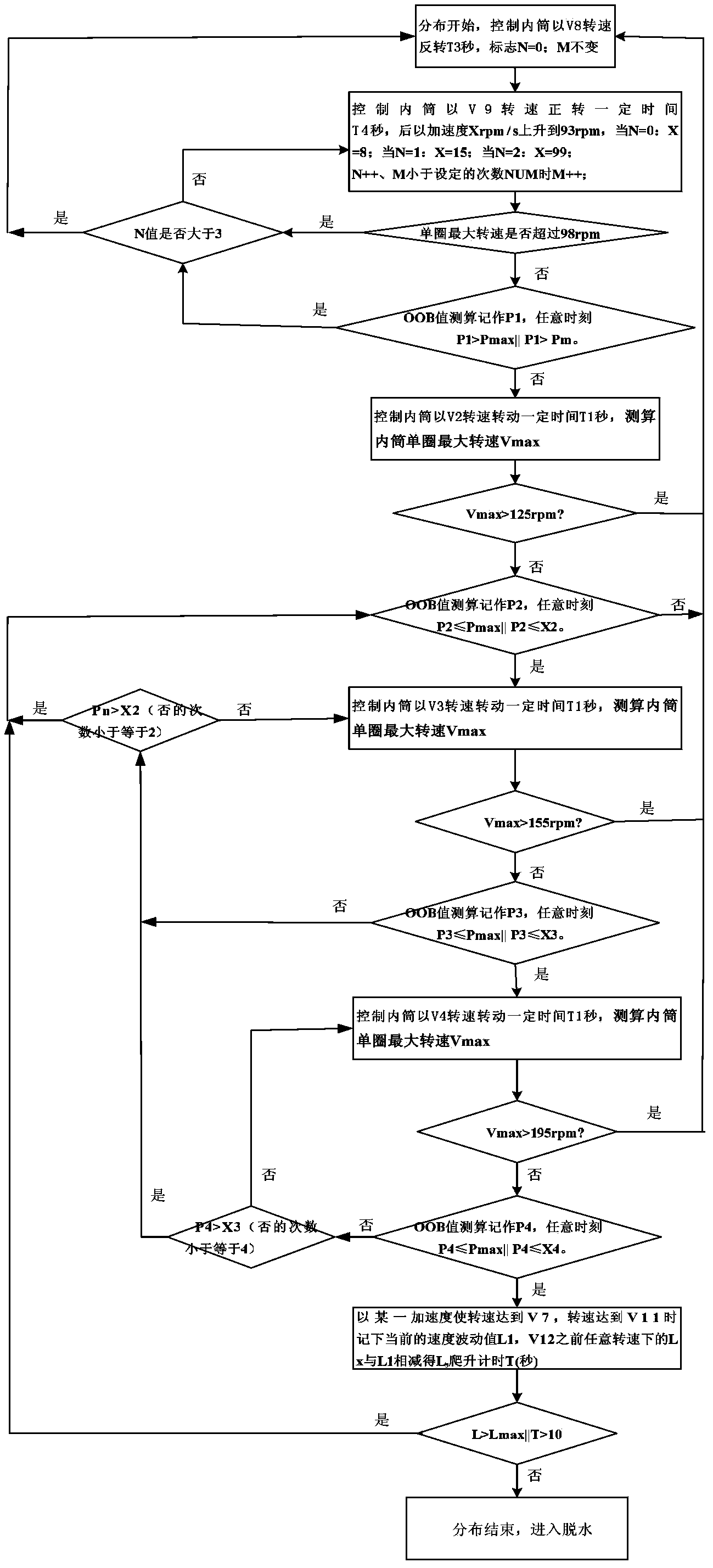

[0059] Specific as figure 2 As shown, the distribution control method before washing machine dehydration includes the following steps:

[0060] Set N and M represent the mark code in the program, N represents the corresponding times of changing the acceleration value in a single distribution, M represents the corresponding times of changing the set eccentric value in the distribution, that is, N is the number of times to return to the second stage, M It is the number of times through the second stage in a distribution, initial value: N=0; M=0, return to step (1), N returns to zero, the value of M remains unchanged, the maximum value of N can be set to 3, the maximum value of M For the system setting, the system sets the eccentricity value corresponding to the M value.

[0061] (1) Control the inner cylinder to reverse for 6 seconds at a speed of 50 revolutions per minute to prevent winding when the load rotates in one direction. At this time, N=0, M remains unchanged;

[0062] (2)...

Embodiment 3

[0076] The distribution before dehydration is a random process, and the time required cannot be accurately predicted. In the flow chart of the washing machine, the time is usually not allocated in advance, that is, the time is stopped during the distribution. However, in order to prevent the distribution from being unsuccessful and the process from running downwards, an untimed limit can be implemented. In principle, this time is specified as 5 minutes (adjustable depending on different programs and the highest set speed), that is, when the distribution time exceeds 5 minutes If it is still unsuccessful, the timing will be forced to start, and the inherent dehydration time will be occupied thereafter, until the dehydration time is also used up, the distribution before this dehydration fails, and the next process is transferred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com