New method for deeply dewatering sludge through bio-leaching process rapid conditioning

A technology of biological leaching and deep dehydration, applied in the field of environmental treatment, can solve the problems of long reaction time and poor dehydration effect, and achieve the effects of easy evaporation, simple process and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Enrichment, domestication and inoculum preparation of composite microbial flora

[0034] The strains used for sludge bioleaching are thiobacillus thioooxidans TS6, thiobacillus ferrooxidans LX5, Pichia pastoris P.spartinae D13, Geotrichum Galactomyces sp.Z3, and Rhodotorula mucilaginosaR30. Put the above-mentioned strains in their respective medium (Thiobacillus thiooxidans TS6 medium g / L: (NH 4 ) 2 SO 4 0.4, KH 2 PO 4 3.0, MgSO 4 ·7H 2 O0.5, CaCl 2 ·2H 2 O0.25, sulfur powder 10; Thiobacillus ferrooxidans LX5 medium g / L: (NH 4 ) 2 SO 4 3.5, KCl0.119, K 2 HPO 4 0.58, Ca(NO 3 ) 2 ·4H 2 O0.168, MgSO 4 ·7H 2 O0.583, FeSO 4 ·7H 2 O4.42, use 10N H 2 SO 4 Adjust the pH to 2.5; Pichia pastoris D13, red yeast R30 and geotrichum Z3 medium g / L: potato 200, sucrose or glucose 20, use 10N H 2 SO 4 Adjust the pH to 2.5) for culture expansion (placed in a reciprocating shaker at 28°C and shake culture at 180 rpm until the number of bacterial cells reaches 10 8 / ML), and then mix...

Embodiment 2

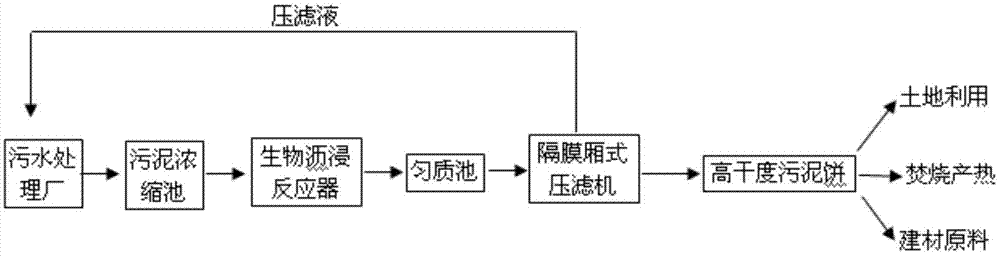

[0035] Example 2: Biological leaching conditioning of sludge from a municipal sewage treatment plant in Nanjing

[0036] According to the process mentioned in the present invention, according to the process (see attached figure 1 ) Treatment of sludge from a municipal sewage treatment plant in Nanjing. The sewage treatment process of the sewage treatment plant is the activated sludge method. The sludge has not been anaerobic or aerobic digested. Take about 10 tons of concentrated sludge with a solid content of 4.46%, and the basic properties of the liquid sludge are determined to be The pH value is 7.26, the organic matter is 52.9%, and the sludge specific resistance is 1.50×10 13 m kg -1 , It is extremely difficult to dehydrate, and has a foul smell.

[0037] Biological leaching stage: Add the inoculum and the sludge to be treated into the biological leaching reactor according to the volume ratio of the inoculum and the sludge to be treated at 1:9, and add the biological leachin...

Embodiment 3

[0039] Example 3: Biological leaching conditioning of sludge from a sewage treatment plant in Wuxi

[0040] According to the process mentioned in the present invention, according to the process (see attached figure 1 ) Treatment of sludge from a municipal sewage treatment plant in Wuxi. The sewage treatment process of the sewage treatment plant is the activated sludge method. The sludge has not been treated by anaerobic or aerobic digestion. About 10 tons of concentrated sludge from the plant was taken, and the basic property of the liquid sludge was determined to be 7.52. Organic matter is 48.3%, total nitrogen is 4.78%, total phosphorus is 3.00%, high calorific value is 10.4MJ / kg, heavy metals are not exceeded, and the specific resistance of sludge is 2.05×10 13 m kg -1 , It is extremely difficult to dehydrate, and has a foul smell. Before conditioning, the sludge was diluted to a solid content of 2%, 3%, 4% and 5%, and the specific resistance of the sludge was determined to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com