Process and device for processing smoke containing sulfur dioxide and preparing solid ammonium sulfate

A technology of sulfur dioxide and ammonium sulfate, which is applied in the direction of ammonium sulfate, chemical instruments and methods, and the separation of dispersed particles, which can solve problems such as increased operating costs, unfavorable environmental protection, and increased ammonia escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

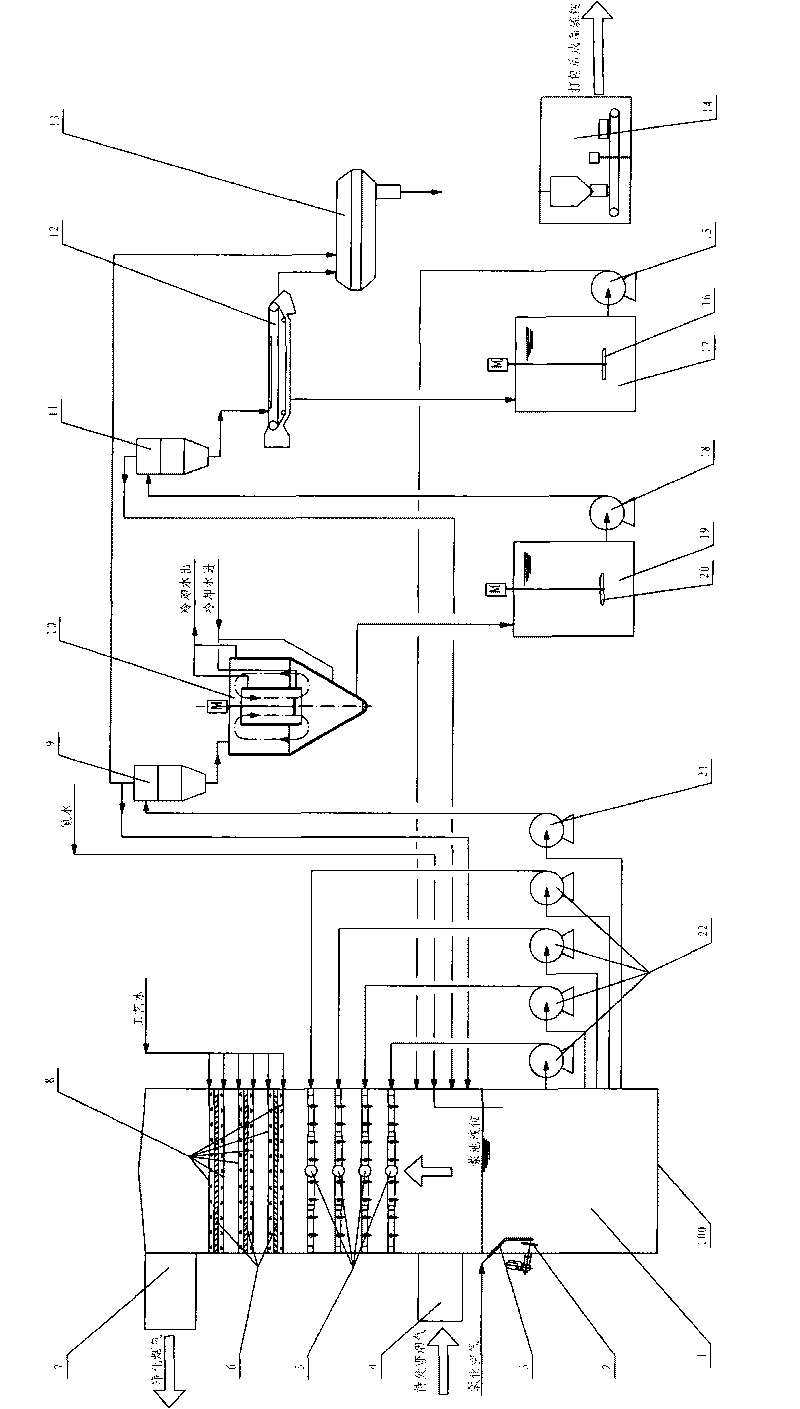

[0114] Embodiment 1, the technical process and device structure adopted in this embodiment are as attached figure 1 shown.

[0115] Raw flue gas from the boiler with a flow rate of 100×10 4 N m 3 / h, the temperature is 150 degrees Celsius, and the sulfur dioxide content is 2000mg / Nm 3 , the dust concentration is 100mg / Nm 3 , enters from the original flue gas inlet in the middle of the absorption tower, then flows upwards, and undergoes countercurrent washing of two layers of slurry sprayed down, in which SO 2 into the slurry. The flow velocity of flue gas through the absorption tower is 3.5m / s. The washed flue gas is treated by the 3-layer horizontal demister at the top of the absorption tower, and the fine mist droplets entrained in the flue gas are removed, and then discharged from the system through the outlet at the top of the absorption tower. The temperature of the net flue gas discharged from the system is about 55 degrees, SO 2 The content is 100mg / Nm 3 , the d...

Embodiment 2

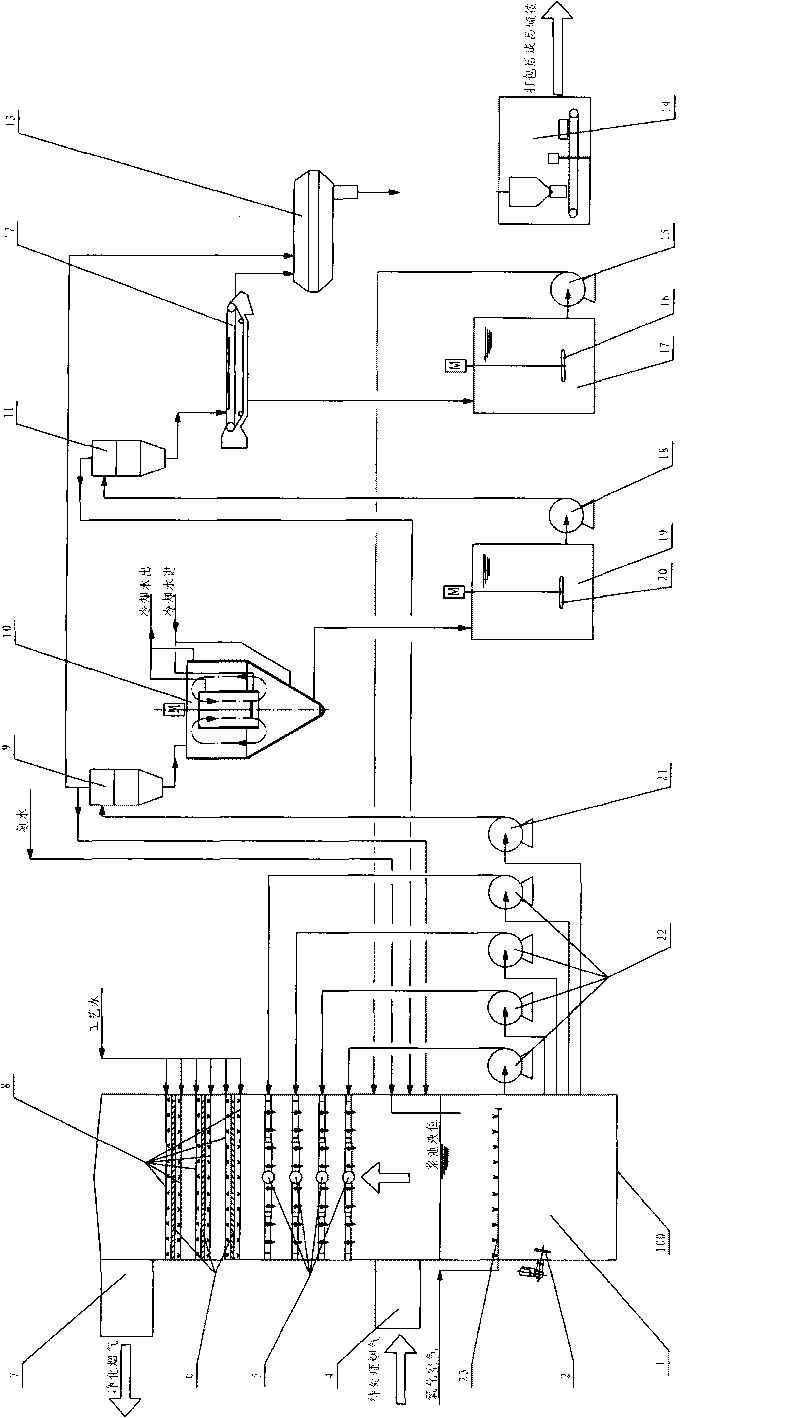

[0141] Embodiment 2, the technical process and device structure adopted in this embodiment are as attached figure 2 shown. This embodiment has many similarities with Embodiment 1, and only the differences from Embodiment 1 will be described below.

[0142] The original flue gas flow rate of this embodiment is 200×10 4 N m 3 / h, the temperature is 140 degrees Celsius, and the sulfur dioxide content is 4000mg / Nm 3 , there are 3 layers of spraying in the absorption tower, the flow velocity of the flue gas flowing through the absorption tower is 3.8m / s, the net flue gas temperature of the discharge system is about 48 degrees, SO 2 The content is 100mg / Nm 3 , equipped with 3 circulating pumps, the injection of oxidation air adopts the pipe network method, and the distance between the air outlet of the oxidation air pipe network and the liquid surface of the slurry tank of the absorption tower is 5.5m.

[0143] The spray layer of this embodiment includes 3 layers of spray lay...

Embodiment 3

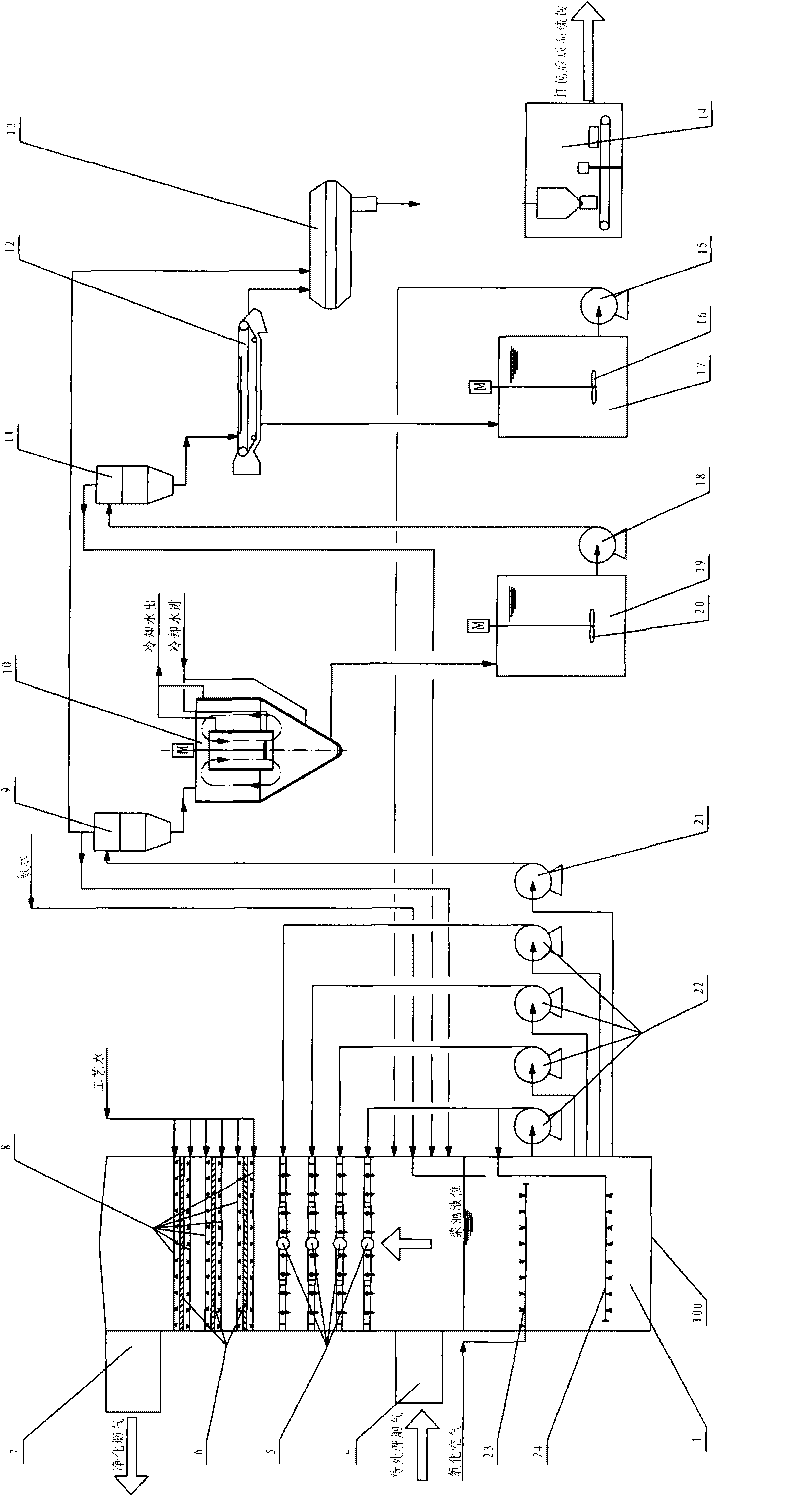

[0148] The technical process and device structure adopted in this embodiment are as attached image 3 shown. This embodiment has many similarities with Embodiment 1, and only the differences from Embodiment 1 will be described below.

[0149] The original flue gas flow rate of this embodiment is 300×10 4 N m 3 / h, the temperature is 140 degrees Celsius, and the sulfur dioxide content is 8000mg / Nm 3 , there are 4 layers of spraying in the absorption tower, the flow velocity of the flue gas flowing through the absorption tower is 3.9m / s, the net flue gas temperature of the discharge system is about 49 degrees, SO 2 The content is 100mg / Nm 3 , equipped with 4 circulating pumps, the injection of oxidizing air adopts the pipe network method, there is no agitator in the slurry pool of the absorption tower, and a circulating pump is used to transport part of the slurry back to the absorption tower to prevent the solid ammonium sulfate in the slurry pool from settling.

[0150] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com