Method for producing semicoke briquette coal based on dry biomass binder

A production method and biomass technology, applied in the field of coal chemical industry, can solve the problems of low strength of finished balls, long kneading time, poor mixing controllability, etc. Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

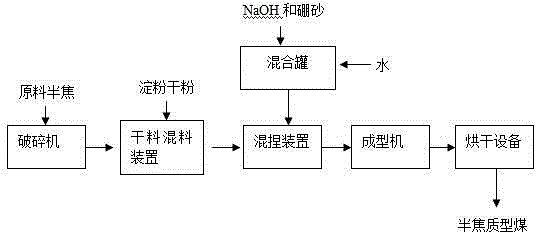

[0023] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] The biomass binder in the present invention is prepared by a dry method. The so-called dry method means that the raw material starch does not need to be mixed with water first to prepare the starch dairy industry, but is directly mixed with the raw material semi-coke to achieve uniform dehydration, the briquette is not easy to crack, and the whole ball high rate effect.

[0025] The dry-process binder of the present invention firstly mixes dry starch powder and solid raw materials fully, then mixes the additive aqueous solution into the mixture, and adds in batches, since the starch dry powder can be precisely controlled by a quantitative scale, and the additive aqueous solution is Pure solution state, constant density, good fluidity, the flow can be precisely controlled by a flow meter, therefore, the precise control of the amount of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com