Pulp forming mold integrally turning automat and production process thereof

A pulp molding and production process technology, used in textiles and papermaking, etc., can solve the problems of uneven quality, uneven thickness, and difficulty of obtaining finished products, and achieve the effects of uniform thickness, smooth surface, and reduced color difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

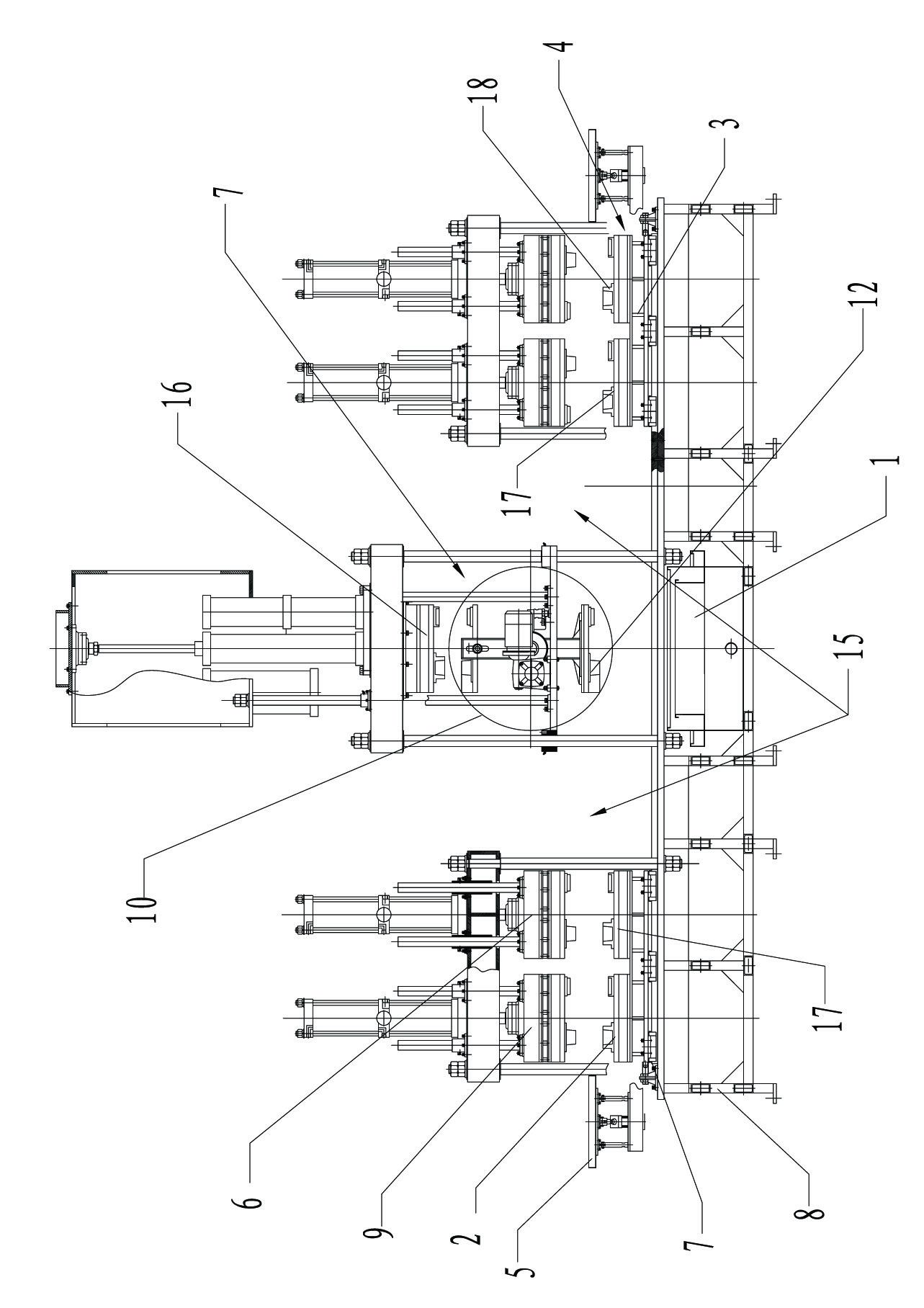

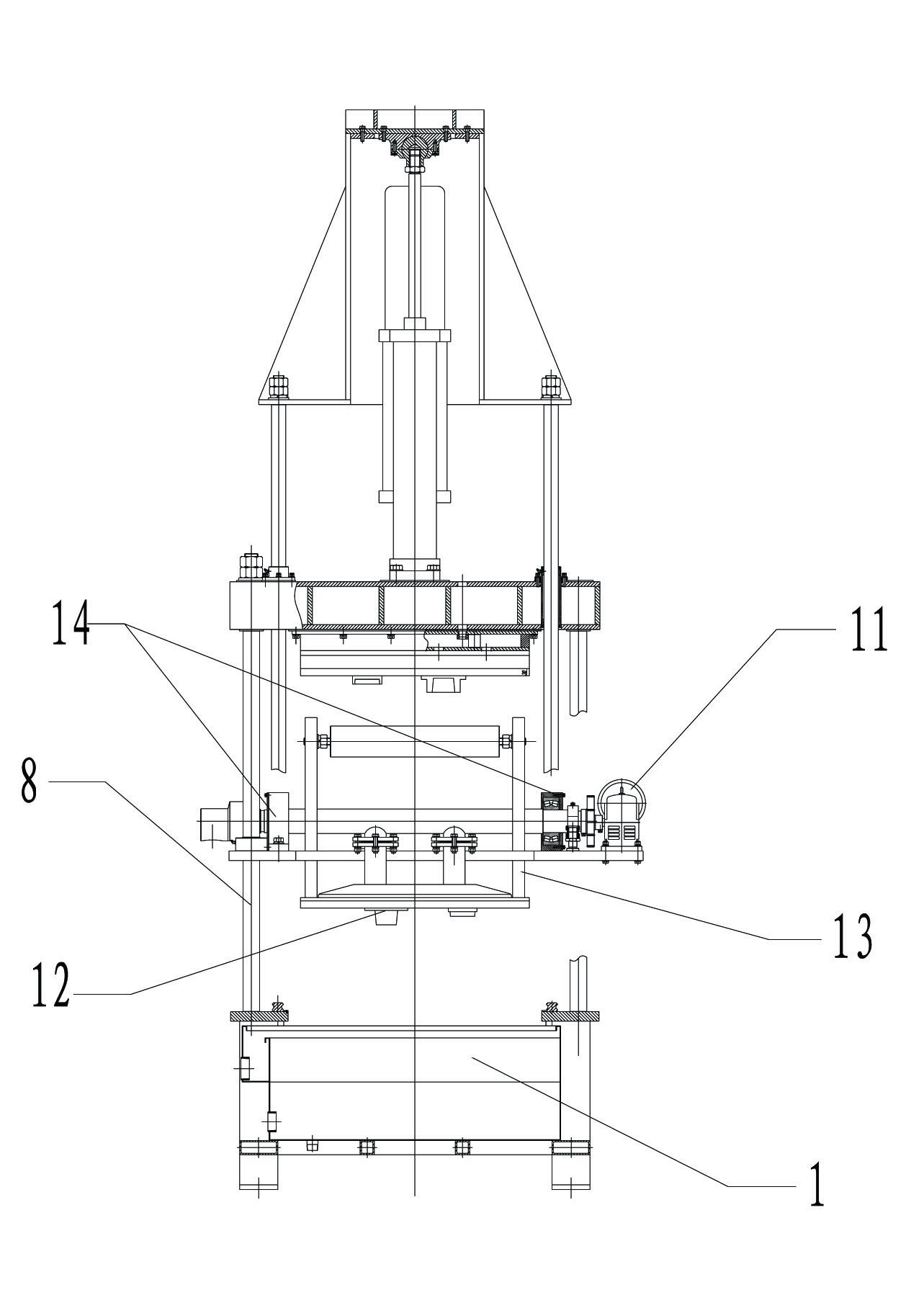

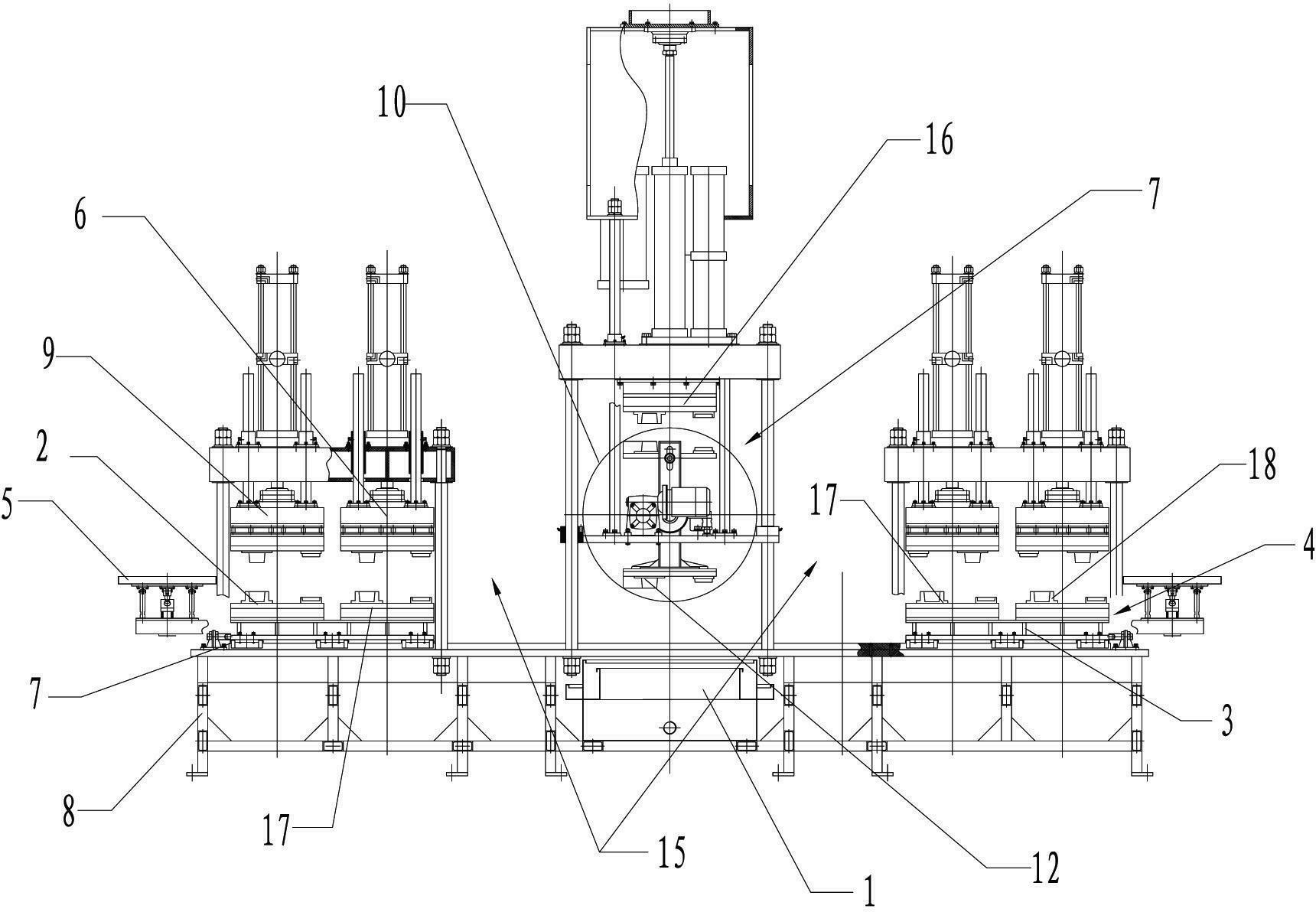

[0015] According to attached figure 1 And attached figure 2 As shown, the pulp molding integrated turning automatic machine described in this embodiment includes a pulp box 1, a moving device 4, a receiving frame 5, a hot-pressing upper mold 6 with vacuum adsorption, a forming mold device 7, and a frame 8 And be installed on the upper frame 8 and place side by side the material transfer mold 9 with vacuum suction of the hot pressing upper mold 6 away from the side of the forming mold device 7, and be installed on the moving device 4 close to the end of the receiving rack 5 The second hot-pressing lower die 2 arranged side by side with the first hot-pressing lower die 17 along the moving direction of the moving device 4, and the second hot-pressing lower die 2 is matched with the material transfer die 9, and the material transfer Reserve a waiting position 15 that can fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com