Fermentation process of bean dregs

A fermentation process, soybean meal technology, applied in the field of fermentation, can solve the problems of long time required, low production efficiency, high moisture content of the product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Soybean meal fermentation process, soybean meal is fermented after soaking in water, adding strains and mixing, after fermentation, the material containing 50% to 70% of water is first extruded by an extruder to reduce the moisture content of the material to 30%; continue to process the material Send it to the tube bundle hot air dryer for drying, control the temperature of the tube bundle hot air dryer at 50°C, reduce the moisture content of the material to 25%, and then disperse the material through a disperser; then send it to the hot air dryer to dry the material, control the hot air The temperature inside the dryer is 50°C, so that the moisture contained in the material is reduced to 13%, and finally cooled by cold air to reduce the moisture to below 12%.

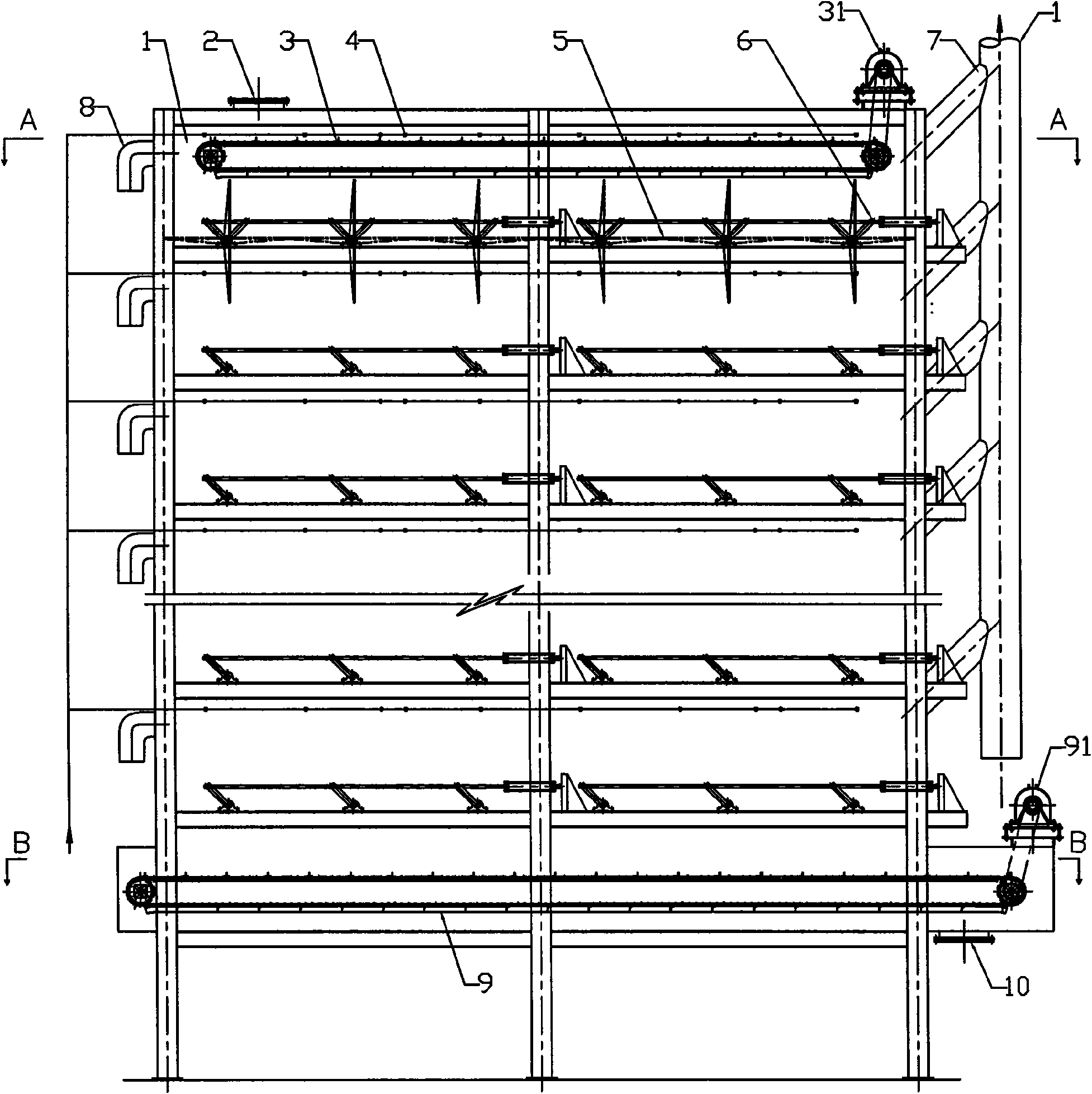

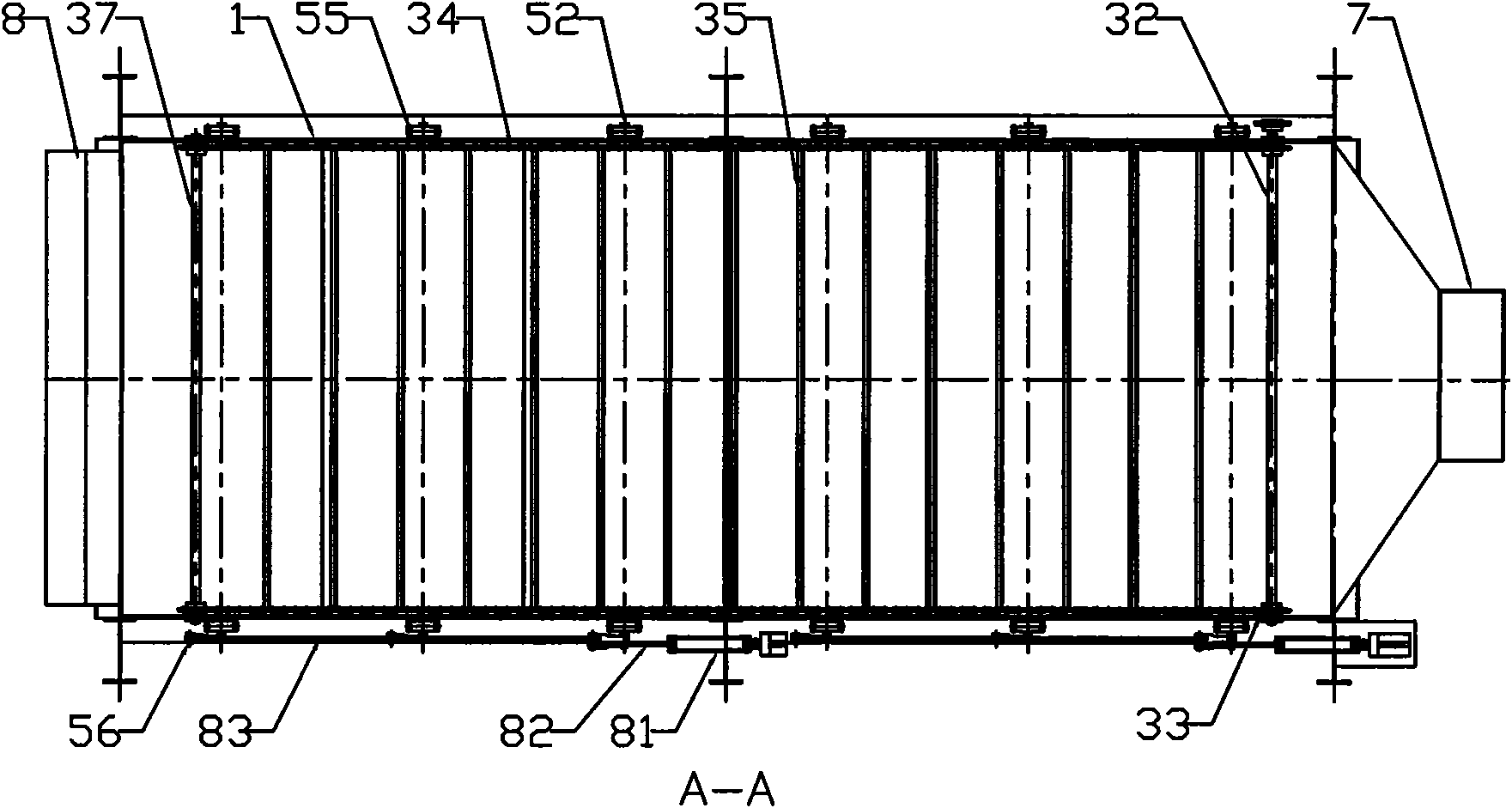

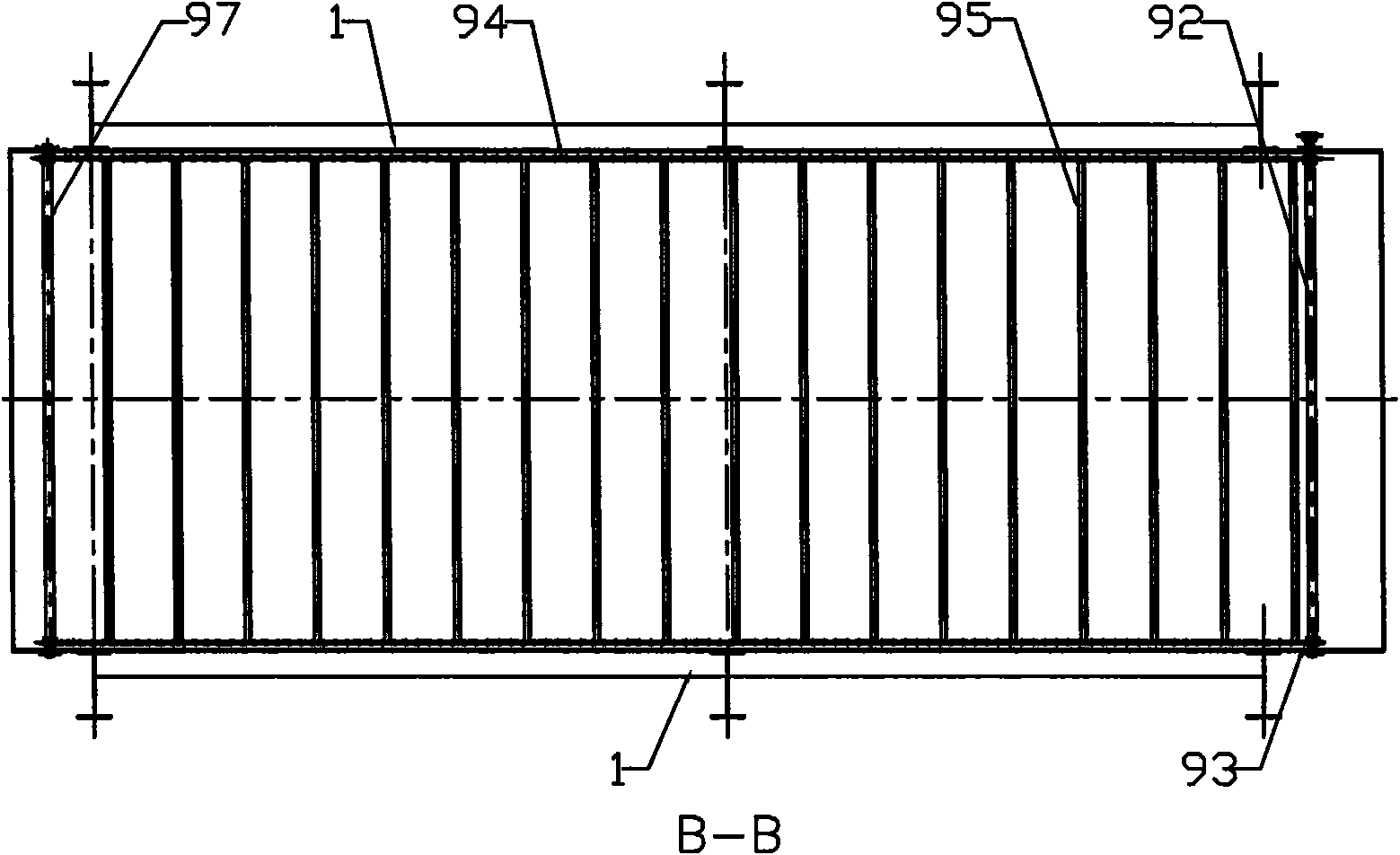

[0025] The device used during fermentation is a fermentation tower with multi-layer fermentation chambers, such as figure 1 , figure 2 and image 3 As shown, the fermentation tower includes a fe...

Embodiment 2

[0030] Example 2: Soybean meal fermentation process. Soybean meal is soaked in water, mixed with strains and then fermented. The fermented material is first extruded by an extruder to reduce the moisture content of the material to 35%; continue to send the material into the tube bundle for hot air drying Machine drying, control the temperature of the tube-bundle hot air dryer at 60°C to reduce the moisture content of the material to 27%; The moisture is reduced to 14%, and finally the moisture is reduced to below 12% by cold air cooling.

[0031] Fermentation apparatus and fermentation process are identical with embodiment 1.

Embodiment 3

[0032] Example 3: Soybean meal fermentation process, the soybean meal is soaked in water, mixed with bacteria and then fermented. The fermented material is first extruded by an extruder to reduce the moisture content of the material to 40%; continue to send the material into the tube bundle for hot air drying Machine drying, control the temperature of the tube bundle hot air dryer to 70°C, reduce the moisture content of the material to 30%, and then disperse the material through a disperser; then send the material to the hot air dryer to dry the material, and control the moisture content in the hot air dryer The temperature is 70°C, so that the moisture contained in the material is reduced to 15%, and finally cooled by cold air to reduce the moisture to below 12%.

[0033] Fermentation apparatus and fermentation process are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com