Washing method of dish-washing machine, and said machine

A washing method and a dishwasher technology, which are applied in the direction of tableware washing machines/rinsing and washing machine parts, etc., can solve the problems of not being able to further increase the spraying intensity of nozzle water, increasing the spraying intensity of sprayers, and increasing water consumption, etc., to achieve shortening Increased operating time, cleaning effect, and reduced water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

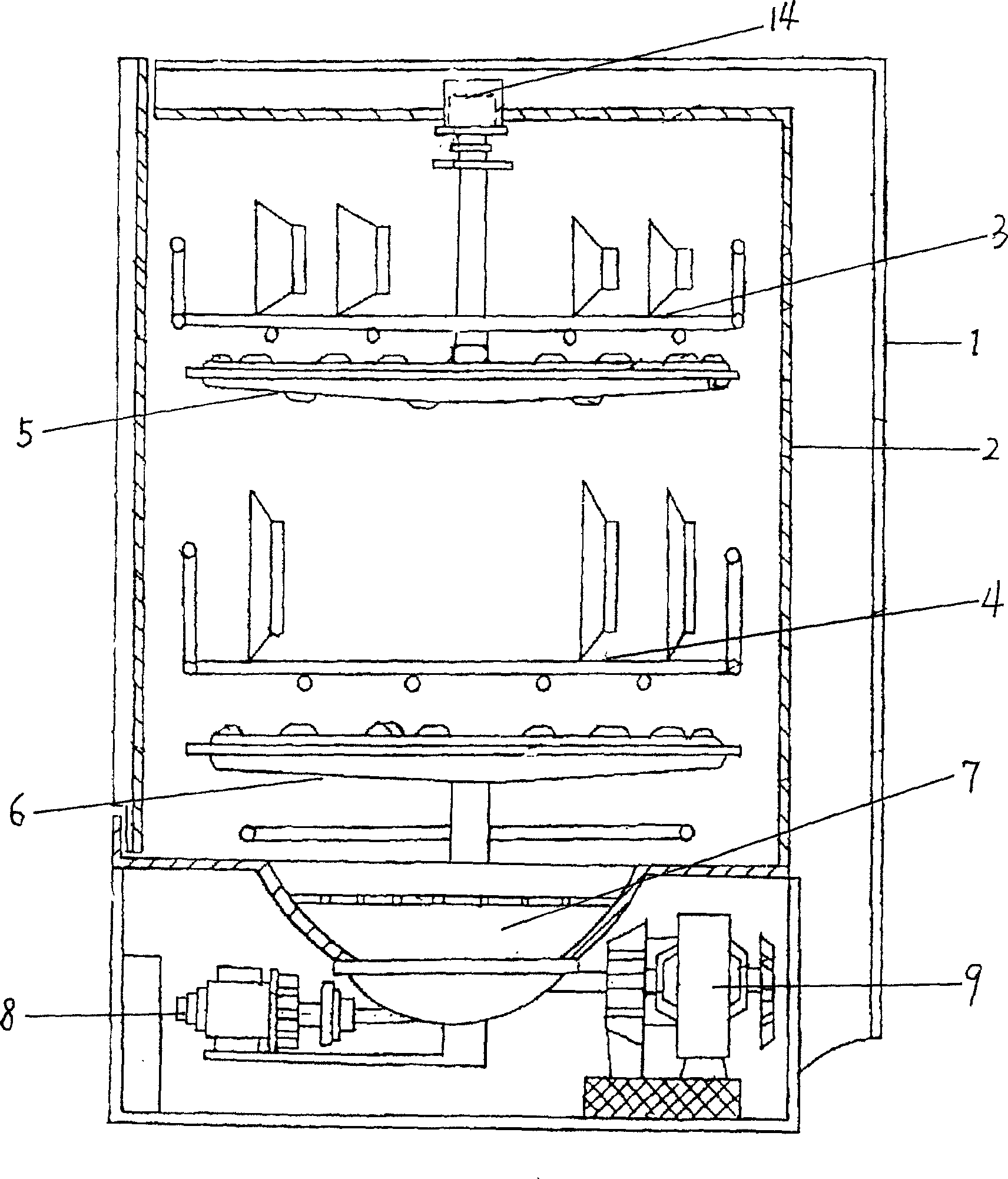

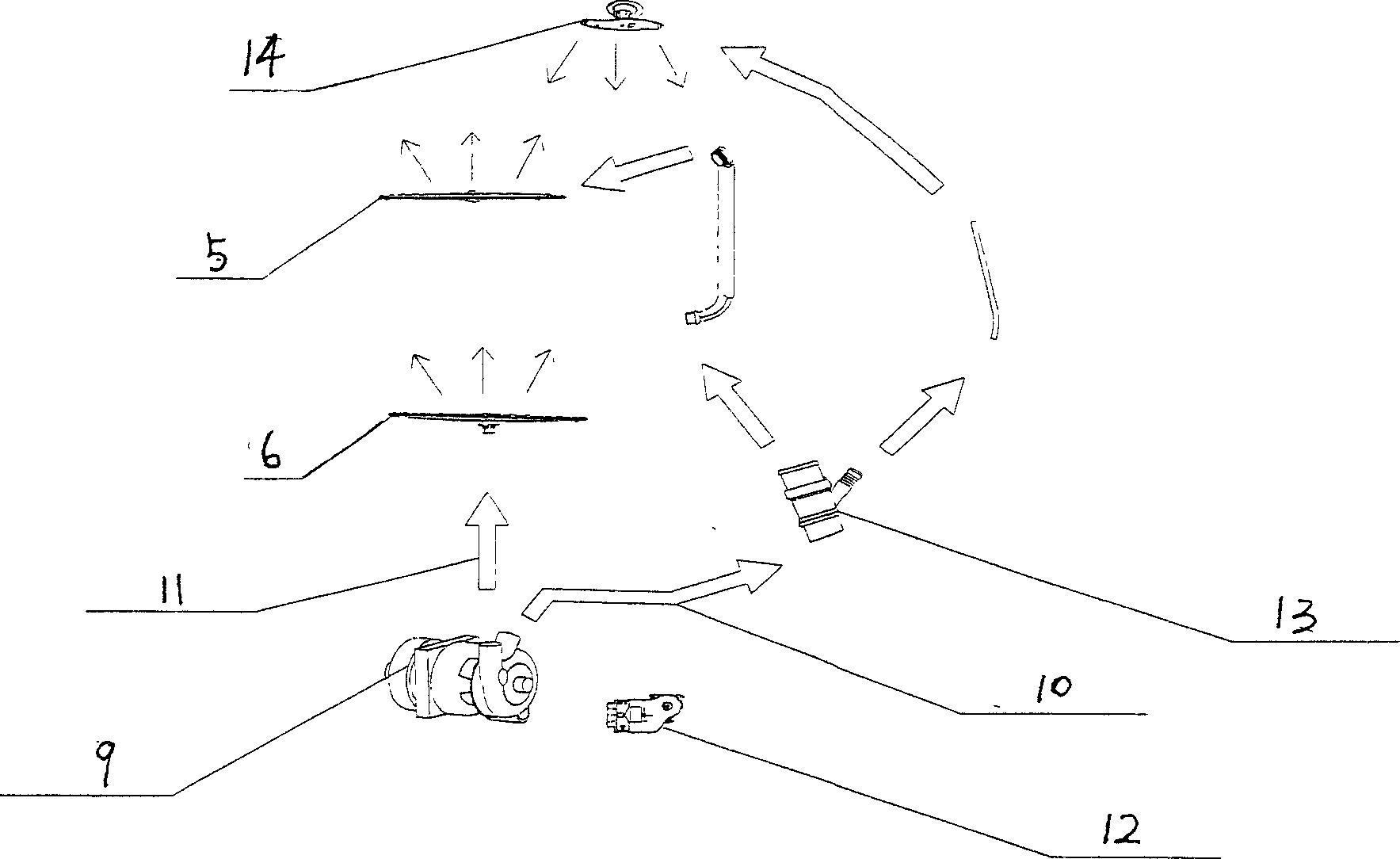

[0035] Embodiment 1: top wash

[0036] When there is only one layer of tableware on the tableware rack, if only the upper layer has tableware, only this layer should be washed. At this time, the computer board should control the water diversion plate to close the water channel 2, and only open the water channel 1, and the water diversion plate should stay at the A position.

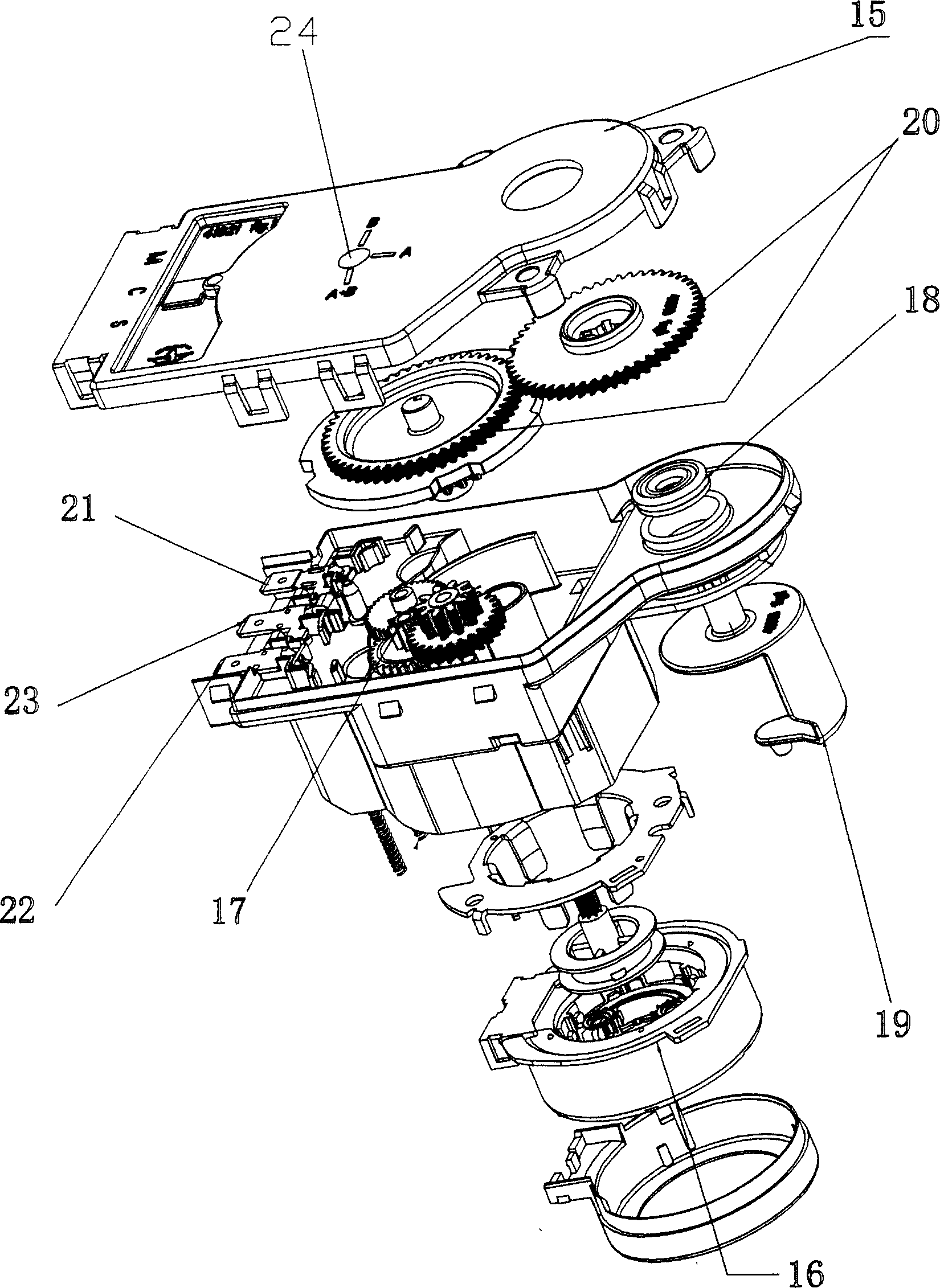

[0037] Turn on the power of the dishwasher, select the upper washing button on the control panel, the computer board sends instructions to the driving motor 16 of the pulser, the driving motor 16 drives the driving gear 17 to rotate, and the driving gear 17 drives the time control gear 20 through the meshing between the gears Rotate, thereby drive water diversion piece 19 to rotate. Assuming that the current pulsator water splitter 19 is in any position, the state of the pulse switch 25 may be open or closed. If the pulser needs to stop at the A position now, the drive motor 16 is supplied with power, an...

Embodiment 2

[0040] Embodiment 2: lower layer washing

[0041] When only the lower layer needs to be washed, the computer board controls the pulsator water diversion piece to close waterway 1 and waterway 2 to open, and the waterway piece should stay at position B.

[0042] Select the lower floor washing button on the control panel, and the computer board sends instructions to the driving motor of the pulser to rotate the water separator of the pulser. The principle is the same as that described in the above-mentioned embodiment, assuming that the current state of the water separator of the pulsator is in any position, the state of the pulse switch may be open or closed. If the pulsator needs to stop at position B, firstly The water sheet rotates and continues to rotate when it reaches the T (1 or 2 or 3) position. The pulse switch changes from off to on. At this time, the time starts to be counted. When the time from closing to off of the switch is T2 = 3.15 seconds, It can be determined...

Embodiment 3

[0044] Example 3: Pulse Wash

[0045] When both layers need to be washed, the dishwasher of the present invention can adopt the pulse washing method, that is, the upper and lower layers are washed in turn, and the upper layer is washed for a certain period of time, then the lower layer is washed for a certain period of time, and then the upper layer is washed for a certain period of time, and so on. to set the washing time.

[0046] At this time, the computer board needs to control the water diversion plate of the pulsator to close the waterway one or waterway two in turn according to the set time interval, that is, the water diversion plate should be located at position A or position B in turn. When the water diversion plate is located at A, when the water channel two is closed, the water channel one is opened, and the upper floor shower sprays water and detergent to the tableware on the tableware rack on the upper floor. After a certain period of time, the computer board co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com