Cardboard box printing grooving machine printing unit single scraping cutter device

A technology of carton printing and printing unit, which is applied in the field of single scraper device in the printing unit of carton printing slotting machine, which can solve the problems of excessive water consumption, affecting printing plate inking, and insufficient use of ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

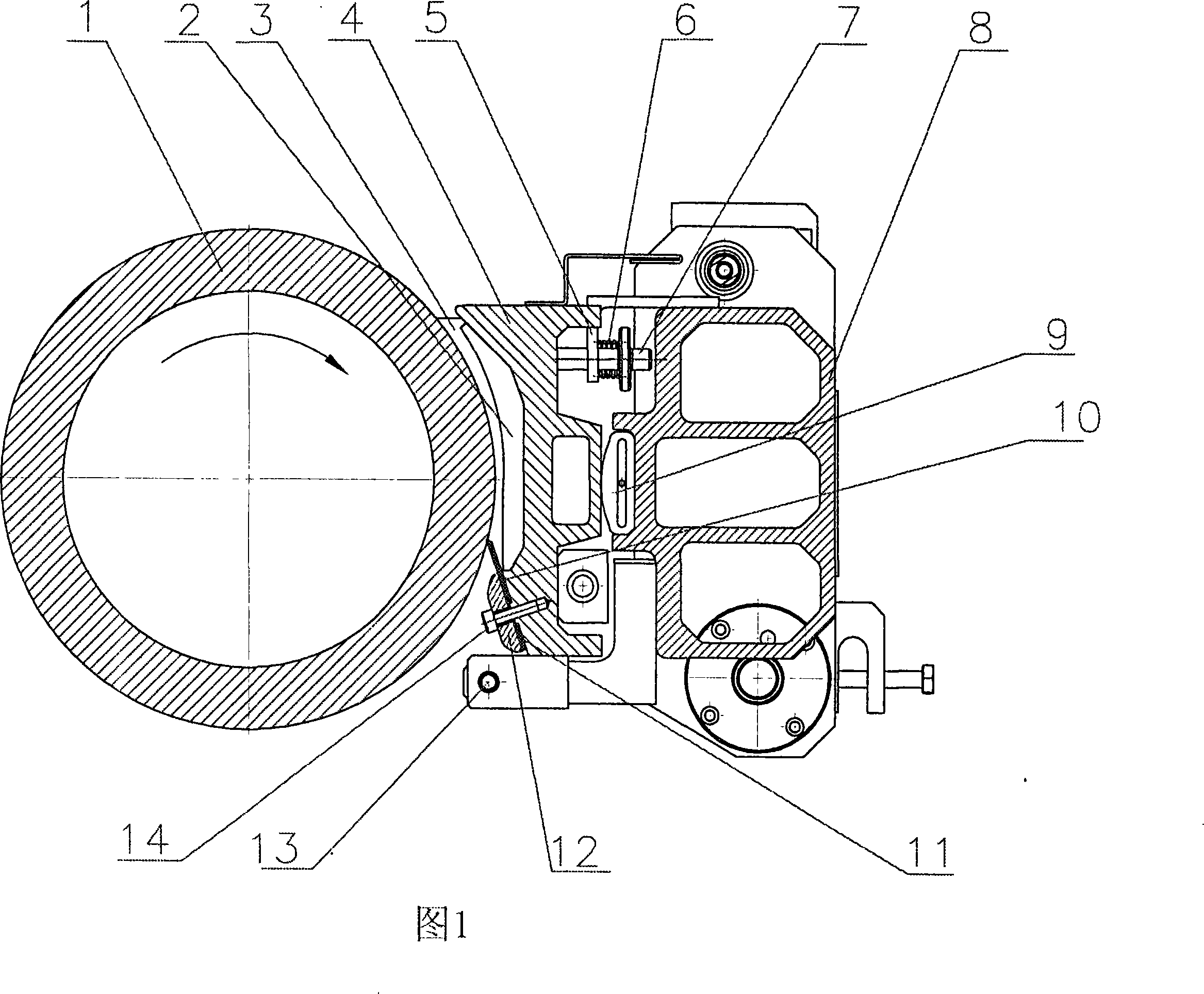

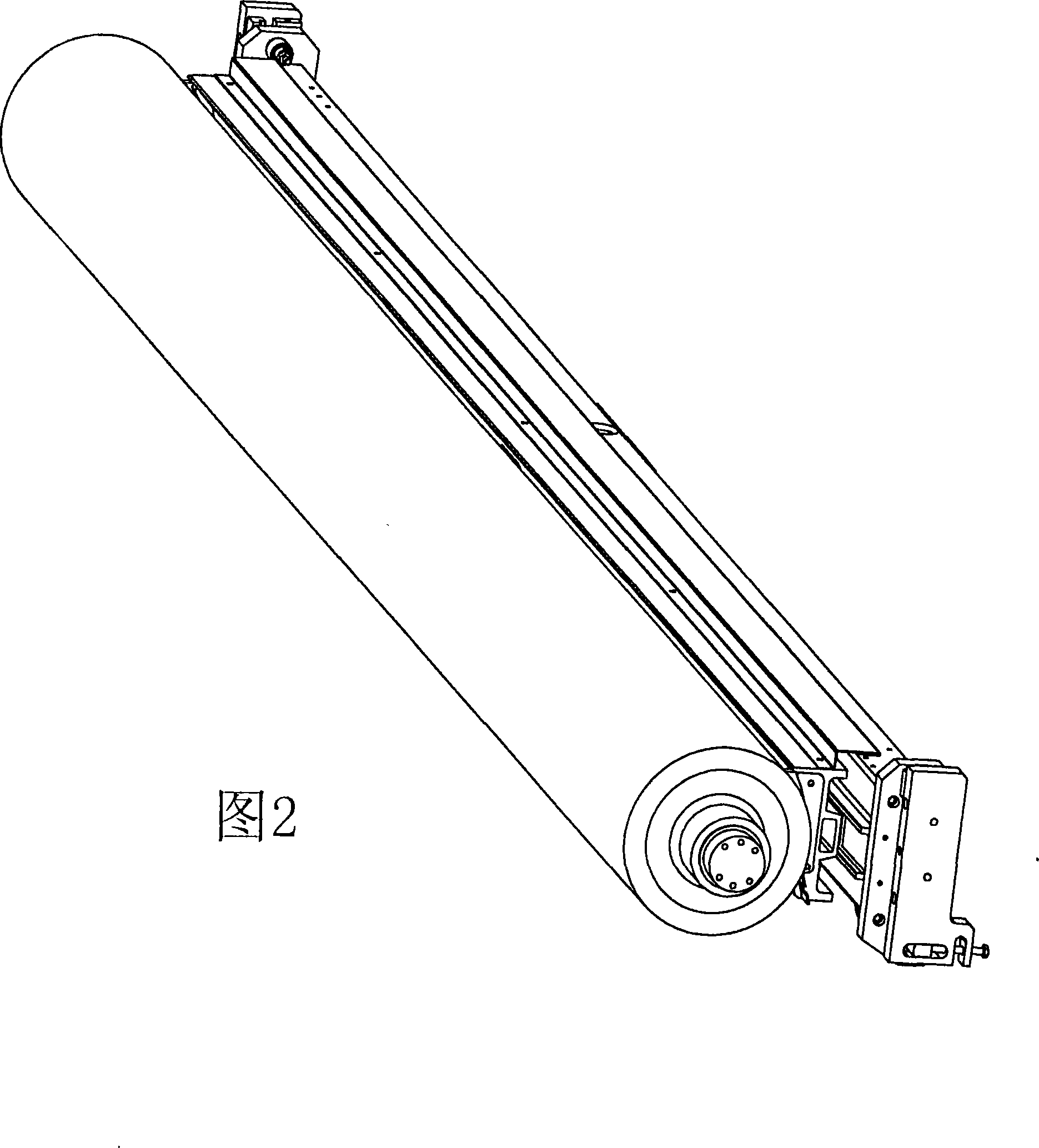

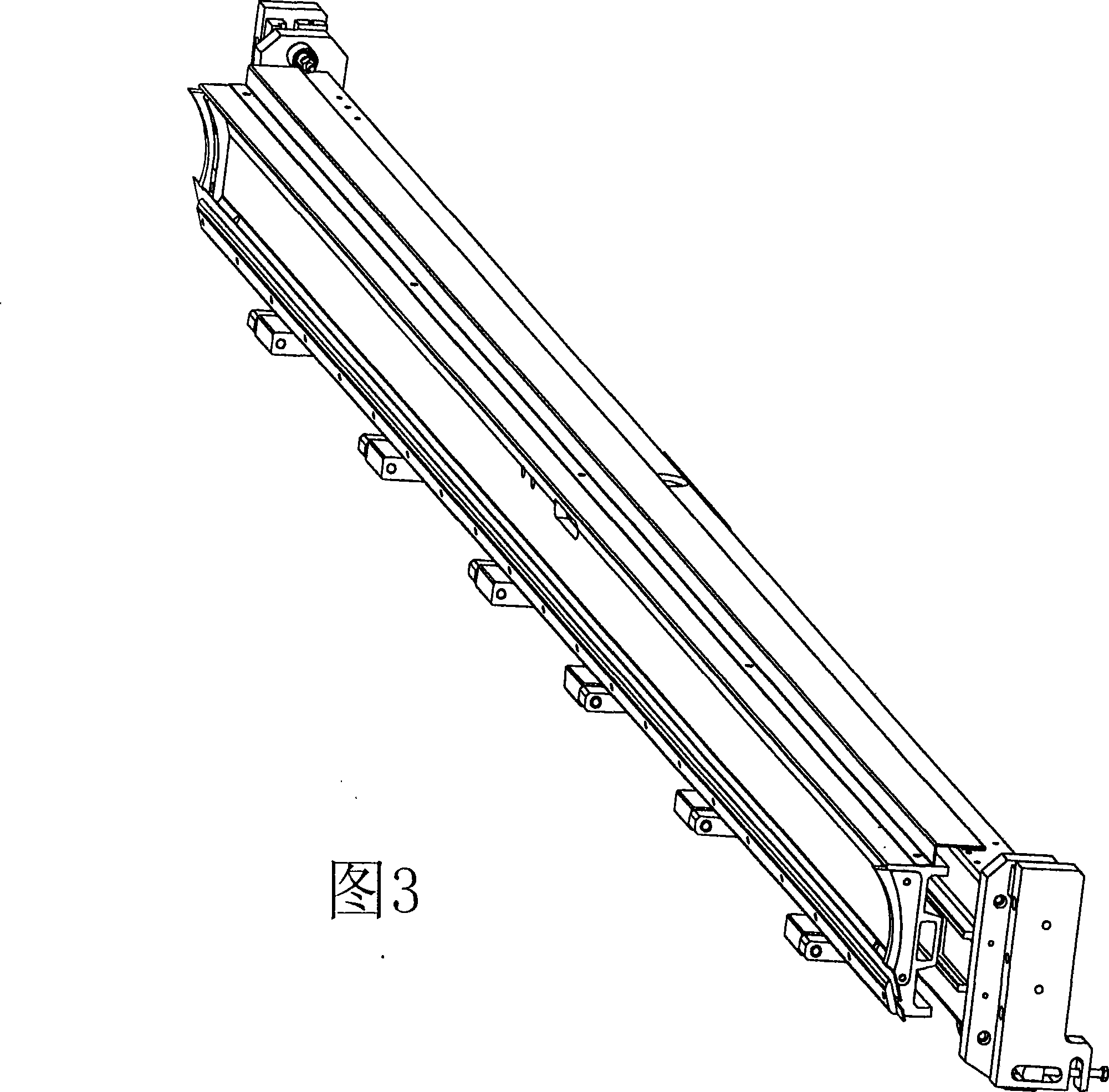

[0009] As shown in Figures 1-3, this embodiment includes an anilox roller 1, a nylon end seal 2, an elastic end seal 3, a single scraper ink chamber 4, a spring stopper 5, a spring 6, and a spring rod 7 , air bag 9, scraper 10, gasket 11, pressure plate 12, hinge mechanism 13, screw 14, single scraper ink chamber 4 is installed on the support 8 by hinge mechanism 13, single scraper ink chamber 4 can rotate around the axis of hinge mechanism 13, The scraper 10 and the spacer 11 are fixed on the single scraper ink chamber 4 through the pressure plate 12 and the screw 11; the spring stopper 5 is fixed on the support 8, one end of the spring pull rod 7 is threaded, and the other end of the spring pull rod 7 is a disc-shaped shaft Shoulder, the threaded end of the spring pull rod 7 is installed in the screw hole of the single scraper ink chamber 4, and the spring 6 is installed between the spring stopper 5 and the disc-shaped shoulder of the spring pull rod 7; the nylon end sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com