Environment protection type reactive dye color fixing liquid alkali

A technology of reactive dyes and liquid alkali, applied in the field of reactive dyes, can solve the problems of interfering with dyeing of reactive dyes, lowering the color yield of fabrics, lowering the solubility of dyes, etc., achieving good washability, good levelness and reducing alkali content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-6

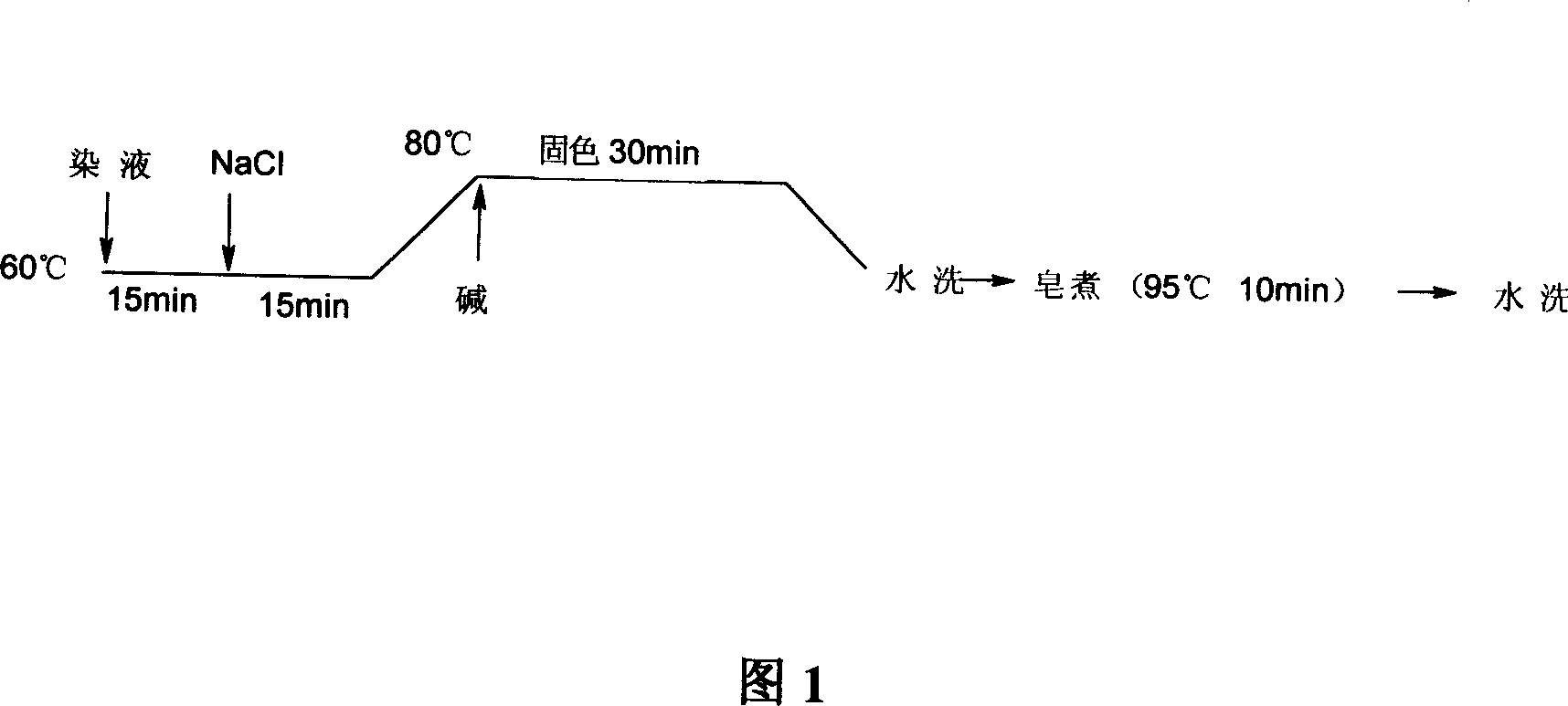

[0045] Select reactive dye M-3BFN red, concentration 2% (o.w.f), sodium chloride 40g / L, liquid alkali 2.0g / L, sodium carbonate 15g / L, technological process as shown in Figure 1, the results are shown in Table 1:

[0046] Table 1

[0047] example

example 7-12

[0049] Select reactive dye M-3RS yellow, concentration 2% (o.w.f), sodium chloride 40g / L, liquid alkali 2.0g / L, sodium carbonate 15g / L, technological process as shown in Figure 1, the results are shown in Table 2:

[0050] Table 2

[0051] example

example 13-18

[0053] Select reactive dye M-BES brilliant blue, concentration 2% (o.w.f), sodium chloride 40g / L, liquid alkali 2.0g / L, sodium carbonate 15g / L, technological process as shown in Figure 1, the results are shown in Table 3:

[0054] table 3

[0055] example

son

Liquid Color Fixing Base

stained with soda ash

whether

suitable

Preface

No

NaOH

(x%

)

KOH

(y%)

Na 2 CO 3

(z%)

K 2 CO 3

(m%)

stabilizer

(n%)

Chelating agent

(p%)

water

(%)

13

2.5

2.5

17.5

17.5

5.1

0.11

54.79

-2.5%

yes

14

5

5

15

15

5.1

0.11

54.79

+0.67%

yes

15

7.5

7.5

12.5

12.5

5.1

0.11

54.79

+3.05%

yes

16

10

10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com