Device for on-line cleaning of selective catalyctic reduction (SCR) denitration catalyst and cleaning process thereof

A denitrification catalyst and process technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increasing the catalyst cleaning cycle, unfavorable operating costs of enterprises, and a large number of engineering personnel, etc., to achieve cleaning The process is simple and reliable, saves manpower and material resources, and improves the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

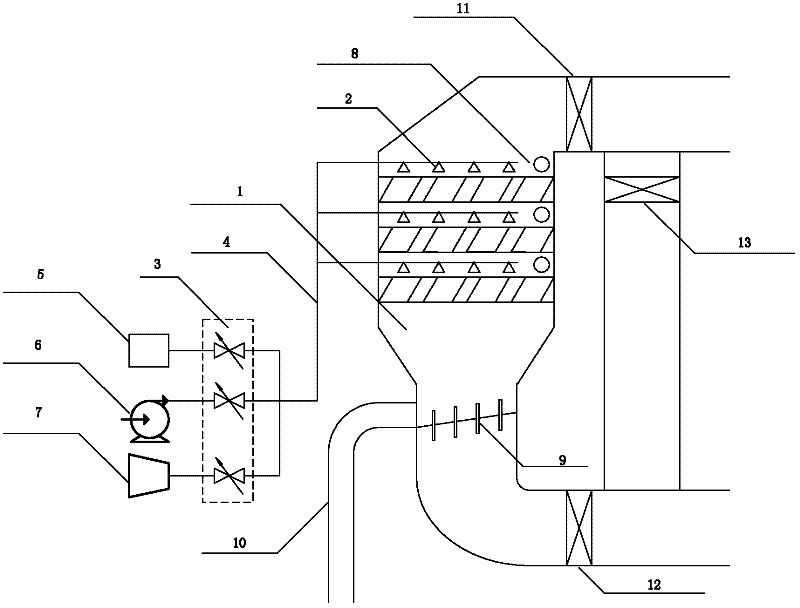

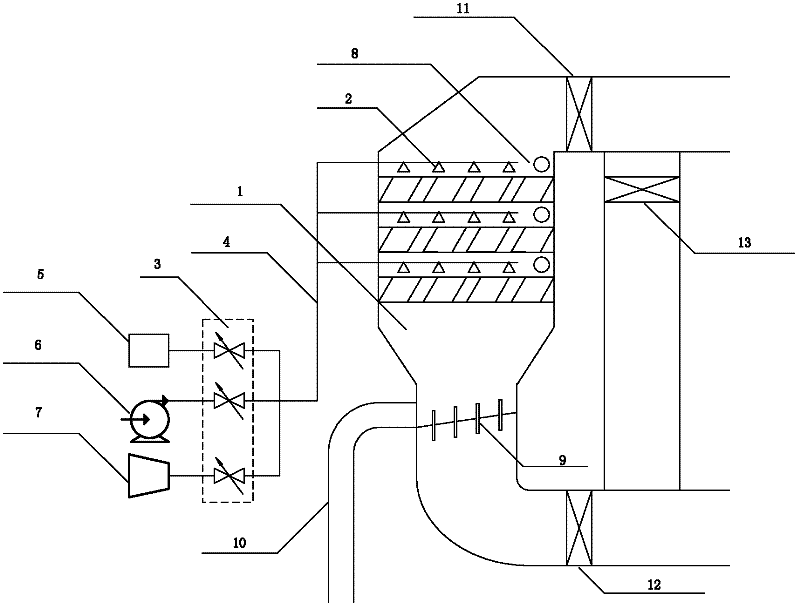

[0029] As shown in the attached figure, the device for online cleaning of SCR denitrification catalyst includes three groups of atomizing nozzles 2 arranged in SCR denitrification reactor 1, and the three groups of atomizing nozzles 2 are connected with steam The generator and controller 5, the cleaning liquid delivery pump 6 and the hot air delivery fan 7 are connected together. In addition, each group of atomization nozzles 2 is equipped with a group of sonic soot blowers 8, and the three groups of atomizers in the SCR denitrification reactor 1 A waste liquid deflector 9 is arranged under the nozzle 2, and the waste liquid deflector 9 is connected with the waste liquid collection pipe 10 provided on the outer wall of the SCR denitrification reactor 1. The inlet and outlet of the SCR denitrification reactor 1 And the bypass is respectively provided with a reactor inlet baffle 11, a reactor outlet baffle 12 and a reactor bypass baffle 13, wherein the steam generation and contro...

Embodiment 2

[0039] As shown in the attached figure, the device for online cleaning of SCR denitrification catalyst includes three groups of atomizing nozzles 2 arranged in SCR denitrification reactor 1, and the three groups of atomizing nozzles 2 are connected with steam The generator and controller 5, the cleaning liquid delivery pump 6 and the hot air delivery fan 7 are connected together. In addition, each group of atomization nozzles 2 is equipped with a group of sonic soot blowers 8, and the three groups of atomizers in the SCR denitrification reactor 1 A waste liquid deflector 9 is arranged under the nozzle 2, and the waste liquid deflector 9 is connected with the waste liquid collection pipe 10 provided on the outer wall of the SCR denitrification reactor 1. The inlet and outlet of the SCR denitrification reactor 1 And the bypass is respectively provided with a reactor inlet baffle 11, a reactor outlet baffle 12 and a reactor bypass baffle 13, wherein the steam generation and contro...

Embodiment 3

[0049] As shown in the attached figure, the device for online cleaning of SCR denitrification catalyst includes three groups of atomizing nozzles 2 arranged in SCR denitrification reactor 1, and the three groups of atomizing nozzles 2 are connected with steam The generator and controller 5, the cleaning liquid delivery pump 6 and the hot air delivery fan 7 are connected together. In addition, each group of atomization nozzles 2 is equipped with a group of sonic soot blowers 8, and the three groups of atomizers in the SCR denitrification reactor 1 A waste liquid deflector 9 is arranged under the nozzle 2, and the waste liquid deflector 9 is connected with the waste liquid collection pipe 10 provided on the outer wall of the SCR denitrification reactor 1. The inlet and outlet of the SCR denitrification reactor 1 And the bypass is respectively provided with a reactor inlet baffle 11, a reactor outlet baffle 12 and a reactor bypass baffle 13, wherein the steam generation and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com