Water-saving high pressure water workpiece washing line

A high-pressure water, cleaning line technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems that cleaning, rinsing and anti-rust treatment cannot be completed in one step, and work efficiency needs to be improved. , to achieve the effect of good cleaning effect, clean working process and saving cleaning water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

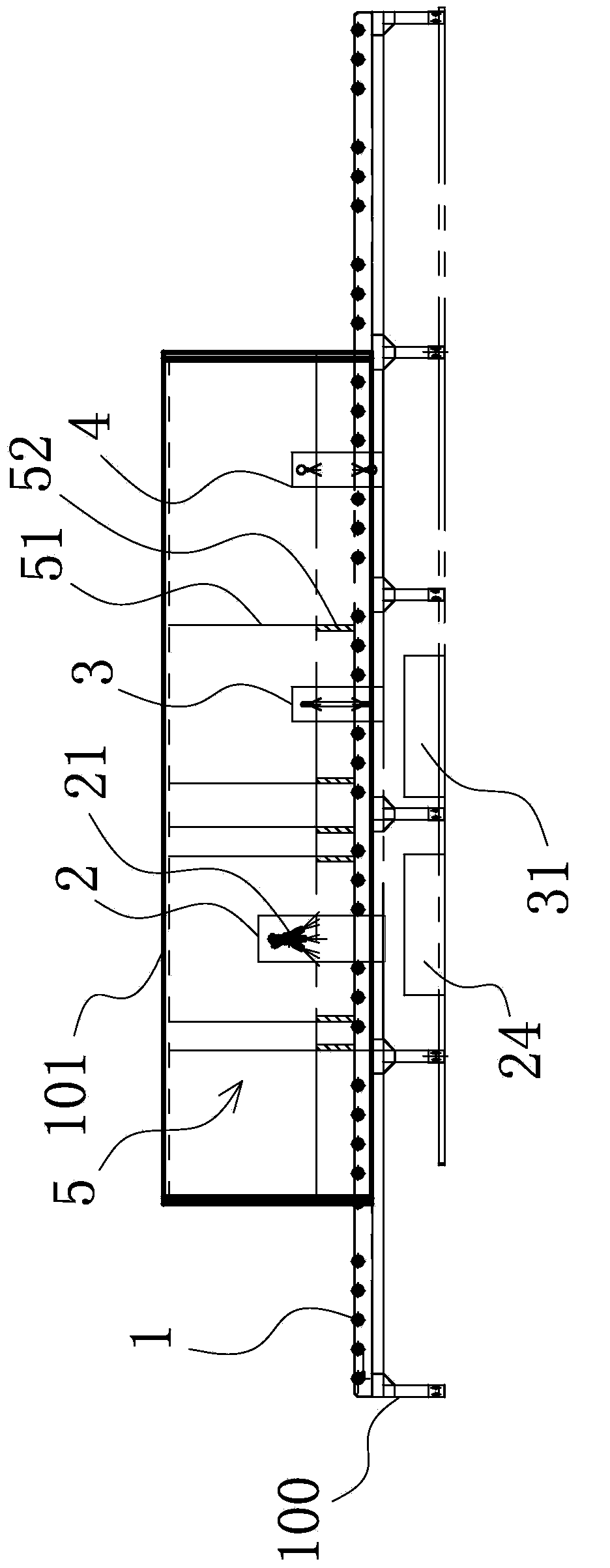

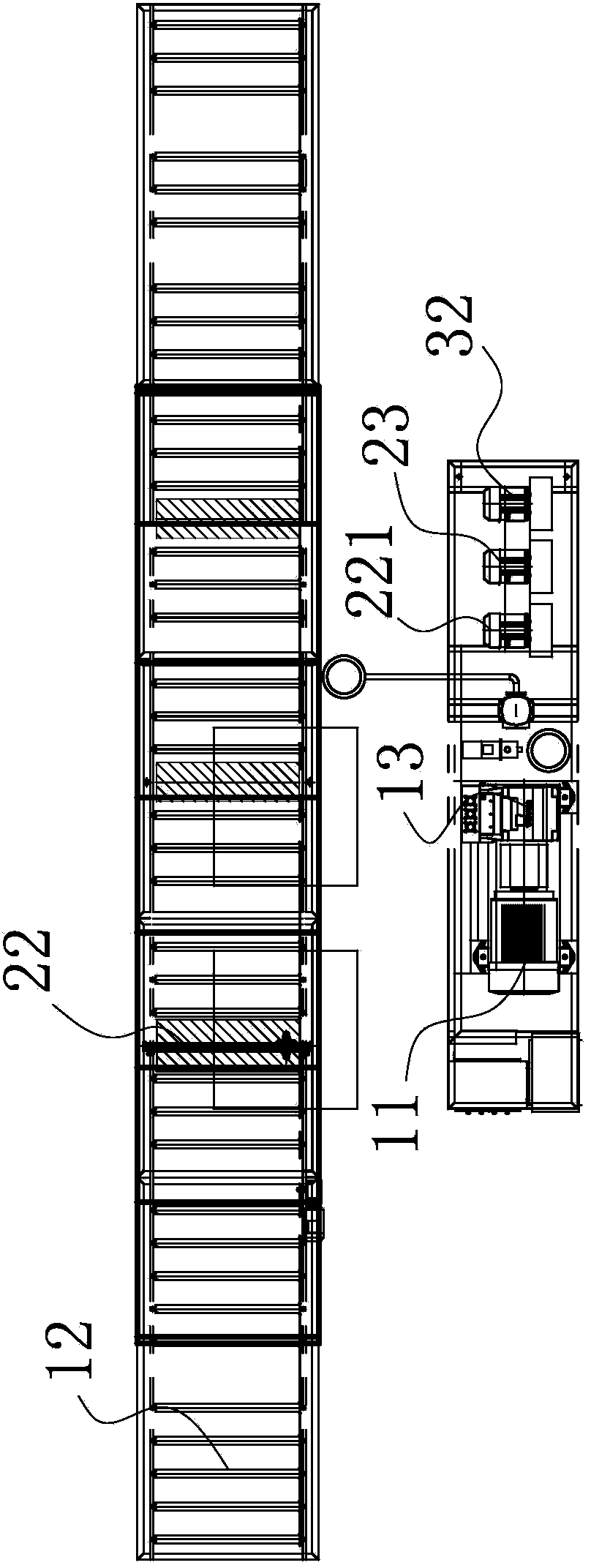

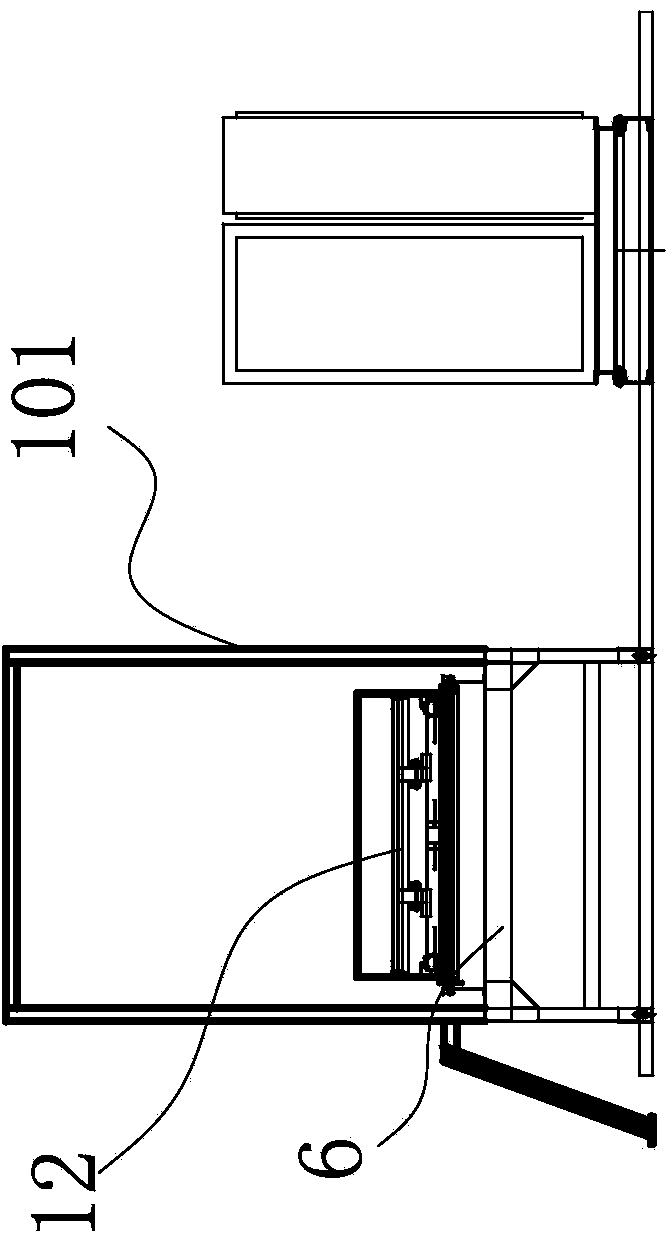

[0022] Such as Figure 1-6 As shown, a water-saving high-pressure water workpiece cleaning line includes a machine base 100, the machine base 100 is provided with a chassis 101, and the machine base 100 is provided with a pulley conveying mechanism 1 inside the chassis 101 , the pulley conveying mechanism 1 can be a roller pulley or a chain pulley, and the pulley conveying mechanism 1 plays the role of conveying workpieces; a high-pressure water spray mechanism 2 is also provided in the cabinet 101, and the high-pressure water The spray mechanism 2 includes a high-pressure water nozzle 21 capable of spraying high-pressure water and a nozzle driving mechanism 22 capable of driving the high-pressure water nozzle 21 to reciprocate. To save water and improve the cleaning effect, the high-pressure water spray head 21 is located above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com