Environmentally-friendly and long-lasting fire-retarding treatment method for all-cotton knitted fabrics

A durable flame retardant and flame retardant finishing technology, applied in fiber processing, textiles and papermaking, plant fibers, etc., can solve the problems of high free and released formaldehyde content, irritating odor, complicated equipment, etc., to achieve low content, in line with environmental protection Requirement, soft-touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

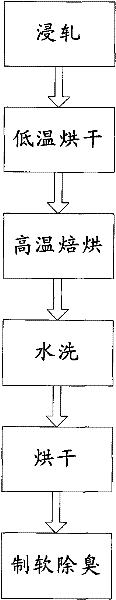

Method used

Image

Examples

Embodiment 1

[0055] (1), Padding:

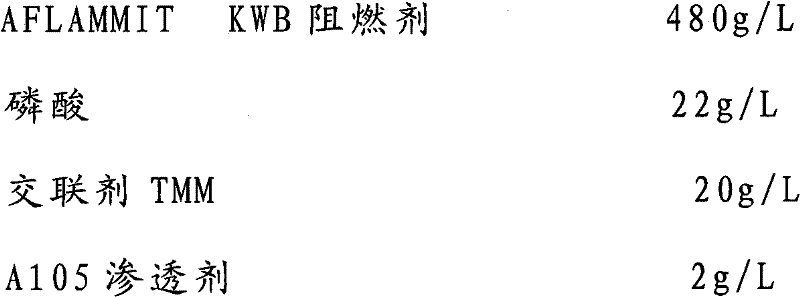

[0056] First prepare the flame retardant finishing liquid, in which:

[0057] AFLAMMIT KWB Flame Retardant 480g / L

[0058] Phosphoric acid 22g / L

[0059] Cross-linking agent TMM 20g / L

[0060] A105 Penetrant 2g / L

[0061] Secondly, the cotton reactive printed knitted fabric is dipped in the flame-retardant finishing solution, one dip and one roll, the roll pressure is 0.22MPa, and the excess rate is 100%;

[0062] (2) Low-temperature drying: control the temperature at 100-120°C and control the speed at 9y / min for drying, subject to thorough drying;

[0063] (3) High-temperature baking: bake at 160°C for 2 minutes;

[0064](4) Water washing: wash with cold water first, then wash with alkali at 50°C for 10 minutes, then wash with water at 70°C for 10 minutes, then wash with 1.5mL / L 27.5% hydrogen peroxide at 40°C for 10 minutes, and finally wash with cold water;

[0065] (5), drying: drying the finished cloth;

[0066] (6), softening and deodorizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com