A method and water curtain cabinet for treating spraying exhaust gas

A technology for waste gas and water curtain, applied in the method and water curtain cabinet, in the field of treatment of spraying waste gas, can solve the problems of the purification treatment system not running normally, affecting the effect of waste gas treatment, waterway and airway blockage, etc., so as to improve the effect of paint mist removal. , Conducive to mass transfer efficiency and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

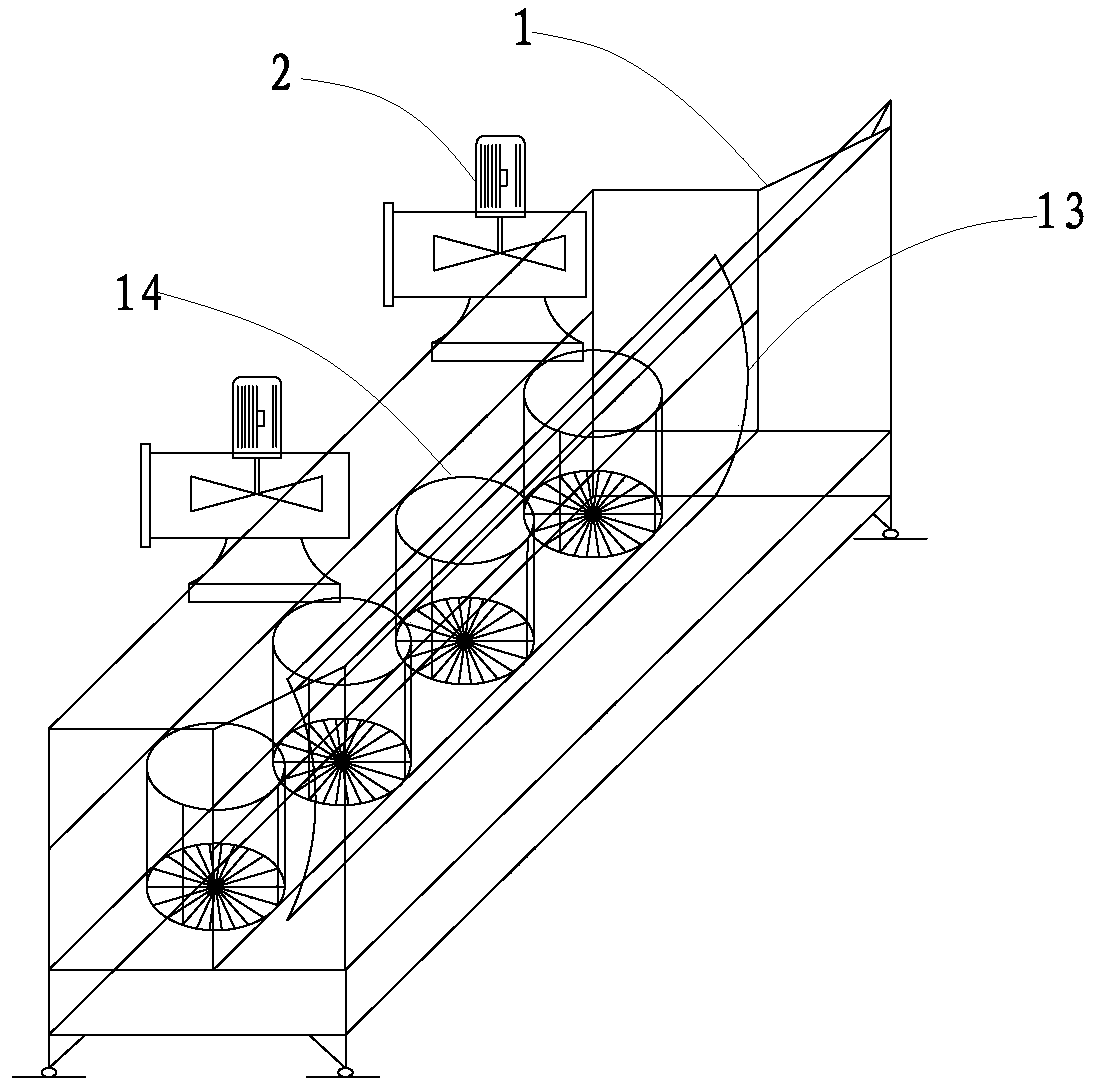

[0054] A method for treating spraying exhaust gas, comprising the steps of:

[0055] Exhaust gas is sucked in: suction device 2 sucks the spraying exhaust gas that spraying process produces into exhaust gas treatment chamber;

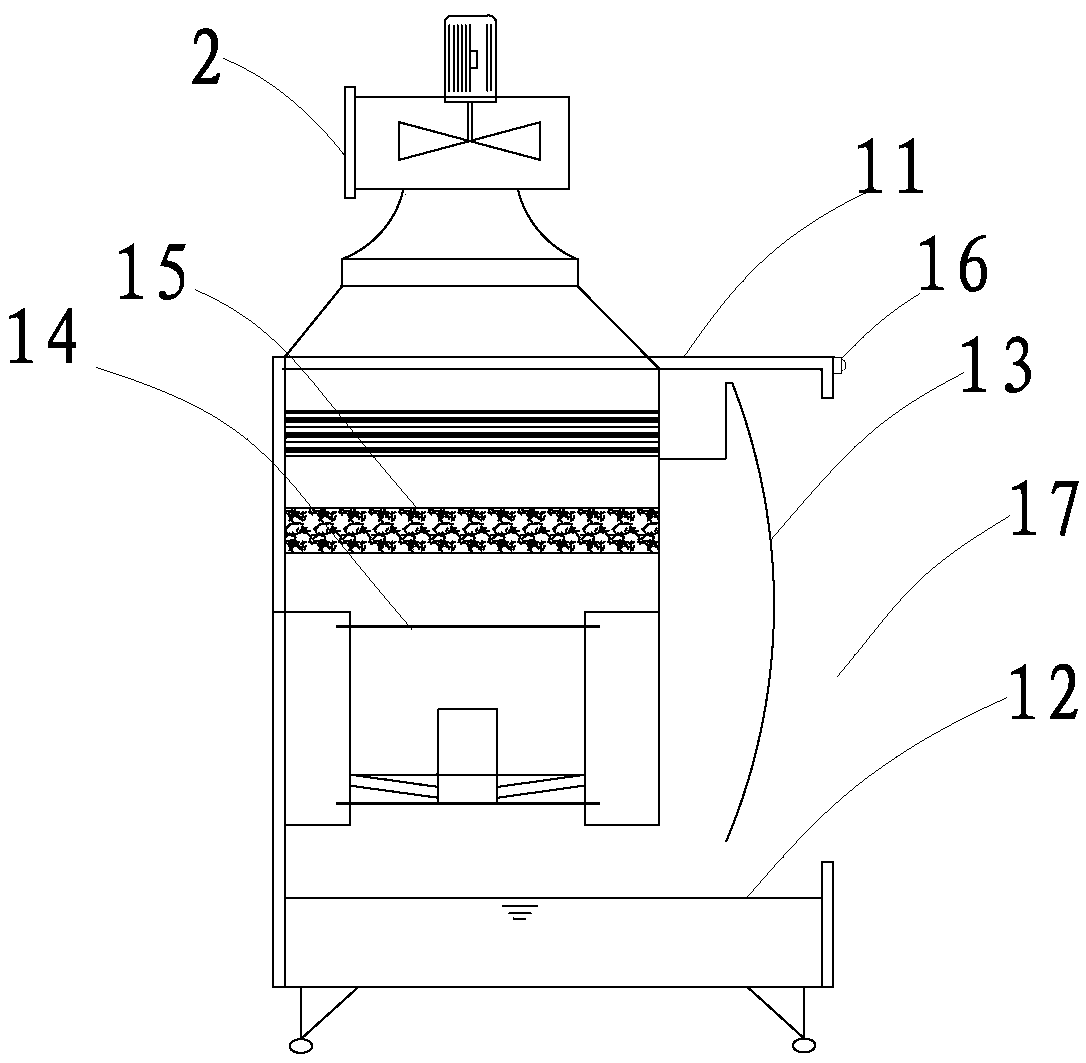

[0056] Water curtain absorption: the circulating water forms a water curtain on the water curtain baffle 13, and the water curtain showers and absorbs the spraying exhaust gas entering the exhaust gas treatment chamber, and the circulating water is added with paint mist decomposition agents and paint mist capture agents;

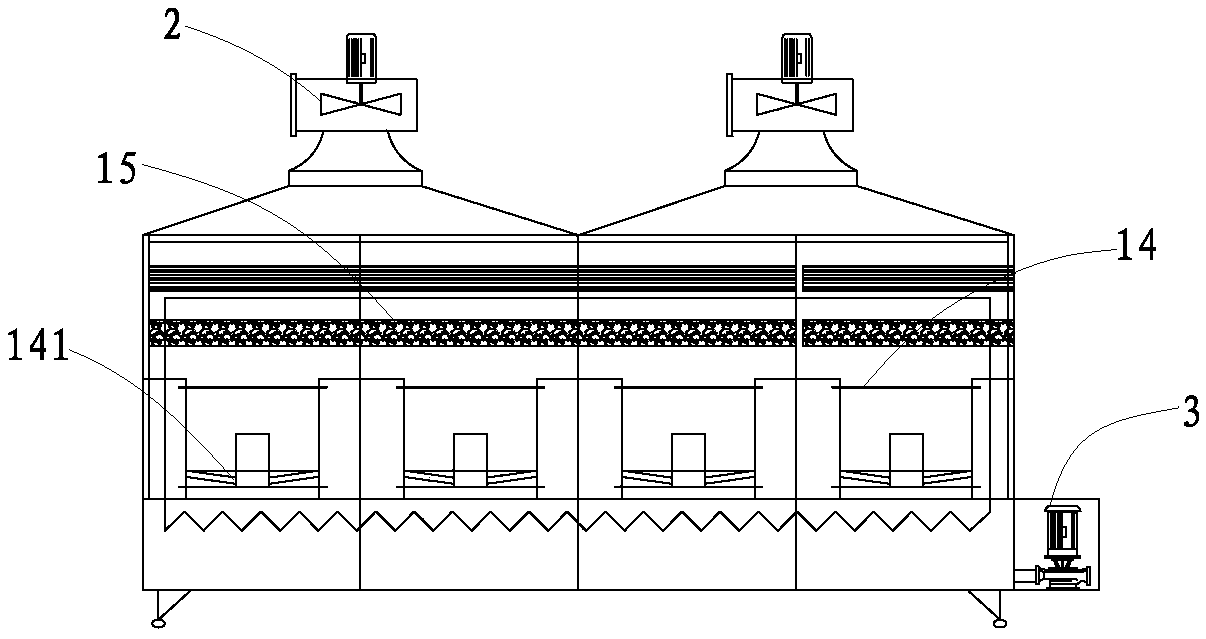

[0057] Swirling water washing: The paint mist in the spraying exhaust gas is brought into the circulating pool 12 by the water curtain, and part of the spraying exhaust gas enters the swirling device 14 to be washed by swirling water;

[0058] Demisting absorption: the sprayed gas-liquid mixture after being sprayed and absorbed is treated by the demisting layer 15;

[0059] Exhaust gas extraction: the spraying exhaust gas treated by ...

Embodiment 2

[0080] The difference between this embodiment and embodiment 1 is:

[0081] In this embodiment, the paint mist decomposition agent includes the following components in mass percentage:

[0082] Active foaming agent 15%

[0084] Citric acid 5%

[0085] water balance.

[0086] Further, the active foaming agent is dodecyl dimethyl hydroxypropyl phospholipid betaine.

[0087] Further, the paint mist trapping agent includes anionic polyacrylamide with a mass concentration of 10%. The molecular weight of the anionic polyacrylamide is 3 million.

[0088] Further, the paint mist trapping agent also includes lignin with a mass fraction of 10% and nano-alumina with a mass fraction of 20%, and the particle size of the nano-alumina is 30nm.

[0089] Further, the defogging layer 15 is provided with Pall ring fillers. Further, the defogging layer 15 includes two layers of defogging layers 15, which enhances the defogging effect.

[0090] Further, there a...

Embodiment 3

[0093] The difference between this embodiment and embodiment 1 is:

[0094] In this embodiment, the paint mist decomposition agent includes the following components in mass percentage:

[0095] Active foaming agent 25%

[0097] Citric acid 10%

[0098] water balance.

[0099] Further, the active foaming agent is fatty alcohol polyoxyethylene ether.

[0100] Further, the paint mist trapping agent includes anionic polyacrylamide with a mass concentration of 60%. The molecular weight of the anionic polyacrylamide is 10 million.

[0101] Further, the paint mist trapping agent also includes 30% lignin by mass fraction and 10% nano-alumina, and the particle size of the nano-alumina is 80nm.

[0102] Further, the demister layer 15 is provided with stepped ring packing. Further, the defogging layer 15 includes two layers of defogging layers 15, which enhances the defogging effect.

[0103] Further, there are two cyclone devices 14 . Using a plural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com