Antibacterial waterborne polyurethane and a synthetic method thereof

A technology of water-based polyurethane and antibacterial activity is applied in the field of preparation of water-based polyurethane to achieve the effects of low price, good antibacterial effect and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

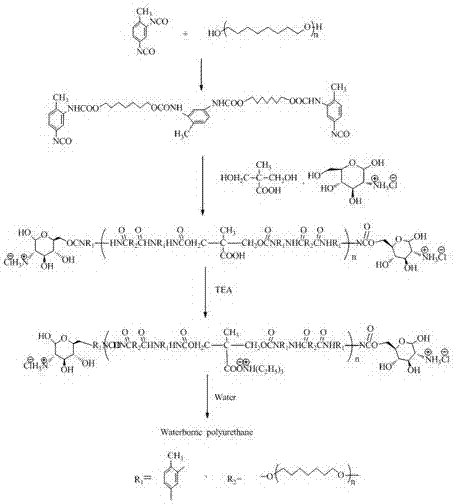

Image

Examples

Embodiment 1

[0022] Add 250g of polyoctamethylene glycol adipate into a 1500ml flask, add 150g of butanone, add 108.8g of toluene diisocyanate at 50°C, and stir for 3 hours. 2.5 g of D-glucosamine hydrochloride was added, and the mixture was stirred and reacted at 70° C. for 2 hours. 7.5g of 2,2-dimethylolpropionic acid was added, and the mixture was stirred and reacted at 70°C for 3 hours. The reaction liquid was cooled to 45° C., a certain amount of triethylamine was added, and the mixture was kept stirring for 1 hour. A certain amount of deionized water was added, and emulsified for 1 hour under mechanical stirring to obtain a polyurethane emulsion.

Embodiment 2

[0024] Add 200g of polyoxyethylene diol into a 1500ml flask, add 150g of butanone, add 120g of diphenylmethane diisocyanate at 60°C, and stir for 3 hours. Add 4.7g of D-glucosamine hydrochloride, and keep stirring at 80°C for 2 hours. 18g of 2,2-dimethylolpropionic acid was added, and the mixture was stirred and reacted at 80°C for 3 hours. The reaction solution was cooled to 30° C., a certain amount of triethylamine was added, and the mixture was kept stirring for 1 hour. A certain amount of deionized water was added, and emulsified for 1 hour under mechanical stirring to obtain a polyurethane emulsion.

Embodiment 3

[0026] Add 230g of polyoxypropylene diol into a 1500ml flask, add 150g of butanone, add 110g of xylylene diisocyanate at 70°C, and stir for 3 hours. 11 g of D-glucosamine hydrochloride was added, and the mixture was stirred and reacted at 80° C. for 2 hours. 20g of 2,2-dimethylolpropionic acid was added, and the mixture was stirred and reacted at 80°C for 3 hours. The reaction liquid was cooled to 50° C., a certain amount of triethylamine was added, and the mixture was kept stirring for 1 hour. A certain amount of deionized water was added, and emulsified for 1 hour under mechanical stirring to obtain a polyurethane emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com