Oscillating arm type strong grinding mill

A pulverizer and swing-arm technology, applied in the field of swing-arm powerful pulverizers, can solve the problems of pulling one hair and moving the whole body, and achieve the effect of increasing the grinding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

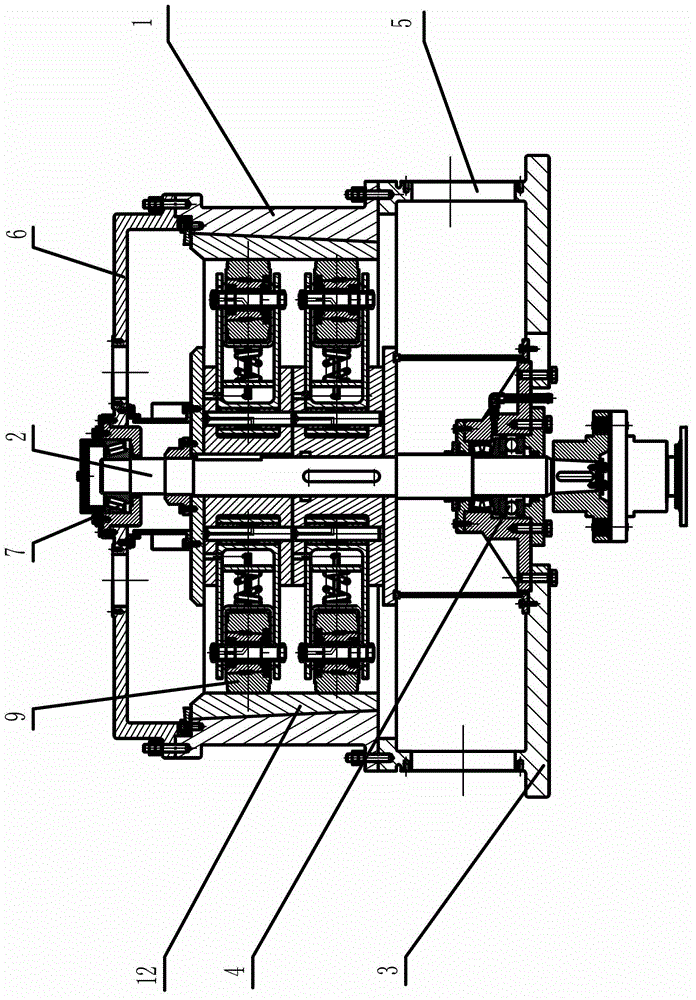

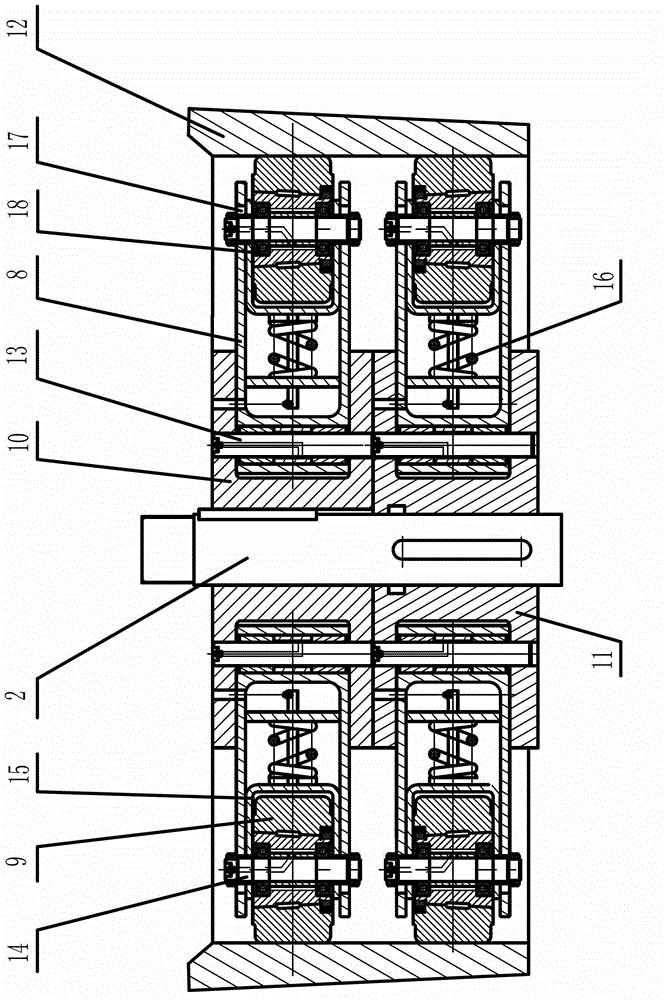

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0021] The swing arm type powerful mill of the present invention takes the ring roller mill as an example, and its milling host includes a host shell 1, a host upper cover 6, a host base 3, a main shaft 2, a grinding roller device and a grinding ring 12, and the host shell 1 The upper and lower openings of the main engine are respectively connected and installed with the main engine upper cover 6 and the main engine base 3 through flanges. The main engine main shaft 2 is vertically placed on the central axis of the main engine shell 1. The bearing positions 7 and 4 are respectively supported and installed, and the upper and lower bearing positions 7 and 4 are respectively arranged at the center of the upper cover 6 of the main machine and the base 3 of the main machine. The outer conical surface of the grinding ring 12 is fixedly installed after coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com