Direct Drive Primary Structures for Roller Mills

A direct-drive main and roller mill technology, applied in grain processing, etc., can solve the problems of reducing the rated output of the roller mill, the length of the power transmission chain, and the poor rigidity of the pendulum G, so as to reduce the transmission chain components and improve the milling efficiency. Effect of pressure, increased rigidity and smooth running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

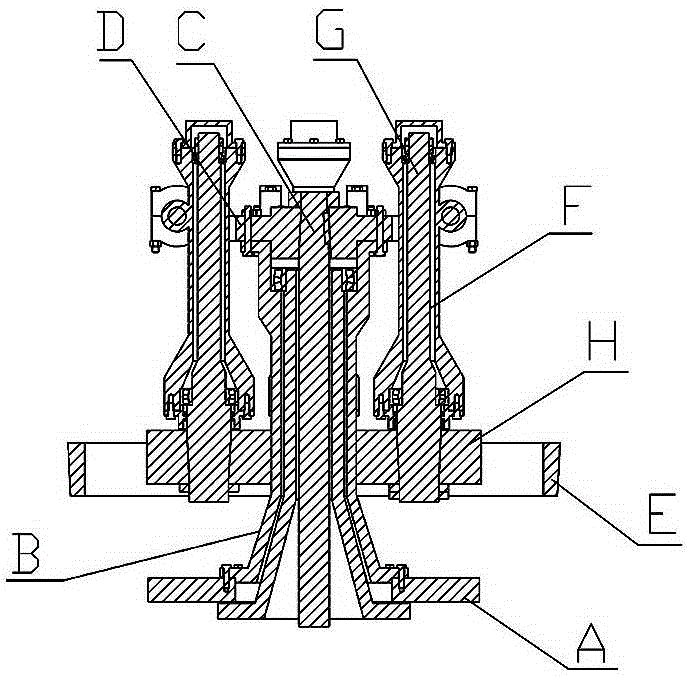

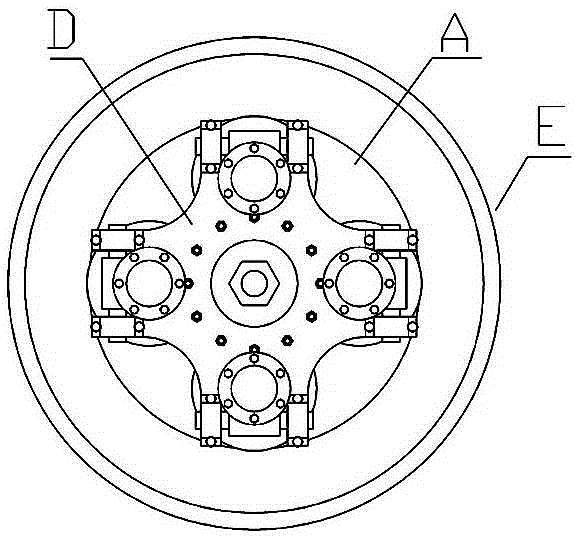

[0021] like Figure 3-1 , Figure 2-2 As shown, the direct-drive main structure for the roller mill of the present invention includes a blade base plate 1, a grinding ring 2 fixed on the base of the roll mill around the blade base plate 1, and the The grinding roller 3 rolling on the inner ring surface of the grinding ring 2 and the power input shaft 4 driven by the motor; the power input shaft 4 is vertically fixed on the middle part of the lower surface of the shovel seat plate 1 or connected with the shovel through a transmission part The lower plate surface of the base plate 1 is connected by transmission; the grinding roller 3 is arranged on the upper plate surface of the blade base plate 1 through a transmission mechanism; The pin shaft 5 is hinged to the horizontal swing rod 6 , and the roller shaft 7 of the grinding roller 3 is fixed vertically upward on the other end of the horizontal swing rod 6 .

Embodiment 2

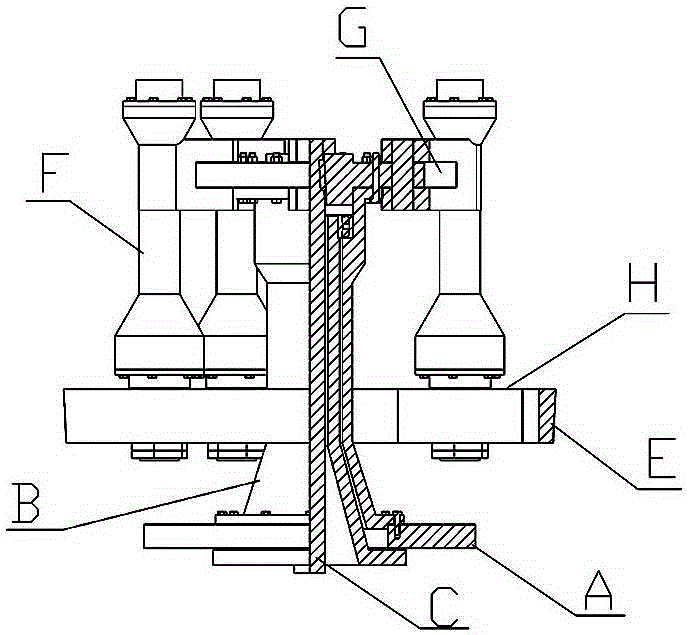

[0023] like Pic 4-1 , Figure 4-2 As shown, the direct-drive main structure for the roller mill of the present invention includes a blade base plate 1, a grinding ring 2 fixed on the base of the roll mill around the blade base plate 1, and the The two grinding rollers 3 rolling on the inner ring surface of the grinding ring 2 and the power input shaft 4 driven by the motor; the power input shaft 4 is vertically fixed on the middle part of the lower plate surface of the shovel holder plate 1 or connected with the The lower plate surface of the shovel seat plate 1 is connected by transmission; the two grinding rollers 3 are respectively arranged on the upper plate surface of the shovel knife seat plate 1 through a transmission mechanism; the transmission mechanism is vertically fixed on the upper plate surface of the shovel knife seat plate 1 The support bar 8 and the horizontal hanger 9 fixed on its top; the two grinding rollers 3 are arranged vertically downward symmetricall...

Embodiment 3

[0025] like Figure 5-1 , Figure 5-2 As shown, the direct-drive main structure for the roller mill of the present invention includes a blade base plate 1, a grinding ring 2 fixed on the base of the roll mill around the blade base plate 1, and the The grinding roller 3 rolling on the inner ring surface of the grinding ring 2 and the power input shaft 4 driven by the electric motor; The inner guide rail 12, the roller shaft 7 of the grinding roller 3 is fixed vertically upward on the end of the guide rail 12 extending out of the horizontal chute 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com