A kind of flame-retardant antistatic thermoplastic polyurethane elastomer and its preparation method and application

A thermoplastic polyurethane, flame retardant and antistatic technology, applied in the field of polymer materials, can solve the problems of product strength reduction, high production cost, complicated process, etc., and achieve excellent flame retardancy, avoid impact, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Mix 10kg tricresyl phosphate (TCP), 10kg sodium dodecylbenzenesulfonate, 0.5kg tetrakis (4-hydroxy 3,5-tert-butylphenyl propionate) pentaerythritol ester and 10kg dipropylene glycol diphenyl Add the formic acid ester into the high mixer, heat and stir for 1 hour, set the high temperature of the high mixer to 80°C, and set the stirring speed to 100r / min to obtain the modified mother liquor;

[0023] Step 2: Add 1000kg of thermoplastic polyurethane elastomer (mirathane E390C4) into a double-helix conical mixer, stir for 60min, and heat to 100°C;

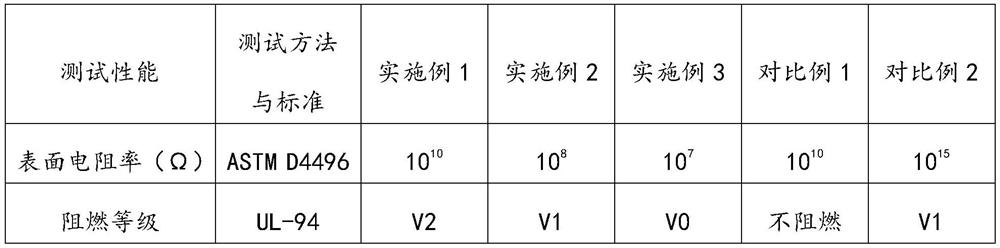

[0024] Step 3: Divide the modified mother liquor in step 1 into 5 times on average, and add it to the double-helix conical mixer in step 2 at an interval of 30 minutes each time. After all the modified mother liquor is added, continue to stir for 5 hours to obtain the resistance Flame antistatic thermoplastic polyurethane elastomer, the test results are shown in Table 1 below.

Embodiment 2

[0026] Step 1: 100kg tributyl phosphate (TBP), 50kg lithium trifluoromethanesulfonamide, 1kg tris (2.4-di-tert-butylphenyl) phosphite and 100kg diethylene glycol dibenzoate were added to the high In the mixer, heat and stir for 1 hour, set the heat preservation temperature of the high mixer to 80°C, and set the stirring speed to 100r / min to obtain the modified mother liquor;

[0027] Step 2: Add 1000kg of thermoplastic polyurethane elastomer (mirathane M85A1) into a double-helix conical mixer, stir for 60min, and heat to 80°C;

[0028] Step 3: Divide the modified mother liquor in step 1 on average 5 times, and add it to the double-helix conical mixer in step 2 at an interval of 30 minutes each time. After all the modified mother liquor is added, continue to stir for 5 hours to obtain a flame retardant The test results of antistatic thermoplastic polyurethane elastomer are shown in Table 1 below.

Embodiment 3

[0030] Step 1: 200kg tris(2-chloropropyl)phosphate (TCPP), 100kg2-naphthyl phosphate disodium salt, 2kg bis(3,5-di-tert-butyl-4-hydroxyphenylpropionic acid) and Add 200kg of diethylene glycol dibenzoate into the high mixer, heat and stir for 1 hour, set the temperature of the high mixer to 80°C, and set the stirring speed to 100r / min to obtain the modified mother liquor;

[0031] Step 2: Add 1000kg of thermoplastic polyurethane (mirathane E685C4) into a double-helix conical mixer, stir evenly, and heat to 120°C;

[0032] Step 3: Divide the modified mother liquor in step 1 on average 5 times, and add it to the double-helix conical mixer in step 2 at an interval of 30 minutes each time. After all the modified mother liquor is added, continue to stir for 5 hours to obtain a flame retardant The test results of antistatic thermoplastic polyurethane elastomer are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com