Insulating and heat-conducting polyamide composite material and preparation method thereof

A composite material, insulation and heat conduction technology, applied in the field of polyamide (PA) composite materials, can solve the problems of difficult processing and large filling volume, and achieve the effects of reducing water absorption, improving thermal conductivity, and increasing the degree of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

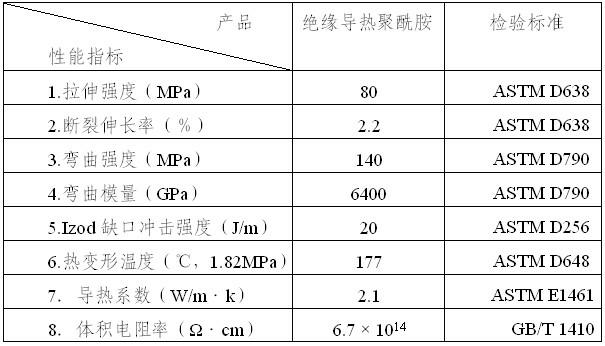

Embodiment 1

[0044] The raw material formula of following parts by weight

[0045] Polyamide (PA66) 80 parts

[0046] Polyphenylene sulfide (PPS) 20 parts

[0047] Flake Al 2 o 3 40 copies

[0048] Whisker Al 2 o 3 20 copies

[0049] Nano-AlN 2 parts

[0050] 10 parts glass fiber

[0051] 1.5 parts of silane coupling agent

[0052] Antioxidant 0.5 parts

[0053] Processing aid 1.0 parts

[0054] The glass fiber is pretreated with a silane coupling agent. Add flake and whisker Al in high speed mixer 2 o 3 , Nano-AlN, add silane coupling agent and then mix evenly at high speed, then add PA66, PPS, antioxidant, processing aid to mix evenly, add to twin-screw extruder, extrude and granulate at about 280°C, At the same time, pretreated glass fibers were added to obtain an insulating and heat-conducting polyamide composite material. The injection pressure was 10 MPa, the injection time was 30 seconds, and the mold temperature was...

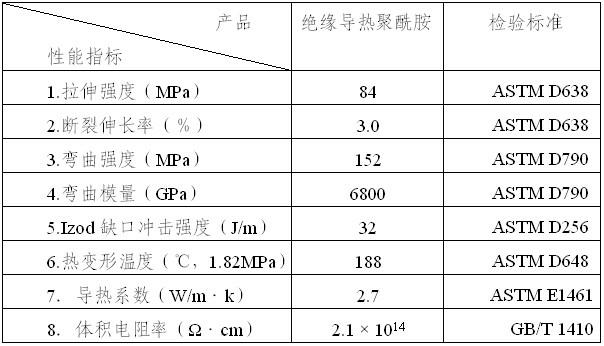

Embodiment 2

[0058] The raw material formula of following parts by weight

[0059] Polyamide (PA66) 70 parts

[0060] Polyphenylene sulfide (PPS) 30 parts

[0061]40 parts of flake Al powder

[0062] Whisker Al 2 o 3 20 copies

[0063] Nano-AlN 2.5 parts

[0064] 15 parts glass fiber

[0065] Silane coupling agent 2.0 parts

[0066] Antioxidant 0.5 parts

[0067] Processing aid 1.5 parts

[0068] The glass fiber is pretreated with a silane coupling agent. Add flake Al powder and whisker Al powder into the high-speed mixer 2 o 3 And nano-AlN, add silane coupling agent and mix evenly at high speed, then add PA66, PPS, antioxidant, processing aid to mix evenly, add to twin-screw extruder, extrude and granulate at about 280°C, At the same time, pretreated glass fibers were added to obtain an insulating and heat-conducting polyamide composite material. The injection pressure was 10 MPa, the injection time was 30 seconds, and the mold temperature was 100°C....

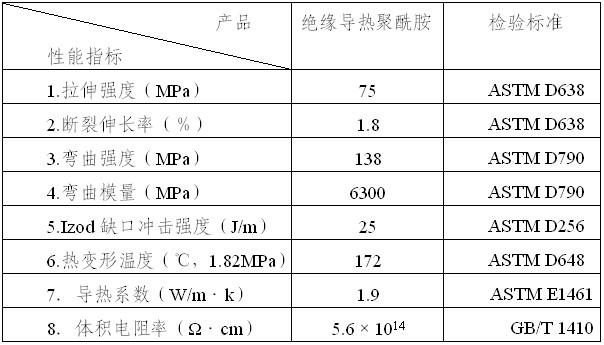

Embodiment 3

[0072] The raw material formula of following parts by weight

[0073] Polyamide (PA66) 60 parts

[0074] Polyphenylene sulfide (PPS) 40 parts

[0075] Flake Al 2 o 3 60 copies

[0076] Whisker MgO 10 parts

[0077] Nano-AlN 1.0 parts

[0078] 10 parts glass fiber

[0079] 1.5 parts of silane coupling agent

[0080] Antioxidant 0.5 part

[0081] Processing aid 1.0 parts

[0082] The glass fiber is pretreated with a silane coupling agent. Add flake Al in a high speed mixer 2 o 3 , whisker-like MgO, nano-AlN, add silane coupling agent and mix evenly at high speed, then add PA66, PPS, antioxidant, processing aid and mix evenly, then add it to the twin-screw extruder, at about 280 ° C Extrude and granulate, and add pretreated glass fibers at the same time to obtain an insulating and heat-conducting polyamide composite material. The injection pressure is 10 MPa, the injection time is 30 seconds, and the mold temperature is 100°C. Prepare sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com