A method for starting an integrated short-range nitrification-anammox process

A technology of anaerobic ammonium oxidation and short-range nitrification, which is applied in the field of start-up integrated short-range nitrification-anammox process, which can solve the problems of harsh operating conditions, unstable total nitrogen removal effect, slow start-up time, etc., and shorten the start-up time , avoid the generation of nitrification in the whole process, and accelerate the start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

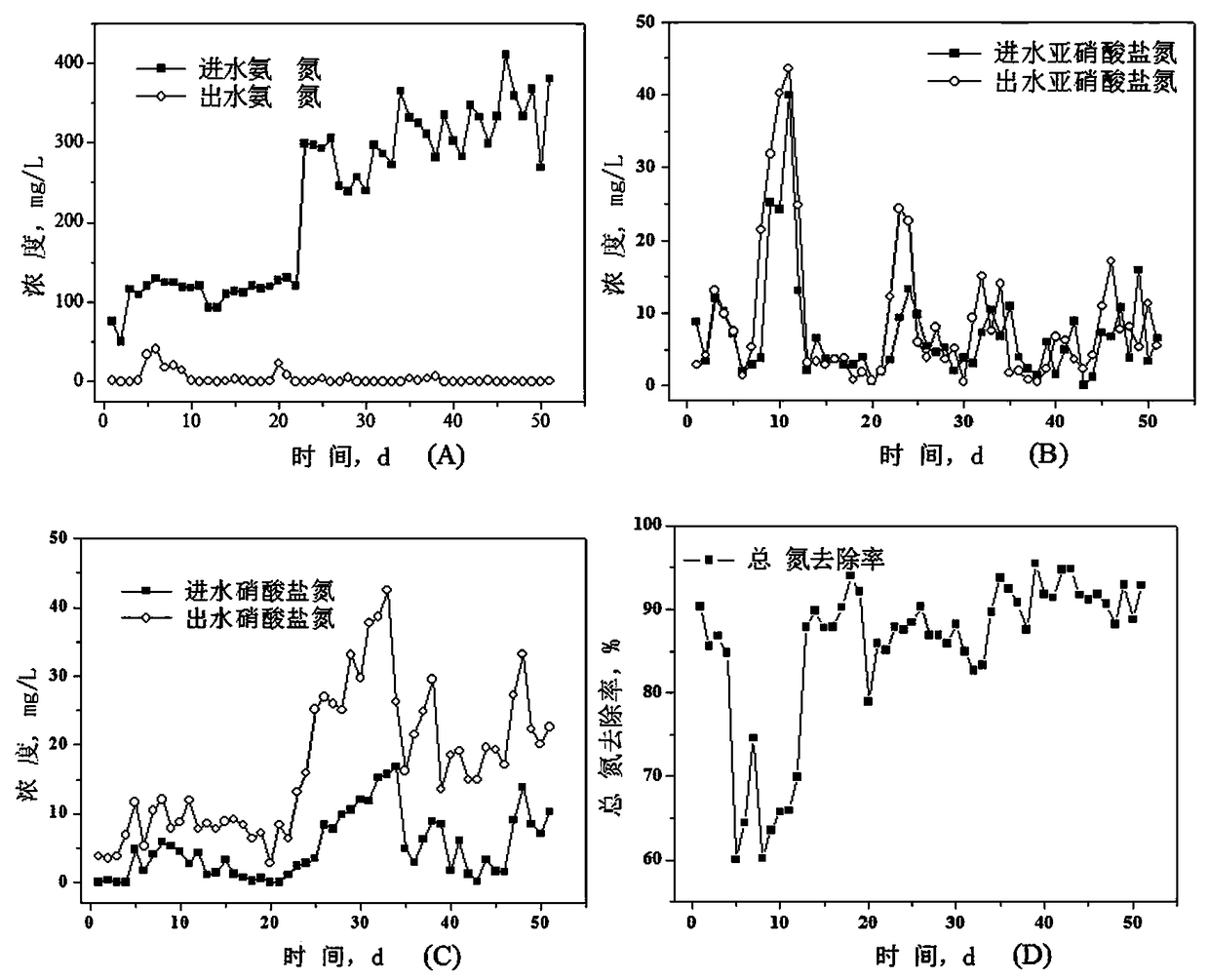

Embodiment 1

[0026] The short-course nitrification activated sludge cultivated in this laboratory was soaked in 2.5 mg / L NaCl solution for 24 hours in advance, and then the soaked short-course nitrification activated sludge and granular sludge (sludge with preliminary anaerobic ammonia oxidation activity) The mud color is red, and the total nitrogen volume removal load is 0.50 kgN / (m 3 · d)), inoculated according to the mass ratio of 4:5, and the MLSS was controlled at 5500 mg / L. The CANON reactor is made of plexiglass, the upper part is a cylinder, the bottom is a cone, the height is 400 mm, the diameter is 200 mm, and the effective volume is 10 L. Wrap the CANON reactor with aluminum foil tape to avoid light and keep warm, and control the temperature inside the CANON reactor to 30°C by heating in a water bath. The amount of aeration is controlled by a rotameter, and the DO is controlled below 0.5 mg / L. An operation cycle includes four stages of water intake, reaction, sedimentation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com