Lithium iron phosphate lithium battery cathode material

A technology of lithium iron phosphate and positive electrode material, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of hindering the vigorous promotion of lithium iron phosphate, poor conductivity, low packing density, etc., to increase mutual contact and conductivity. Strong, bulk density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

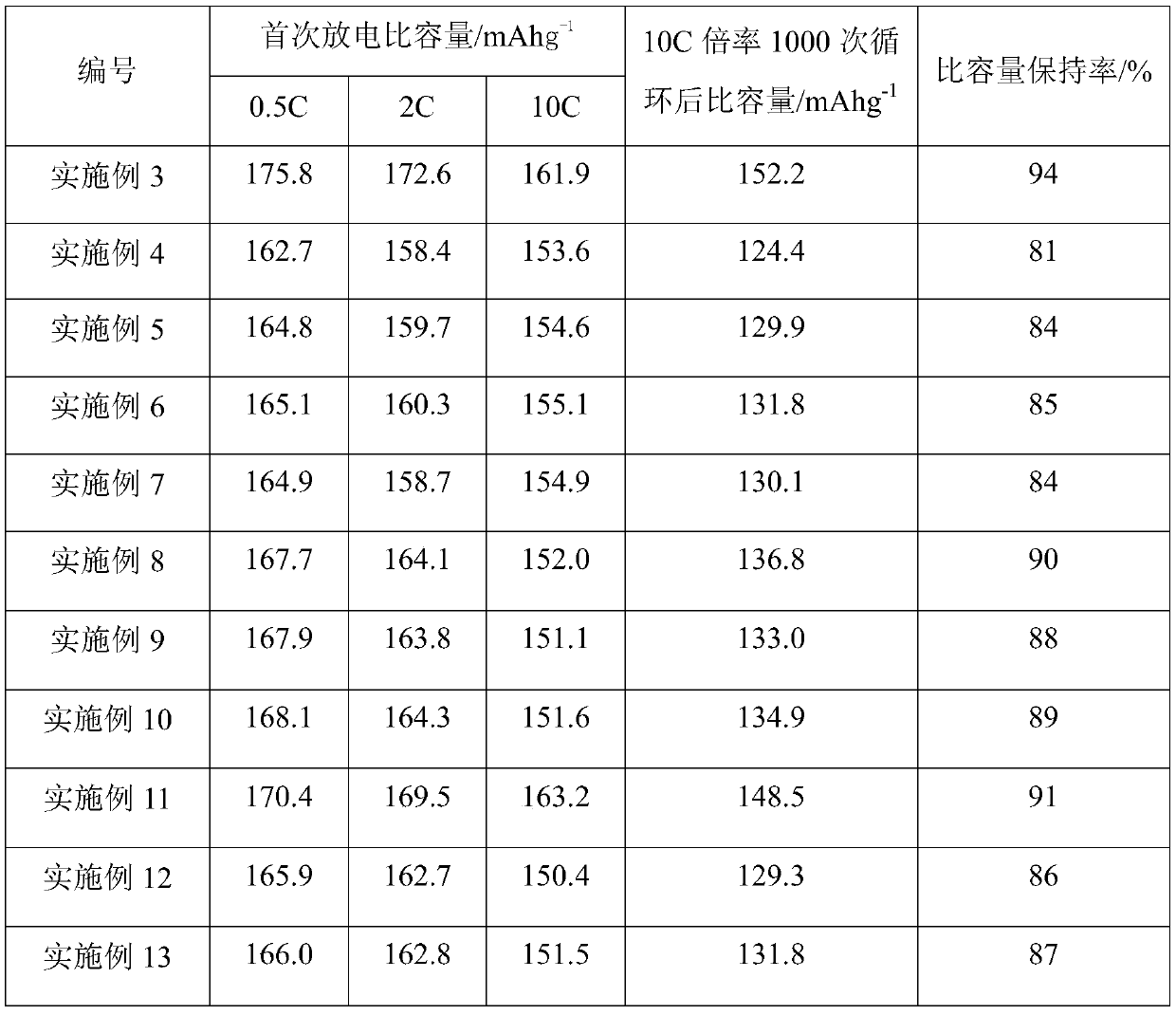

Examples

Embodiment 1

[0024] A lithium iron phosphate lithium battery cathode material, comprising:

[0025] The positive active material is modified lithium iron phosphate doped with 0.1% titanium by mass, 0.2% magnesium by mass and 0.1% silver by mass; the preparation method of the positive active material is specifically:

[0026] 1) Using ferrous oxalate, lithium carbonate and ammonium dihydrogen phosphate as raw materials, the first lithium iron phosphate pre-synthesized by solid phase method at 673k;

[0027] 2) Divide the first lithium iron phosphate into two equal parts, put the first equal parts of the first lithium iron phosphate, magnesium oxalate and 0.1% polyvinyl alcohol by weight of the first lithium iron phosphate into agate In the ball milling jar, use ceramic grinding balls, and after ball milling for 8 hours, under the protection of nitrogen, keep the temperature at 480°C for 6 hours, and then naturally cool to room temperature to obtain the first prefabricated lithium iron phosp...

Embodiment 2

[0035] A lithium iron phosphate lithium battery cathode material, comprising:

[0036]The positive active material is modified lithium iron phosphate doped with 0.1% titanium by mass, 0.2% magnesium by mass and 0.1% silver by mass; the preparation method of the positive active material is specifically:

[0037] 1) Using ferrous oxalate, lithium carbonate and ammonium dihydrogen phosphate as raw materials, the first lithium iron phosphate pre-synthesized by solid phase method at 673k;

[0038] 2) Divide the first lithium iron phosphate into two equal parts, put the first equal parts of the first lithium iron phosphate, magnesium oxalate and 0.3% polyvinyl alcohol by weight of the first lithium iron phosphate into agate In the ball milling tank, select ceramic grinding balls, and after ball milling for 10 hours, under the protection of nitrogen, keep the temperature at 520°C for 8 hours, and then naturally cool to room temperature to obtain the first prefabricated lithium iron p...

Embodiment 3

[0046] A lithium iron phosphate lithium battery cathode material, comprising:

[0047] The positive active material is modified lithium iron phosphate doped with 0.1% titanium by mass, 0.2% magnesium by mass and 0.1% silver by mass; the preparation method of the positive active material is specifically:

[0048] 1) Using ferrous oxalate, lithium carbonate and ammonium dihydrogen phosphate as raw materials, the first lithium iron phosphate pre-synthesized by solid phase method at 673k;

[0049] 2) Divide the first lithium iron phosphate into two equal parts, put the first equal parts of the first lithium iron phosphate, magnesium oxalate and 0.2% polyvinyl alcohol by weight of the first lithium iron phosphate into agate In the ball milling tank, select ceramic grinding balls, and after ball milling for 9 hours, under the protection of nitrogen, keep the temperature at 500°C for 7 hours, and then naturally cool to room temperature to obtain the first prefabricated lithium iron p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com