Polypropylene composite for automobile bumpers, and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of polypropylene composite materials for automobile bumpers and its preparation, can solve the problems of high material cost, small material specific gravity, and poor balance of rigidity and toughness of materials, so as to meet the requirements of high cost performance and increase relative capacitive, high impact strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0029] Weigh the materials according to the components and weight ratios provided in Table 1. First, mix polypropylene resin, talc, thermoplastic elastomer POE, and propylene-based ternary block copolymer in a high-speed mixer for 10 minutes, and then add antioxidant Agent 1010, antioxidant 168, light stabilizer 770, and processing aid are mixed in a high-speed mixer for 10 minutes, and the temperature is controlled at 55-65°C. After that, the composite material was obtained by melt extrusion and granulation in a twin-screw extruder. The temperature of each section of the extruder was set to 200℃, 210℃, 220℃, 220℃, 220℃, 210℃, and the die temperature was 220℃. The screw speed is 400 rpm.

[0030] The test results are shown in Table 2.

[0031] Table 1: The components and proportions of Example 1-2 (all calculated by weight percentage)

[0032] Component

[0033] Table 2: Example 1-2 test performance (GB)

[0034] Test items

[0035] It can be seen from the above table that the...

Embodiment 3-5

[0037] Weigh the materials according to the components and weight ratio provided in Table 3. First, mix polypropylene resin, talc, thermoplastic elastomer POE, and propylene-based ternary block copolymer in a high-speed mixer for 10 minutes, and then add antioxidant Agent 1010, antioxidant 168, light stabilizer 770, and processing aid are mixed in a high-speed mixer for 10 minutes, and the temperature is controlled at 55-65°C. After that, the composite material was obtained by melt extrusion and granulation in a twin-screw extruder. The temperature of each section of the extruder was set to 200℃, 210℃, 220℃, 220℃, 220℃, 210℃, and the die temperature was 220℃. The screw speed is 400 rpm.

[0038] The test results are shown in Table 4.

[0039] Table 3: The components and proportions of Examples 3-5 (all in weight percentage)

[0040] Component

[0041] Table 4: Example 3-5 Test Performance (GB)

[0042] Test items

[0043] It can be seen from the above table that the performanc...

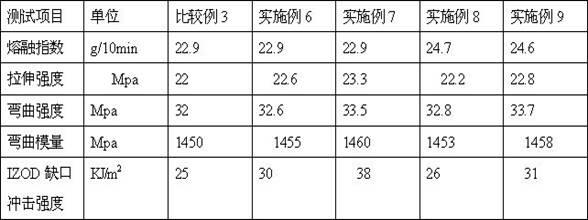

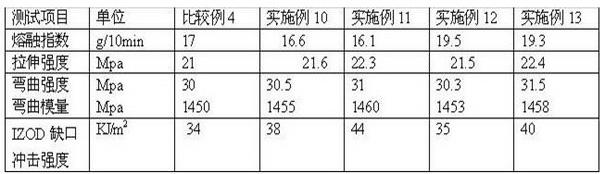

Embodiment 6-9

[0045] Weigh the materials according to the components and weight ratios provided in Table 5. First, mix polypropylene resin, talc, thermoplastic elastomer POE, and propylene-based ternary block copolymer in a high-speed mixer for 10 minutes, and then add antioxidant Agent 1010, antioxidant 168, light stabilizer 770, and processing aid are mixed in a high-speed mixer for 10 minutes, and the temperature is controlled at 55-65°C. Afterwards, the composite material was obtained by melt-extrusion and granulation in a twin-screw extruder. The temperature of each section of the extruder was set to 200℃, 210℃, 220℃, 220℃, 220℃, 210℃, and the die temperature was 220℃. The screw speed is 400 rpm.

[0046] The test results are shown in Table 6

[0047] Table 5: The components and proportions of Examples 6-9 (all calculated by weight percentage)

[0048] Component

Comparative example 3

Example 6

Example 7

Example 8

Example 9

PP (homopolymer)

19

15

9

18

14

PP (copolymerization)

50

50

50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com