Novel plastic-base enhanced foaming composite material as well as preparation method and application thereof

A composite material and plastic-based technology, which is applied in the field of preparation of new billiard cues, achieves the effects of good effect, simple molding process and not easy to hurt hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

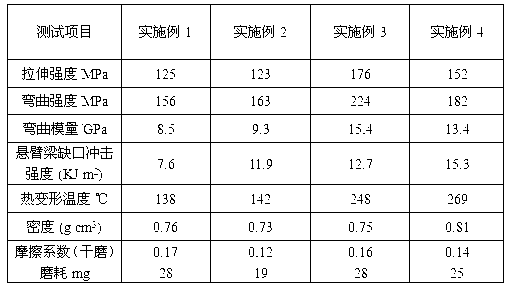

Embodiment 1

[0044] 100 parts of POM, 3 parts of MoS with a particle size of 5000 mesh 2 , 2 parts of MoSi with a particle size of 5000 mesh 2 , 2 parts of ADC, 2 parts of POE-g-MAH, and 0.1 part of silicone powder were mixed in a high-speed mixer at normal temperature for 3 minutes, then melted and extruded through an extruder, cooled, dried, pelletized, and packaged, and 20 parts of carbon fiber were extruded The exit fiber port is introduced, and the carbon fiber diameter is 5 μm. The temperature of the extruder is 120°C, 140°C, 160°C, 170°C, 175°C, 175°C, 180°C, 180°C, 180°C, 185°C from the feeding section to the machine head. Then carry out injection molding to be a billiard cue, and the injection molding temperature is successively 140 ℃, 170 ℃, 180 ℃, 185 ℃ from feeding material to machine head. See Table-1 for basic performance.

Embodiment 2

[0046] 100 parts of PA6, 8 parts of MoS with a particle size of 8000 mesh 2 , 2 parts of MoSi with a particle size of 8000 mesh 2 , 8 parts of OBSH, 8 parts of E-BA, and 1 part of dimethyl silicone oil were mixed with a high-speed mixer at normal temperature for 3 minutes, then melted and extruded through an extruder, cooled, dried, pelletized, and packaged, and 20 parts of basalt fibers were extruded from The exiting fiber port is introduced, and the diameter of the basalt fiber is 20 μm. The temperature of the extruder is 160°C, 180°C, 200°C, 220°C, 225°C, 230°C, 230°C, 230°C, 235°C, 240°C from the feeding section to the machine head. Then carry out injection molding to be billiard cue, and injection molding temperature is 180 ℃, 220 ℃, 235 ℃, 245 ℃ successively from feeding material to machine head. See Table-1 for basic performance.

Embodiment 3

[0048] 100 parts of PA66, 5 parts of MoS with a particle size of 10000 mesh2 , 3 parts of MoSi with a particle size of 10,000 mesh 2 , 6 parts of OBSH, 6 parts of E-MA-GMA, 0.6 parts of simethicone oil mixed with a high-speed mixer at normal temperature for 3 minutes, then melted and extruded through an extruder, cooled, dried, pelletized, packaged, 50 parts of stainless steel fiber Introduced from the fiber port of the extruder, the diameter of the stainless steel fiber is 10 μm. The temperature of the extruder is 240°C, 240°C, 260°C, 260°C, 265°C, 270°C, 270°C, 270°C, 280°C, 285°C from the feeding section to the machine head. Then carry out injection molding to be billiard cue, and injection molding temperature is successively 260 ℃, 280 ℃, 285 ℃, 285 ℃ from feeding material to machine head. See Table-1 for basic performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com