Fire-retardant insulating polyvinyl chloride material and electrical sleeve

A polyvinyl chloride, flame retardant masterbatch technology, applied in insulators, electrical components and other directions, to meet the needs of insulation and flame retardant, excellent flame retardant performance and insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

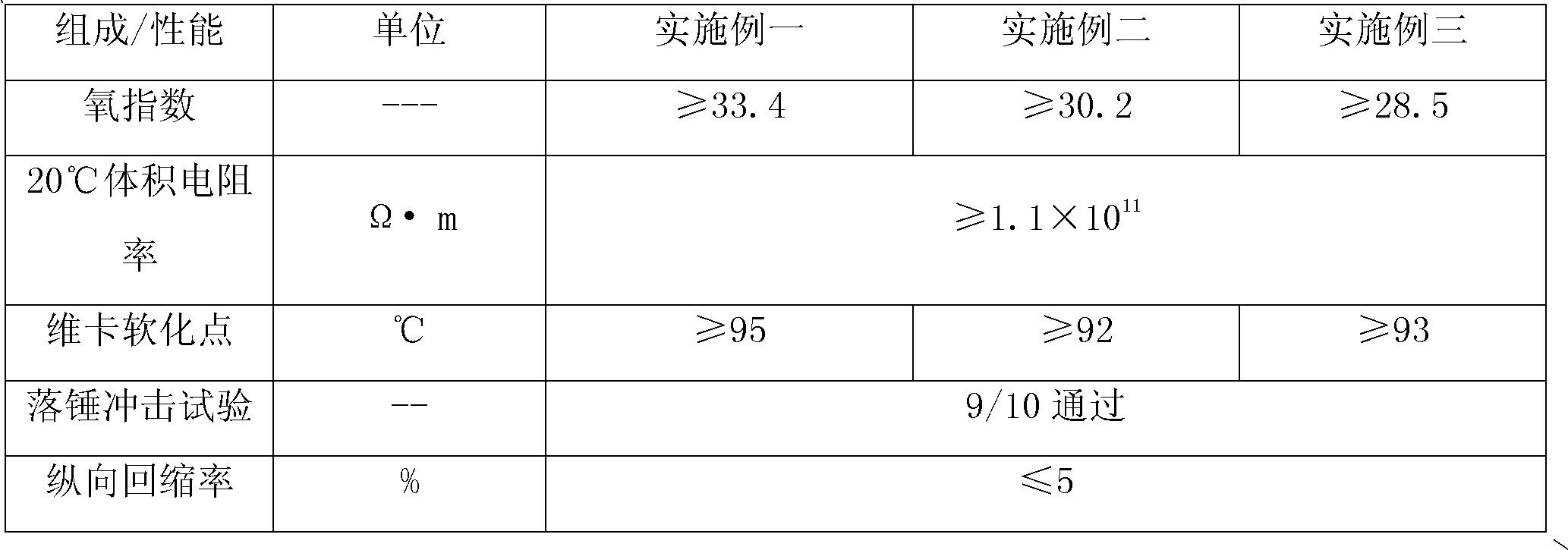

Examples

Embodiment 1

[0057] Ingredient parts by weight

[0058] 120 parts of polyvinyl chloride;

[0059] 60 parts of flame retardant masterbatch;

[0060] 5 parts of chlorinated polyethylene;

[0061] 0.5 part of calcium zinc stabilizer;

[0062] 0.5 parts of polyethylene wax;

[0063] 1 part paraffin;

[0064] ACR401 2 copies;

[0065] 20 copies of MBS;

Embodiment 2

[0069] Ingredient parts by weight

[0070] 150 parts of polyvinyl chloride;

[0071] 50 parts of flame retardant masterbatch;

[0072] 3 parts of chlorinated polyethylene;

[0073] 0.2 part of calcium zinc stabilizer;

[0074] 0.3 parts of polyethylene wax;

[0075] 0.5 parts of paraffin;

[0076] ACR401 1 copy;

[0077] 15 copies of MBS;

[0078] 10 parts of calcium carbonate;

Embodiment 3

[0081] Ingredient parts by weight

[0082] 100 parts of polyvinyl chloride;

[0083] 20 parts of flame retardant masterbatch;

[0084] 2 parts of chlorinated polyethylene;

[0085] 0.2 part of calcium zinc stabilizer;

[0086] 0.3 parts of polyethylene wax;

[0087] 0.5 parts of paraffin;

[0088] ACR401 1 copy;

[0089] 10 copies of MBS;

[0090] 8 parts of calcium carbonate;

[0091] 1.8 parts of rutile titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com