Regenerated cotton fiber and yarn spinning method thereof and textile weaving method

A technology of regenerated cotton yarn and regenerated cotton, which is applied in the field of regenerated cotton fiber and its yarn spinning, textile weaving, and can solve problems such as difficulty in ring spinning, poor fiber cohesion, and short regenerated cotton fibers, so as to promote The effect of green circular low-carbon development, realization of recycling, and realization of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

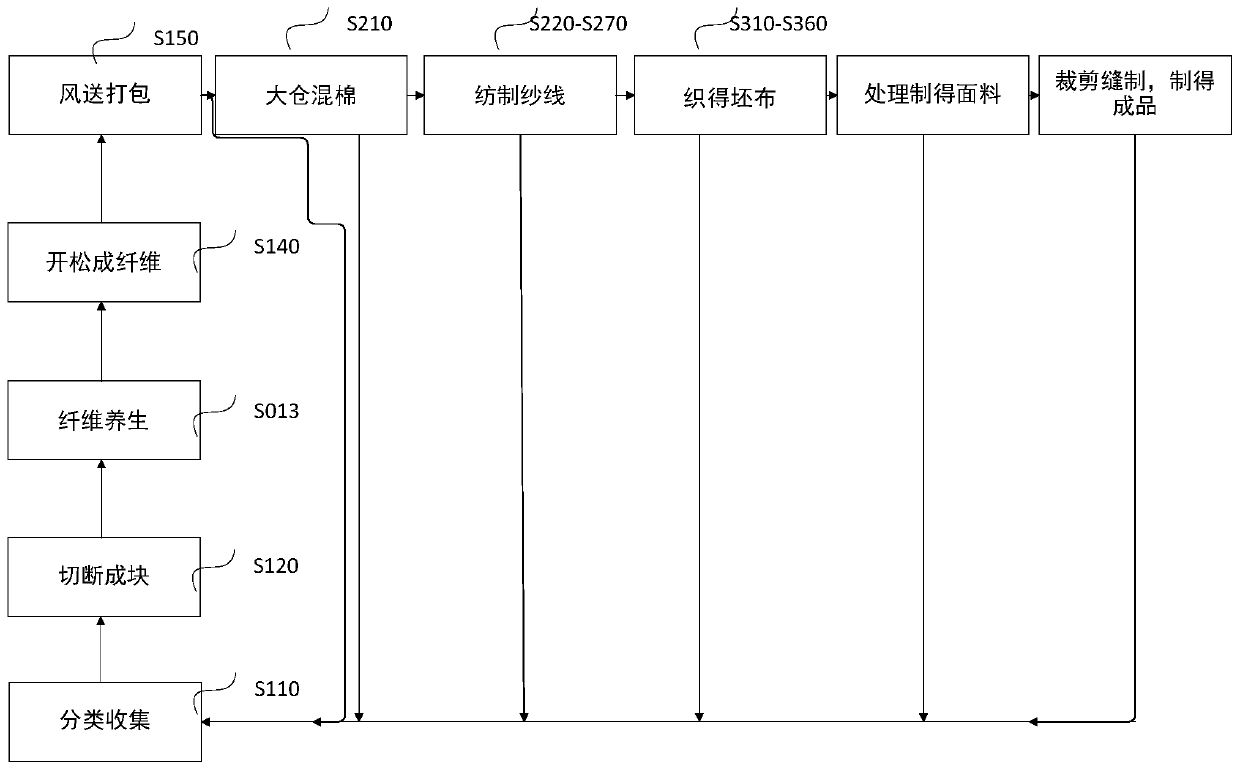

[0046] Example 1 of the present invention provides a regenerated cotton fiber, and its preparation method includes the following steps:

[0047] Step S110, classified collection.

[0048] First remove the large solid impurities in the waste silk, backspatter, silk waste, waste yarn, scraps, scraps, leftovers, and other materials, and then classify according to fiber composition and color characteristics to obtain classified textile waste, and Collect in different storage bags.

[0049] Step S120, cut into blocks.

[0050] The classified textile waste is cut into pieces by a cutting machine according to different categories to obtain the classified textile waste fragments. Classification The side length or length dimension of the textile waste scraps is 2-3cm.

[0051] Step S130, fiber health preservation.

[0052] The fiber health-preserving equipment is used to sequentially apply the first health-preserving liquid and the second health-preserving liquid to the classified textile waste...

Embodiment 2

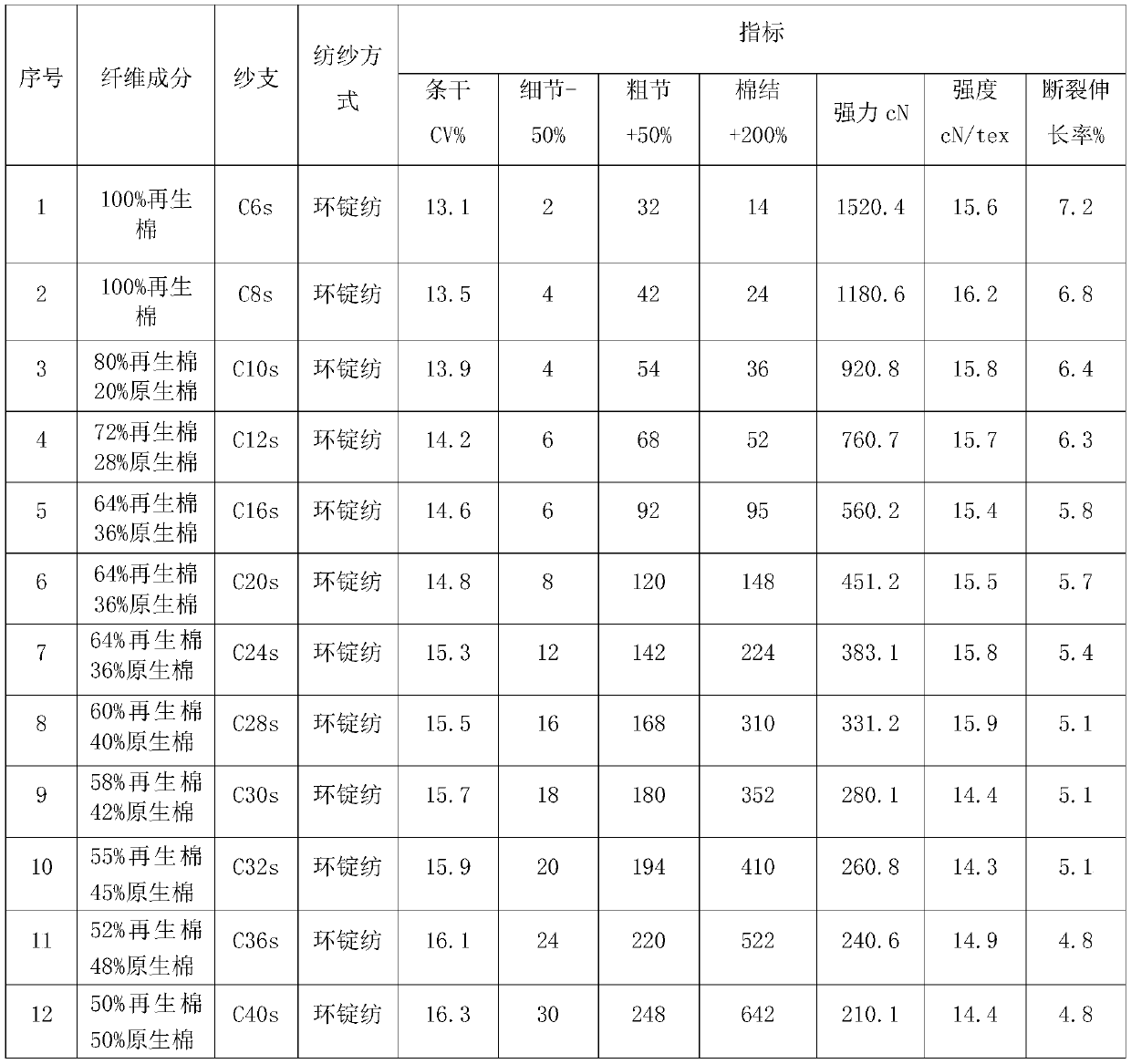

[0060] Embodiment 2 of the present invention provides a method for spinning regenerated cotton yarn. Using the regenerated cotton fiber, virgin cotton fiber, and polyester fiber provided in embodiment 1 of the present invention as raw materials, the regenerated cotton yarn is spun by a ring spinning method. The regenerated cotton yarn is a pure spun yarn of regenerated cotton fiber or a blended yarn of regenerated cotton fiber and virgin cotton fiber and / or polyester fiber, and the count of the regenerated cotton yarn is 3-40S.

[0061] Specifically, the spinning process is pretreatment and cotton assembling → blowing → carding → drawing → roving → spinning → winding → bale formation.

[0062] Step S210, pretreatment and cotton mixing process.

[0063] Put the regenerated cotton fiber or regenerated cotton fiber and virgin cotton fiber and / or polyester fiber into the predetermined raw cotton balance, fully absorb moisture and maintain health under the temperature and humidity conditi...

Embodiment 3

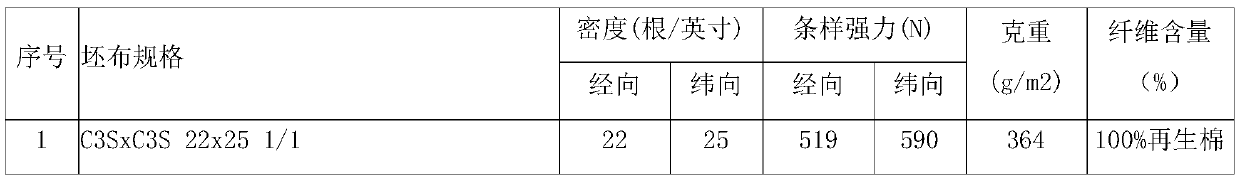

[0081] This Example 3 provides a method for weaving regenerated cotton textiles, using the regenerated cotton yarn obtained by the method provided in Example 2. The weaving process is low-tension and low-speed warping → warp yarn air low-temperature plasma treatment → warp yarn pre-wet sizing → warp yarn reed → low-tension weaving → grey fabric inspection and finishing. specifically:

[0082] Step S310, low-speed warping with small tension.

[0083] According to the specifications and process requirements of the grey fabric, the warp yarns are wound on the warp beams of the warping machine to obtain the warp beams. The warping machine controls the tension of the regenerated cotton yarn through the number of tension grids to uniformly distribute the tension of the entire shaft; the speed of the warping machine is less than or equal to 600r / min, The weight of the tension sheet is 20g. The first third of the warping machine is configured for 3 grids, the middle third of the tension i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Body length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com