A kind of multifunctional environment-friendly universal textile size and preparation method thereof

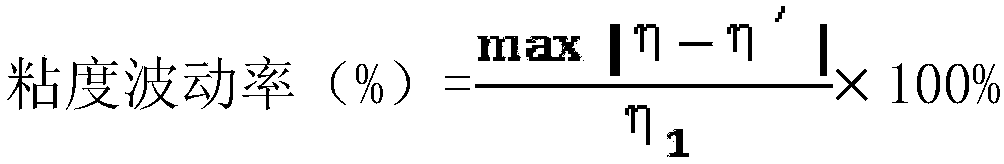

A textile size, general-purpose technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of low sizing rate, poor stability, poor fiber affinity, etc., and achieve high sizing rate and stable viscosity , Moisture absorption and low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of multi-functional environment-friendly general-purpose textile size, by weight, comprises the following components:

[0036] Chitosan 3 parts, acetate starch 15 parts,

[0037] 1 part of carboxymethyl cellulose, 0.5 part of bentonite,

[0038] 2 parts of sodium silicate, 5 parts of itaconic acid,

[0039] 5 parts of acrylamide, 4 parts of butyl acrylate,

[0040] 2 parts of vinyl acetate, 1 part of initiator,

[0041] 0.8 parts of catalyst, 2 parts of calcium chloride, 5 parts of deionized water.

[0042] Its preparation method comprises the following steps:

[0043] (1) mix chitosan, calcium chloride and deionized water, stir until dissolving, obtain mixed solution;

[0044] (2) Mix itaconic acid, acrylamide, butyl acrylate, vinyl acetate and deionized water, heat up to 50-60°C, add bentonite, initiator and catalyst, stir and mix evenly, heat up to 70°C, and react for 2 hours , cooled to room temperature, under the power of 500W, ultrasonication for 1h, ...

Embodiment 2

[0047] A kind of multi-functional environment-friendly general-purpose textile size, by weight, comprises the following components:

[0048] Chitosan 9 parts, acetate starch 20 parts,

[0049] 3 parts of carboxymethyl cellulose, 1 part of bentonite,

[0050] 3 parts of sodium silicate, 10 parts of itaconic acid,

[0051] 15 parts of acrylamide, 8 parts of butyl acrylate,

[0052] 6 parts of vinyl acetate, 1.5 parts of initiator,

[0053] 1.5 parts of catalyst, 5 parts of calcium chloride, 10 parts of deionized water.

[0054] Its preparation method comprises the following steps:

[0055] (1) mix chitosan, calcium chloride and deionized water, stir until dissolving, obtain mixed solution;

[0056] (2) Mix itaconic acid, acrylamide, butyl acrylate, vinyl acetate and deionized water, heat up to 50-60°C, add bentonite, initiator and catalyst, stir and mix evenly, heat up to 90°C, and react for 5h , cooled to room temperature, and ultrasonicated for 3 hours at a power of 500W...

Embodiment 3

[0059] A kind of multi-functional environment-friendly general-purpose textile size, by weight, comprises the following components:

[0060] Chitosan 4 parts, acetate starch 16 parts,

[0061] 1.5 parts of carboxymethyl cellulose, 0.6 parts of bentonite,

[0062] 2.2 parts of sodium silicate, 6 parts of itaconic acid,

[0063] 7 parts of acrylamide, 5 parts of butyl acrylate,

[0064] 3 parts of vinyl acetate, 1.1 parts of initiator,

[0065] 0.9 parts of catalyst, 3 parts of calcium chloride, 6 parts of deionized water.

[0066] Its preparation method comprises the following steps:

[0067] (1) mix chitosan, calcium chloride and deionized water, stir until dissolving, obtain mixed solution;

[0068] (2) Mix itaconic acid, acrylamide, butyl acrylate, vinyl acetate and deionized water, heat up to 50-60°C, add bentonite, initiator and catalyst, stir and mix evenly, heat up to 75°C, and react for 3 hours , cooled to room temperature, under the power of 500W, sonicated for 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com