Amphoteric polymer resins that increase the rate of sizing development

A polymer reaction product, amphoteric technology, applied in the directions of non-fiber pulp addition, papermaking, water repellent addition, etc., can solve the problem of no discovery, and achieve the effect of reducing the dosage and improving the sizing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] The preparation of the polymerization product is preferably carried out by chain polymerization of the monomers of the formulas (I) and (II). In addition, monomers of formulas (III), (IV) and (V) can be synthesized by chain polymerization in the presence of a radical polymerization initiator.

[0102] The polymerization reaction of the diallyl type monomer component and the organic acid is carried out in a suitable solvent, preferably a polar solvent. Water is a particularly preferred solvent for polymerization reactions. Other polar solvents that do not adversely affect the polymerization reaction can also be used. One factor to consider in selecting a suitable solvent is the possibility of a reaction between the initiator used and the solvent that would hinder the polymerization.

[0103] Suitable solvents also include water mixed with solvents that are miscible with water and that do not adversely affect the polymerization reaction.

[0104] The amount of water or...

Embodiment 10

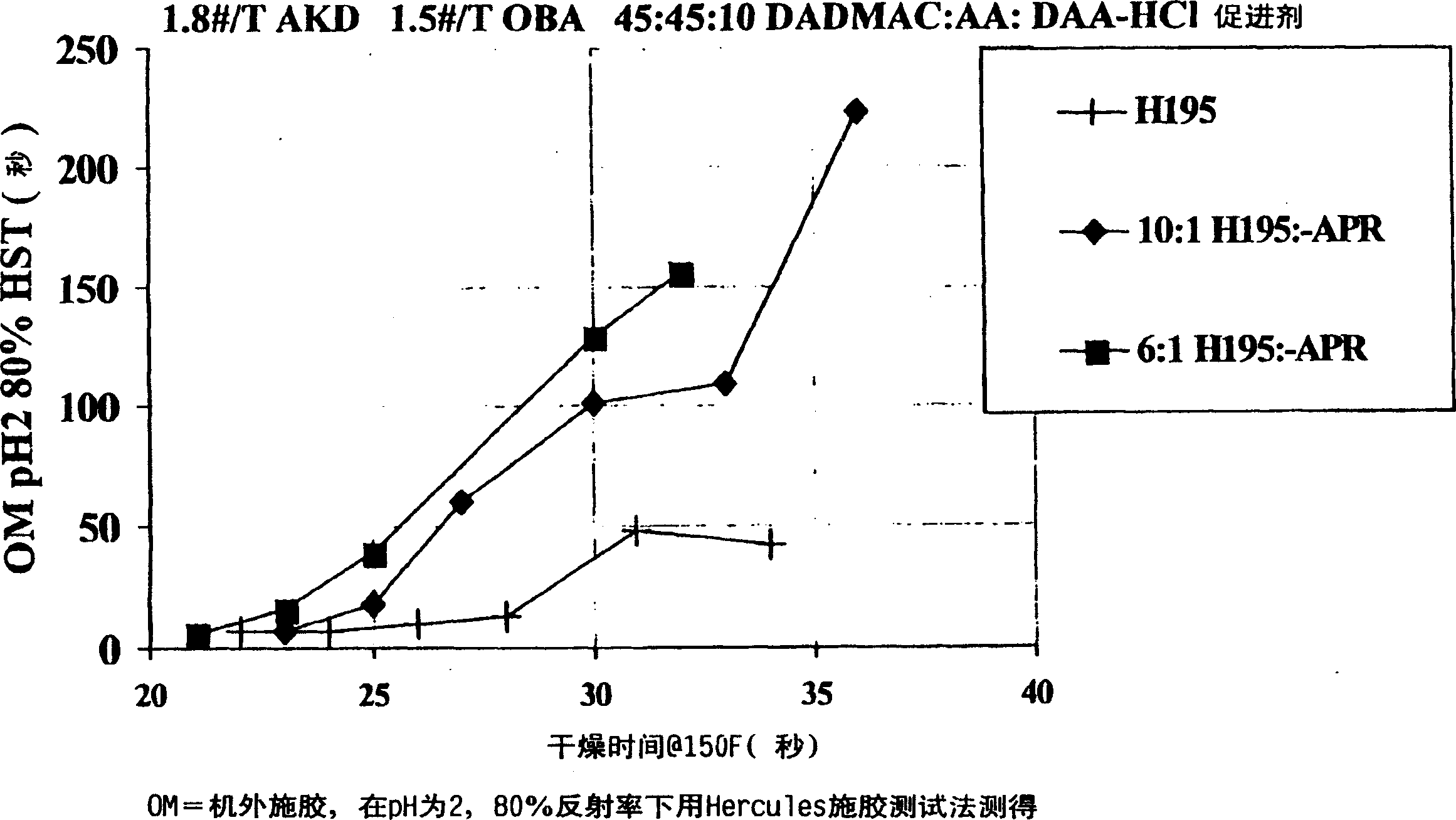

[0316] Papermaking Example 10: Using amphoteric accelerator resins in a pilot paper machine Hercon 195 Sizing Compared to Hercon 79 Sizing

[0317] The pilot paper machine was commissioned to operate with an 80 / 20 weight ratio mixture of hardwood and softwood pulps. Various chemicals are added to the pulp. The amounts of chemicals added are given below. The percentages listed are based on assumed values fully retained in the paper. This assumed value is a useful approximation for the paper machine used in the study. The values listed are estimated weight percents in the finished paper (again assuming full retention). If the examples say that 0.5% starch is added, it means that the finished paper is composed of about 99.5% dry pulp and other additives and 0.5% starch. For this example, the chemicals added were as follows: 0.5% low molecular weight cationic starch, 14% ground calcium carbonate, 0.1% particulate retention / drainage aid mixed with 0.015% acrylamide base...

Embodiment 11-19

[0324] Examples 11-19: Amphoteric Accelerator Resins: Paper Size Press at Lab Scale Test on device

[0325] The following general paper preparation, handling and testing were carried out in Examples 11-19.

[0326] The base paper was previously manufactured on a pilot paper machine at Western Michigan University using a 75:25 mixture of hardwood and softwood bleached pulp. This base paper is similar to copy paper made in the USA. Its quantitative is 75g / m 2 , containing 15% precipitated calcium carbonate. For the current application, no starch or sizing agents were added.

[0327] Base paper was processed in a laboratory size press. The base paper is passed through the chute of the size press and through two rolls. Each treated sample was immediately dried on a tumble dryer at 65°C. The drying time in the dryer was varied to mimic different times and degrees of drying in a paper machine. Each sample was tested separately for relative sizing at different drying times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com