Anti-static PET (Polyethylene Terephthalate) material membrane as well as preparation method and application thereof

A material film and anti-static technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of harmful parts of the human body, damage to electrical or electronic parts of the protective film, and easy adsorption of dust and impurities, etc., to achieve Fast automatic exhaust, easy to operate and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

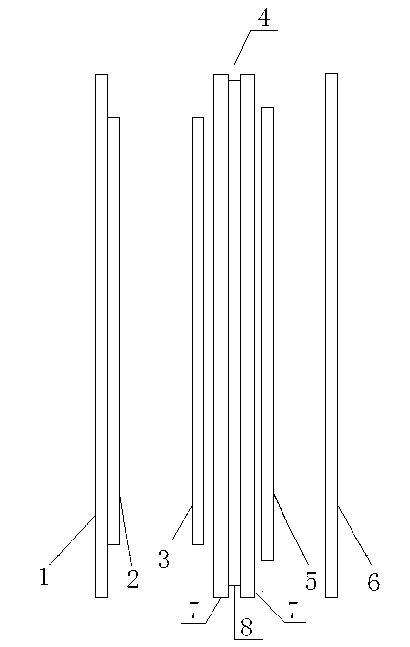

[0032] An antistatic PET material film, which includes a PET coating protective layer 1, a protective film adhesive layer 2, an anti-scratch layer 3, a composite main film PET substrate layer 4, an installation adhesive layer 5 and an installation adhesive protective film PET substrate layer 6. Wherein, composite main film PET substrate layer 4 is composited with installation adhesive layer 5, and installation adhesive protective film PET substrate layer 6 is composited with installation adhesive layer 5; Composite main film PET substrate layer 4 is composited with anti-scratch layer 3; PET coating The film protection layer 1 is combined with the protective film adhesive layer 2; the protective film adhesive layer 2 is combined with the scratch-resistant layer 3; wherein, the scratch-resistant layer 3 contains a conductive polymer, and the conductive polymer is polythiophene.

[0033] The concrete steps of the manufacture method of above-mentioned antistatic PET material film ...

Embodiment 2

[0041] An antistatic PET material film, which includes a PET coating protective layer 1, a protective film adhesive layer 2, an anti-scratch layer 3, a composite main film PET substrate layer 4, an installation adhesive layer 5 and an installation adhesive protective film PET substrate layer 6; wherein, composite main film PET substrate layer 4 is composited with installation adhesive layer 5, and installation adhesive protection film PET substrate layer 6 is composited with installation adhesive layer 5; composite main film PET substrate layer 4 is composited with anti-scratch layer 3; The PET coating protective layer 1 is combined with the protective film adhesive layer 2; the protective film adhesive layer 2 is combined with the scratch-resistant layer 3; wherein, the composite main film PET substrate layer 4 and the installation adhesive layer 5 all contain conductive polymers, and the conductive The polymer is a mixture of polyacetylene, polypyrrole and polyaniline.

[00...

Embodiment 3

[0051] An antistatic PET material film, which includes a PET coating protective layer 1, a protective film adhesive layer 2, an anti-scratch layer 3, a composite main film PET substrate layer 4, an installation adhesive layer 5 and an installation adhesive protective film PET substrate layer 6; wherein, composite main film PET substrate layer 4 is composited with installation adhesive layer 5, and installation adhesive protection film PET substrate layer 6 is composited with installation adhesive layer 5; composite main film PET substrate layer 4 is composited with anti-scratch layer 3; The PET coating protective layer 1 is combined with the protective film adhesive layer 2; the protective film adhesive layer 2 is combined with the scratch-resistant layer 3; wherein, the scratch-resistant layer 3, the composite main film PET substrate layer 4 and the installation adhesive layer 5 Both contain conductive polymer, and the conductive polymer is a mixture of polyphenylene, polyphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com