Anti-glare screen protection film

A screen protection film, anti-glare technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc. Aesthetics and other issues, to achieve the effect of eliminating reflected light and strong glare, rich colors, and strong fashion sense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

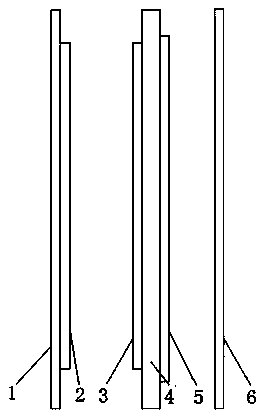

[0033] An anti-glare screen protective film, comprising: a main film PET substrate (4) with a thickness of 100um, an installation adhesive layer (5) with a thickness of 25um, a PET substrate (6) with a thickness of 50um for the installation adhesive protection film, An anti-glare and anti-scratch layer (3) with a thickness of 2um, a protective film adhesive layer (2) with a thickness of 5um, and a PET substrate (1) for the anti-scratch layer protective film with a thickness of 50um.

[0034] In this embodiment, the protective film adhesive layer (2), the anti-glare anti-scratch layer (3) and the installation adhesive layer (5) are all made of acrylic resin; the anti-scratch layer protective film PET substrate (1), the main film PET The base material (4) and the mounting adhesive protective film PET base material (6) are all PET films, and the light transmittance of the PET film is greater than 92%, and the haze is less than 1%.

[0035] The specific steps of the manufacturing ...

Embodiment 2

[0041] An anti-glare screen protective film, which includes: a main film PET base material (4) with a thickness of 50um, an installation adhesive layer (5) with a thickness of 40um, a PET base material (6) with a thickness of 12um for the installation adhesive protection film, An anti-glare and anti-scratch layer (3) with a thickness of 4um, a protective film adhesive layer (2) with a thickness of 10um, and a PET base material (1) for the anti-scratch layer protective film with a thickness of 36um.

[0042] In this embodiment, the protective film adhesive layer ( 2 ) and the installation adhesive layer ( 5 ) are both made of silicone resin; the anti-glare and scratch-resistant layer ( 3 ) is made of acrylic resin. Scratch-resistant layer protective film PET base material (1), main film PET base material (4), and mounting adhesive protective film PET base material (6) are all PET films, and the light transmittance of the PET film is greater than 92%, and the haze less than 1%. ...

Embodiment 3

[0049] An anti-glare screen protective film, comprising: a main film PET substrate (4) with a thickness of 250um, an installation adhesive layer (5) with a thickness of 10um, a PET substrate (6) with a thickness of 36um for the installation adhesive protection film, An anti-glare and anti-scratch layer (3) with a thickness of 8um, a protective film adhesive layer (2) with a thickness of 20um, and a PET base material (1) for the anti-scratch layer protective film with a thickness of 12um.

[0050] In this embodiment, the protective film adhesive layer (2), the installation adhesive layer (5) and the anti-glare anti-scratch layer (3) are all made of silicone resin; the anti-scratch layer protective film PET substrate (1), The PET base material (4) of the main film and the PET base material (6) of the installation adhesive protective film are all PET films, and the light transmittance of the PET film is greater than 92%, and the haze is less than 1%.

[0051] The specific steps o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com