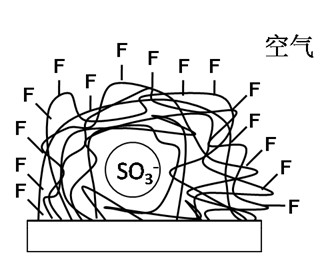

Humidity-sensitive intelligent betaine fluorinated antifouling paint and preparation method thereof

A technology of humidity sensing and antifouling paint, applied in the field of paint, can solve the problem that the effect of underwater paint is not very ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

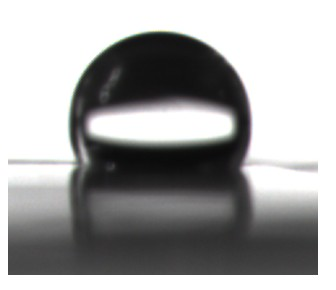

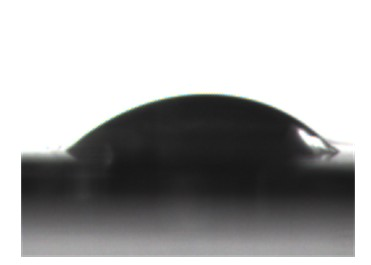

[0035] Example 1 Add 44 parts of water (parts by weight, the same below) and 0.7 parts of tributyl phosphate as an antifoaming agent into a 500mL beaker, and stir until fully mixed. Then gradually add 100 parts of the above-mentioned betaine fluorine-containing copolymer emulsion, and mix evenly with the offset paper. Finally, add 3 parts of sodium hexametaphosphate as a dispersant and 15 parts of talcum powder as a filler, and stir at high speed for 20 to 30 minutes until homogeneous.

[0036] The betaine-based fluorine-containing paint was coated on the surface of a glass slide, and its performance was measured after drying.

[0037] After 3 weeks of testing, in the environment with the same fouling organisms, the number of fouling organisms on the surface of the betaine-based fluorine-containing coating was significantly less than that on the blank glass (the area was reduced by 95% and thinner fouling biolayer). This fully demonstrates that the betaine-based fluorine-c...

example 2

[0038] Example 2 Add 60 parts of water (parts by weight, the same below) and 0.9 parts of tributyl phosphate as an antifoaming agent into a 500 mL beaker, and stir until fully mixed. Gradually add 100 parts of betaine fluorine-containing copolymer emulsion, and mix evenly with offset paper. Finally, add 6 parts of sodium hexametaphosphate as a dispersant and 20 parts of talcum powder as a filler, and stir at high speed for 20 to 30 minutes until homogeneous.

[0039] The betaine-based fluorine-containing paint was coated on the surface of a glass slide, and its performance was measured after drying.

[0040] After 3 weeks of testing, in the environment with the same fouling organisms, the number of fouling organisms on the surface of the betaine-based fluorine-containing coating was significantly less than that on the blank glass (the area of the fouling organisms was less more than 95% and the fouling biological layer is thinner). This fully demonstrates that the betaine-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com