Large rubber production granulator

A granulator and rubber technology, which is applied in the field of rubber production, can solve the problems of increasing energy input, different melting degrees of rubber raw materials, and affecting the quality of rubber granules, so as to improve utilization rate, ensure heat transfer efficiency, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

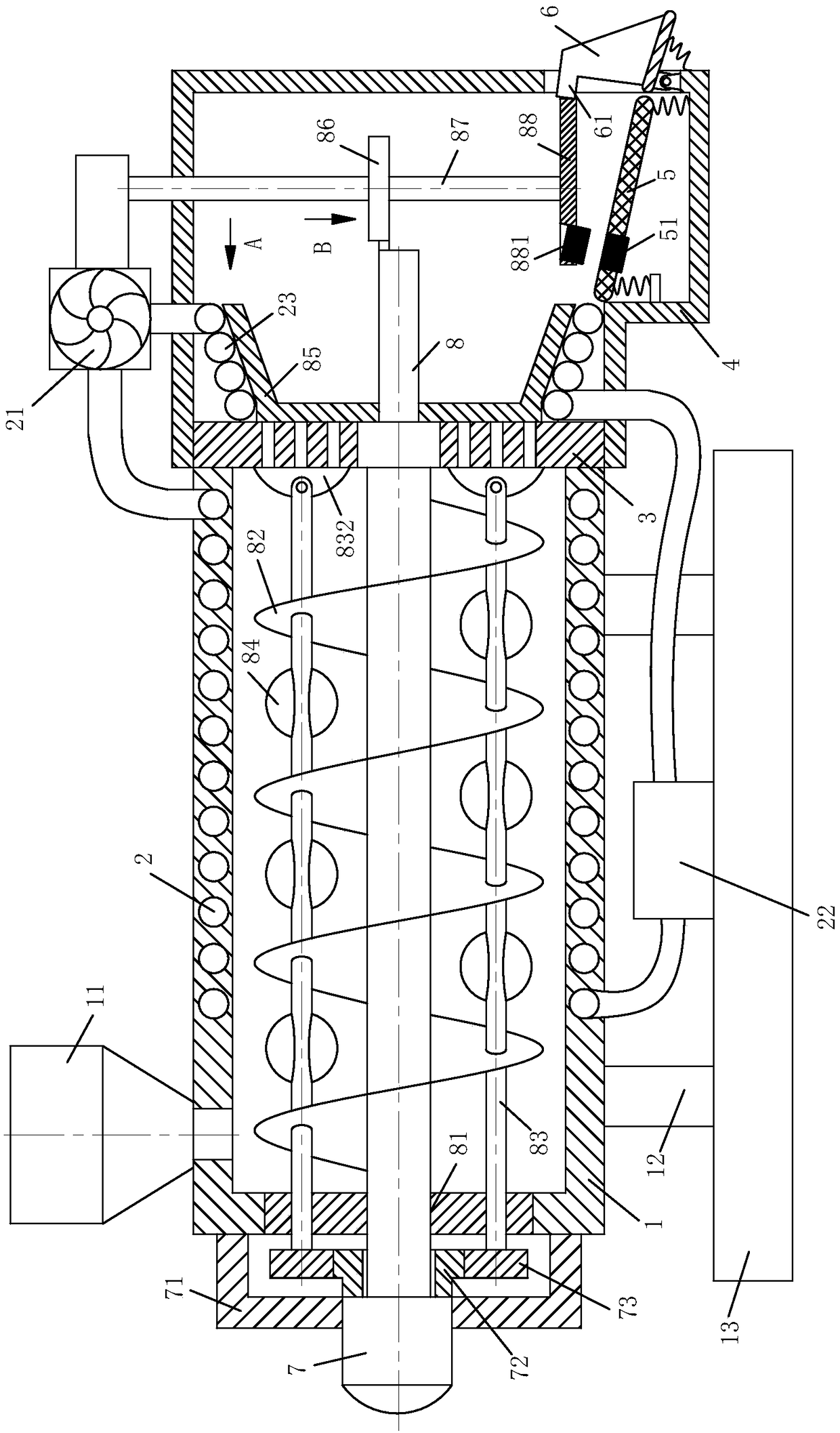

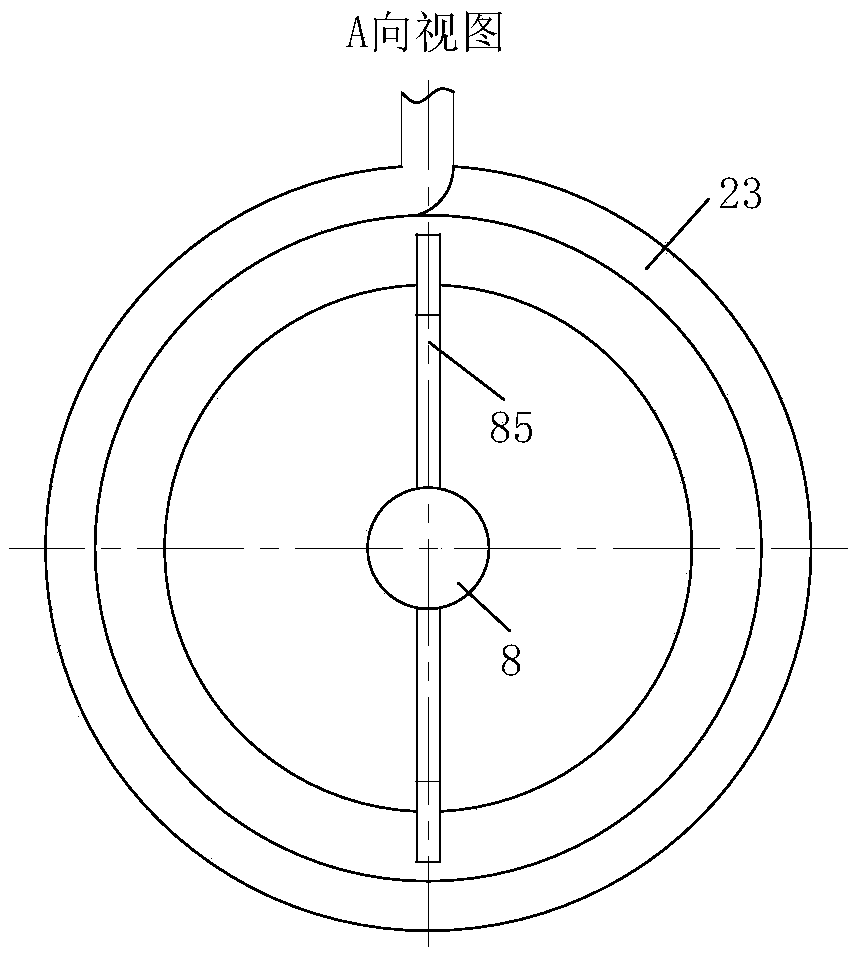

[0026] As an embodiment of the present invention, the inside of the heat recovery water pipe 23 is provided with a set of No. 2 scrapers 85; one end of the No. 2 scrapers 85 is fixedly connected to the cylindrical surface of the transmission shaft 8, and the No. The left end of 85 contacts and cooperates with the right end surface of granulation mold 3, and the right end slope of No. 2 scraper 85 and the inner surface of heat recovery water pipe 23 are provided with a gap; during work, drive shaft 8 drives No. 2 scraper 85 to rotate, and the The left end of the No. 2 scraper 85 cleans the right end of the granulation mold 3, thereby ensuring the cleanliness of the edges of the granulation holes and making the size of the rubber particles more uniform. The rubber particles are flipped up, so that the rubber particles slide along the heat recovery water pipe 23, and then the waste heat of the rubber particles is more fully absorbed by the heat recovery water pipe 23, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com