Reaction kettle

A technology of reaction kettle and shell, applied in the field of chemical equipment, can solve problems such as energy waste, and achieve the effect of overcoming waste, rational utilization and recovery of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

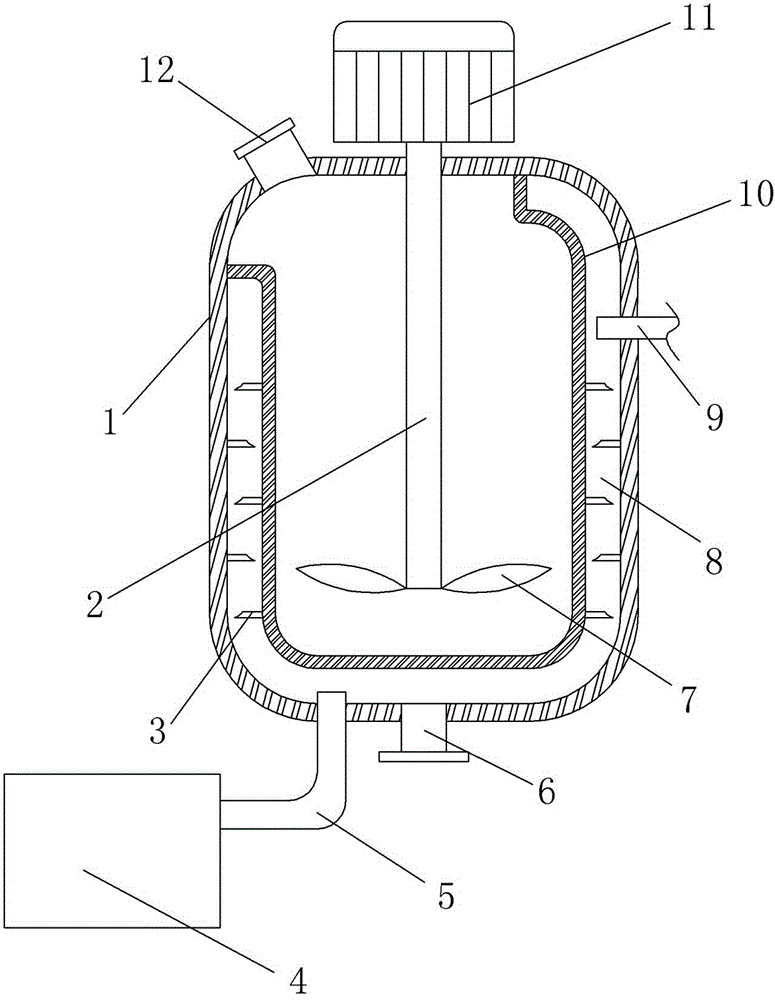

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0012] Such as figure 1 Shown: the present invention provides a kind of reactor, comprises reactor shell 1, feed port 12, discharge port 6, stirring shaft 2 and motor 11, and feed port 12 is arranged on the top of reactor shell 1 body, and outlet The feed opening 6 is set at the bottom of the reactor shell 1, one end of the stirring shaft 2 extends into the reactor shell 1, the end of the stirring shaft 2 is provided with a stirring blade 7, and the other end extends out of the reactor shell 1 and is connected with the motor 11 , an isolation layer 10 is arranged in the reactor housing 1, a water inlet is provided on the top of the reactor housing 1, the water inlet is connected to a water inlet pipe 9, and a valve is arranged on the water inlet pipe 9, and the isolation layer 10 and the reactor housing A water flow channel 8 is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com