Equipment for automatic assembling of heat conducting tube and radiation fins

A technology for radiating fins and assembling equipment, applied in the direction of heat exchange equipment, etc., can solve the problems of manual replacement operations prone to negligence, increase in defect rate, deformation of heat pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

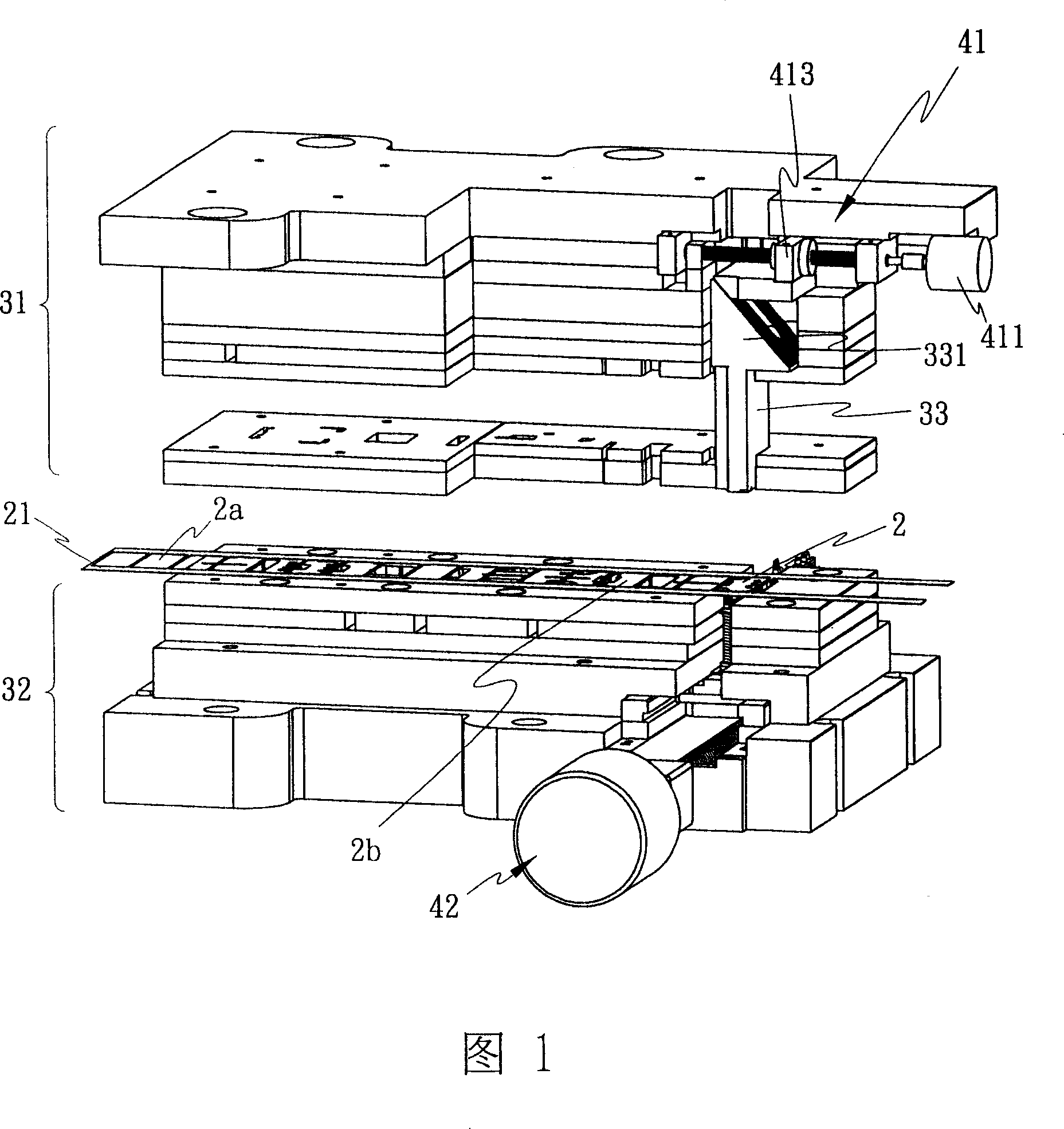

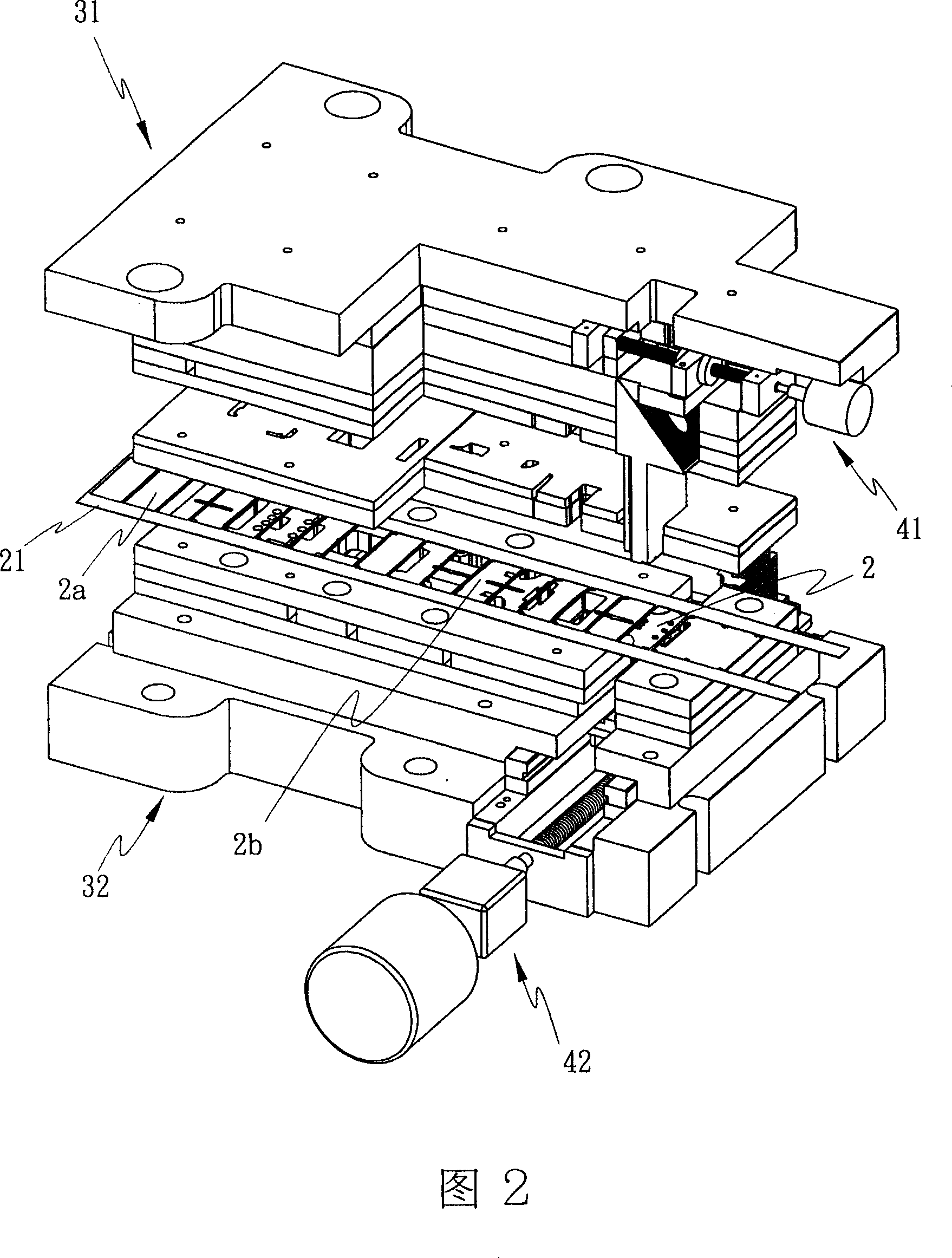

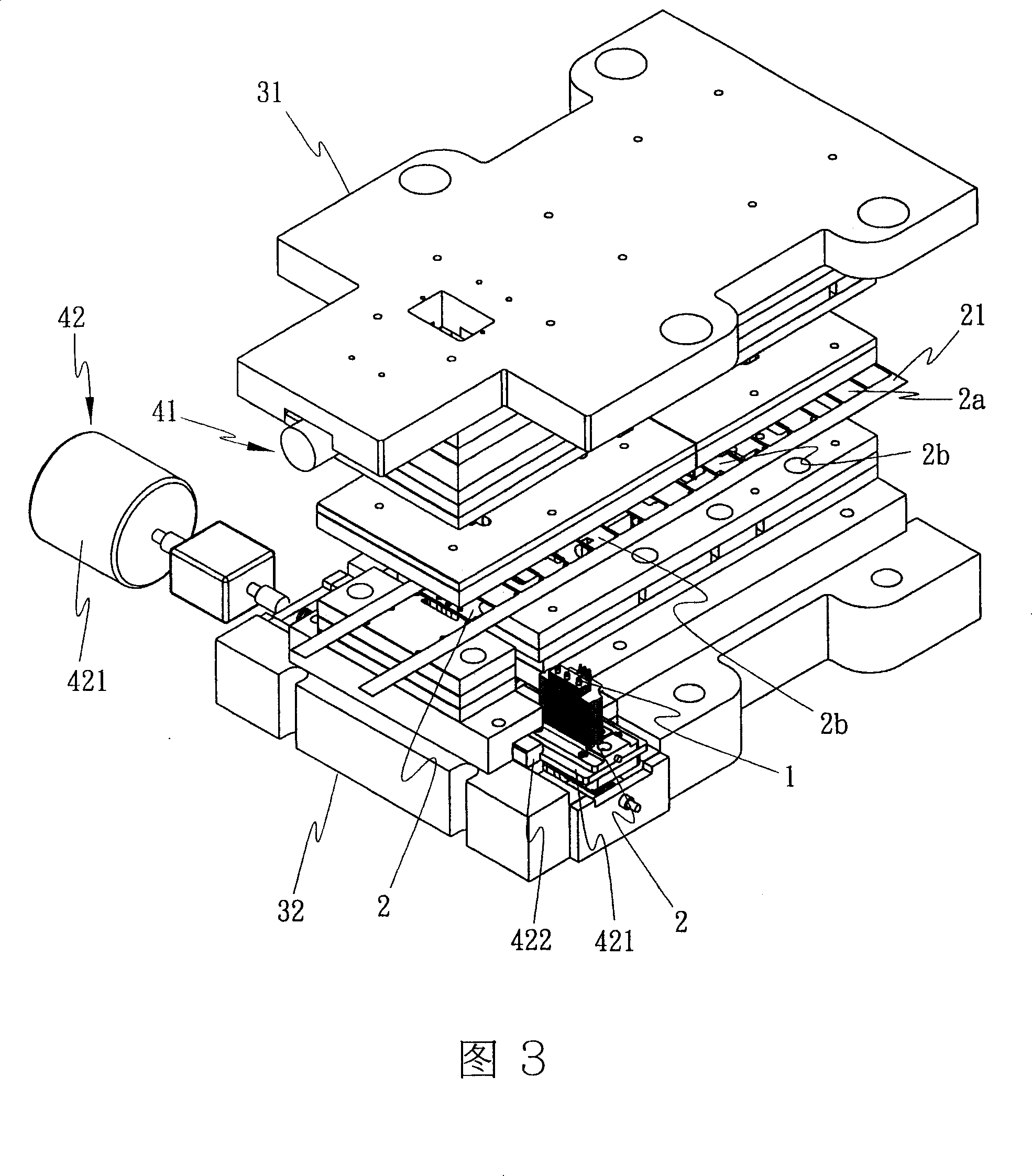

[0019] As shown in Figures 1 to 4, the automatic assembly equipment for heat pipes and radiating fins of the present invention is mainly composed of a continuous stamping die device 3 and two upper and lower transmission mechanisms 41, 42, in which:

[0020] The continuous die device 3 is composed of an upper die 31, a lower die 32 and a punch 33 provided in the upper die 31. In order to cooperate with an automatic feeding device (not shown), the material 2a for the heat dissipation fins including the strip 21 is selected. , The semi-finished fins 2b to the finished product 2 (as shown in Figure 5) are gradually made through the segmented punching process, and the finished fins 2 are accurately delivered to the working position above the worktable 421 of the lower transmission mechanism 42 (such as 6), the finished heat dissipation fin 2 is now completely formed, and has one or more through holes 22 that can be closely matched with the heat pipe 1 to provide one or more heat Cathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com