Efficient and compact pre-cooling heat exchanger for pre-cooling gas sucking type engine

A pre-cooling heat exchanger, aspirating technology, which is used in the cooling of the engine, heat exchanger shell, indirect heat exchanger, etc., can solve the heat exchange effect of the compact circular tube heat exchanger. problems, to reduce the difficulty of welding, avoid frost, and increase the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

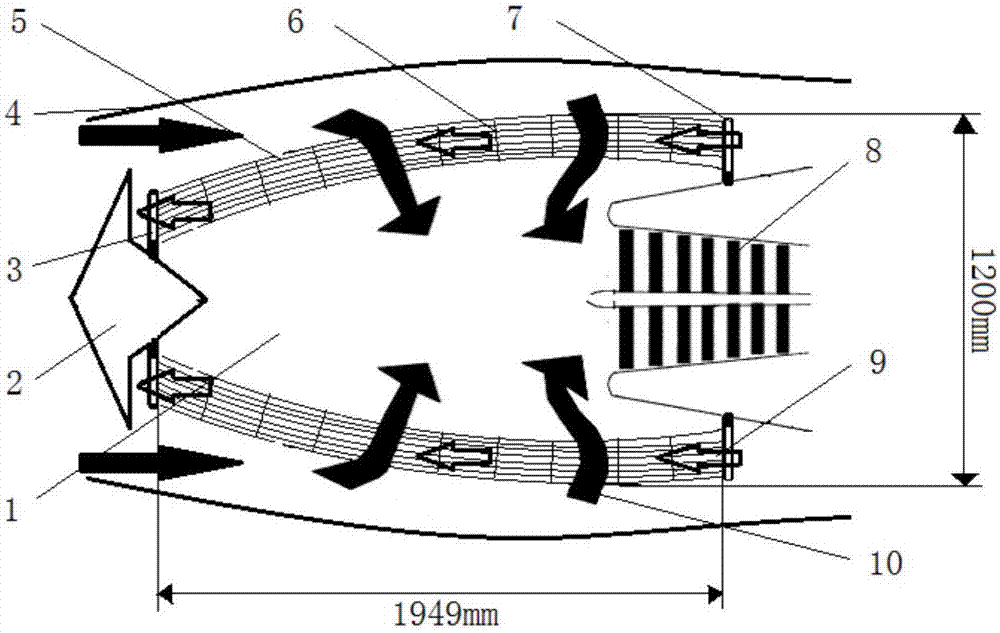

[0046] Such as figure 1 As shown, a high-efficiency and compact pre-cooling heat exchanger for pre-cooling an air-breathing engine includes a pre-cooling heat exchanger body 10, and the pre-cooling heat exchanger body is arranged on the air-breathing engine inlet 2 and the compressor 8 between.

[0047] The shape of the body of the pre-cooling heat exchanger is a cylinder-like shape.

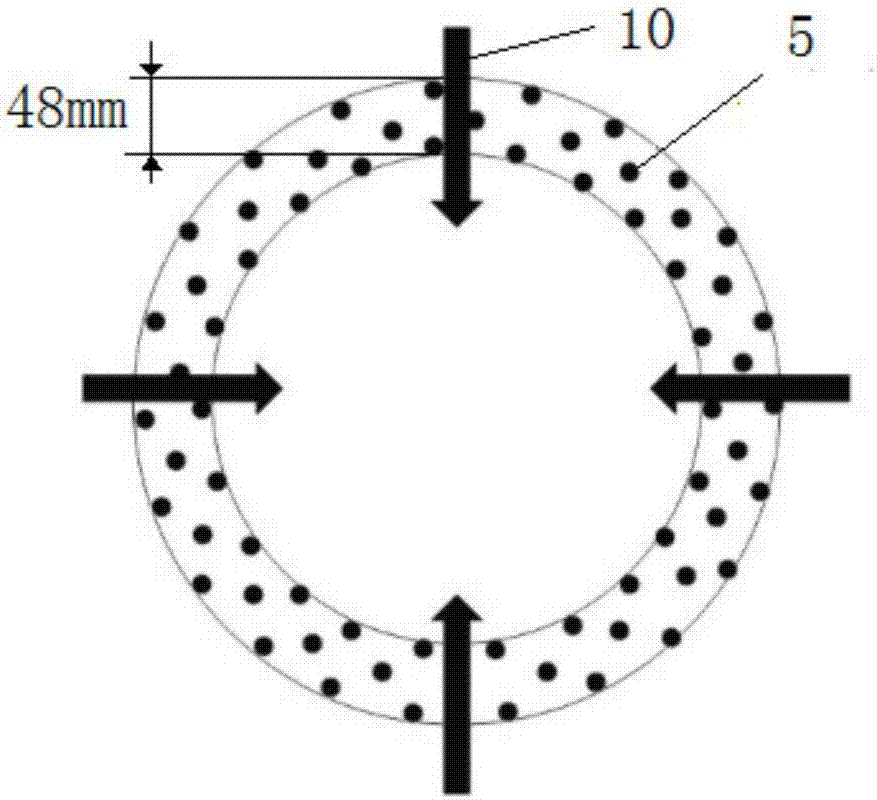

[0048] The cross-section of the cylinder is as figure 2For rings of different diameters shown, the cross-sections at the ends have a smaller diameter than the cross-section in the middle. Hereinafter, the diameter of the annular cross-section with the largest diameter is denoted as the largest diameter.

[0049] The above-mentioned maximum diameter can be adjusted according to the cooling requirements of the air-breathing engine. For ever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com