Loop-type thermosiphon and stirling refrigerator

a technology of thermosiphon and refrigerator, which is applied in the direction of refrigeration machines, domestic cooling apparatus, gas cycle refrigeration machines, etc., can solve the problems of less likely stability of circulation flow rate, no longer using cfc-based refrigerant, and fluctuation of temperature of heat source, etc., to achieve compact structure, promote separation of bubbles adhered to heat absorption portion or the like, and facilitate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

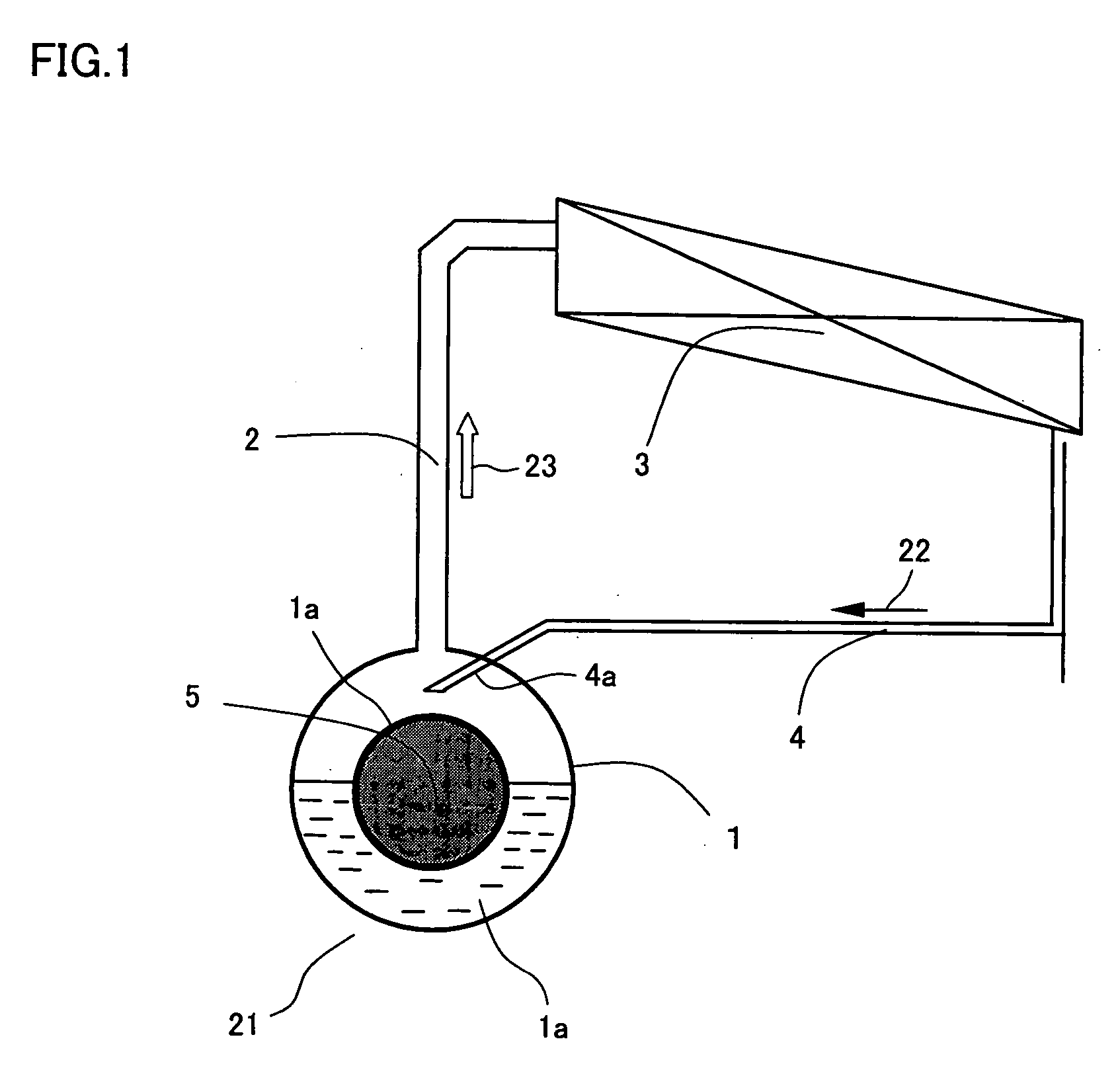

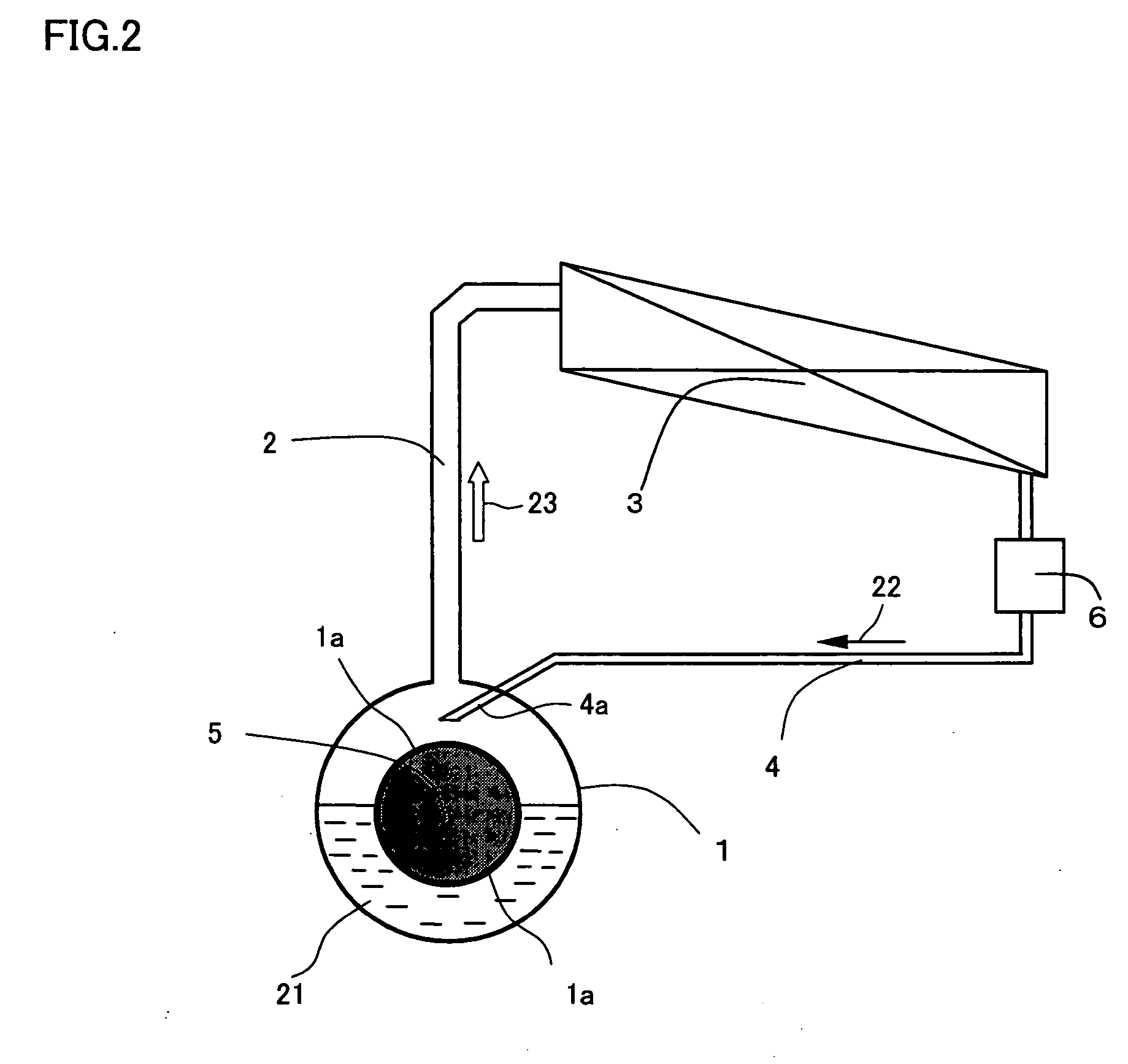

[0023]FIG. 1 is a conceptual diagram illustrating a basic arrangement of a loop-type thermosiphon in a first embodiment of the present invention. The loop-type thermosiphon shown in FIG. 1 is constituted of an evaporator 1, a condenser 3, a gas pipe 2 extending from evaporator 1 to condenser 3, and a liquid pipe 4 extending from condenser 3 to evaporator 1. In the present embodiment, as a high-temperature heat source 5 to be cooled has a cylindrical heat dissipation surface as shown in FIG. 1, the evaporator has an annular shape with a circular hole having a dimension adapted to the cylindrical heat dissipation surface of the heat source. In addition, a surface of the hole of the evaporator is brought in intimate contact with the cylindrical heat dissipation surface of heat source 5 in order to reduce thermal contact resistance. Condenser 3 is of a fin-tube type, and cools a working fluid flowing inside the pipe by flowing air around the same.

[0024] The pipe of the condenser for fl...

second embodiment

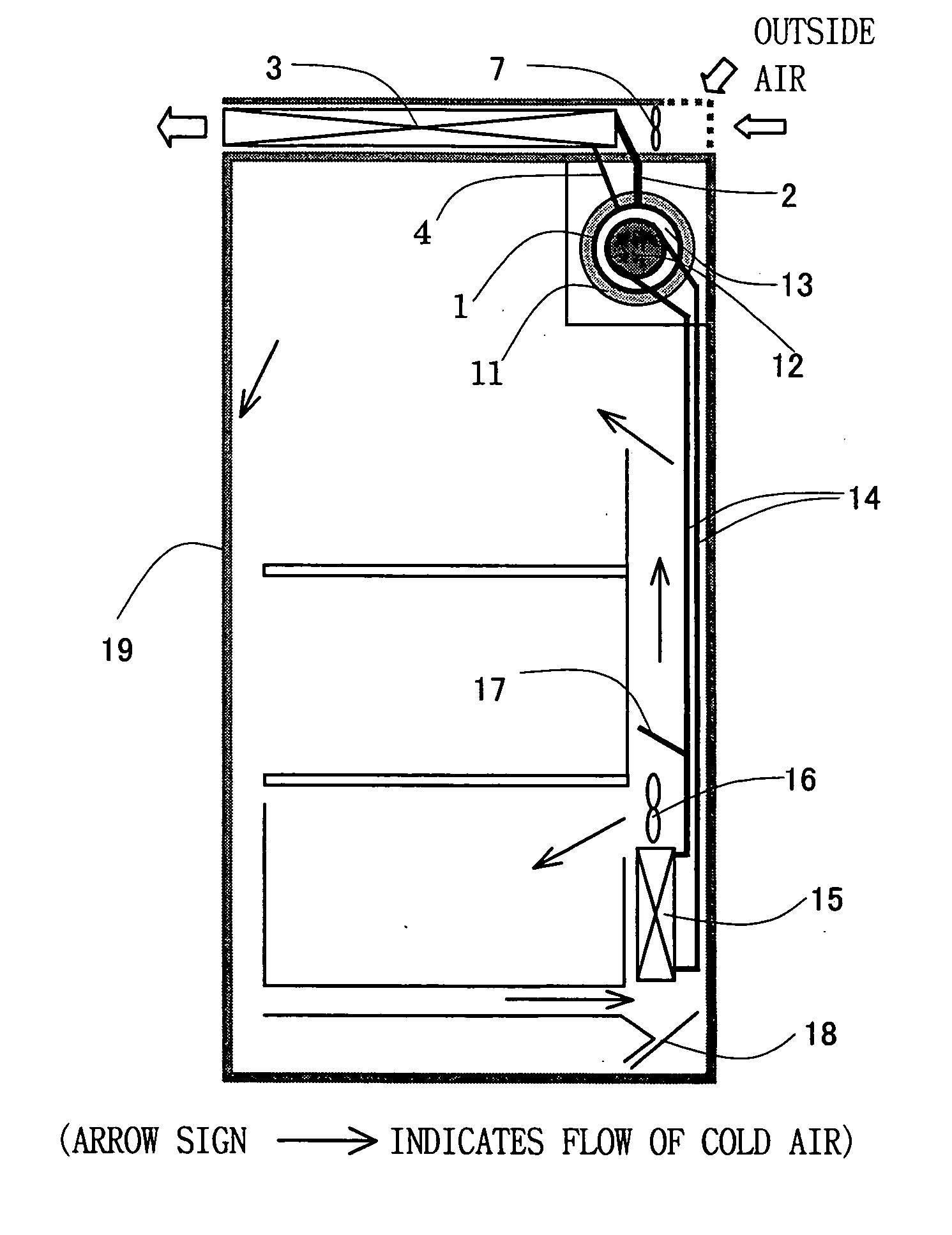

[0031]FIG. 3 is a conceptual diagram of a Stirling refrigerator according to a second embodiment of the present invention, provided with the loop-type thermosiphon. The Stirling refrigerator in FIG. 3 is constituted of a Stirling cooler provided in a refrigerator main body 19, the loop-type thermosiphon attached in order to cool a high-temperature portion of the Stirling cooler, a low-temperature side heat exchange system transferring a cold of a low-temperature portion of the Stirling cooler to the inside of the refrigerator, the refrigerator main body, and the like. Though the low-temperature side heat exchange system is implemented by the loop-type thermosiphon, it is the loop-type thermosiphon not of interest in the present embodiment.

[0032] A Stirling cooler 11 having cylindrical high-temperature and low-temperature portions is arranged on a back surface of the refrigerator. Evaporator 1 of the loop-type thermosiphon cooling a high-temperature portion 13 of the Stirling cooler...

third embodiment

[0037]FIG. 4 shows temperature fluctuation of the high-temperature heat source when a loop-type thermosiphon according to a third embodiment of the present invention is employed. The loop-type thermosiphon in the present embodiment is obtained merely by varying a manner of return of the liquid to the evaporator in the conventional loop-type thermosiphon shown in FIG. 6. In other words, the loop-type thermosiphon is structured such that the condensed working fluid is returned so as to contact with the heat absorption portion not being in contact with the liquid pool, instead of being directly introduced into the liquid pool.

[0038] The variation with time of the temperature of the high-temperature heat source shown in FIG. 4 exhibits an effect obtained under the condition of heat load the same as in the conventional loop-type thermosiphon. As compared with the large temperature fluctuation of the heat source in the conventional loop-type thermosiphon shown in FIG. 7, stable temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com