Scattering treatment method for hydrophilic chopped fiber for fracturing

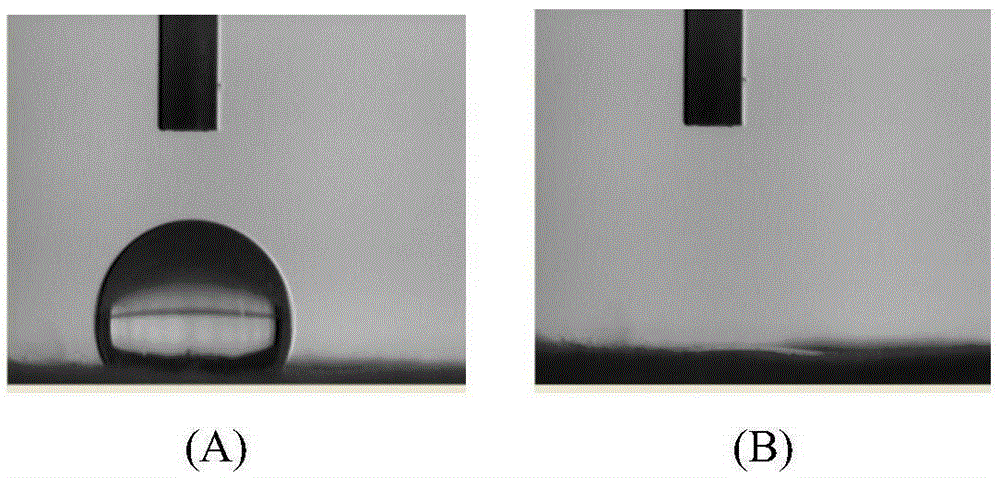

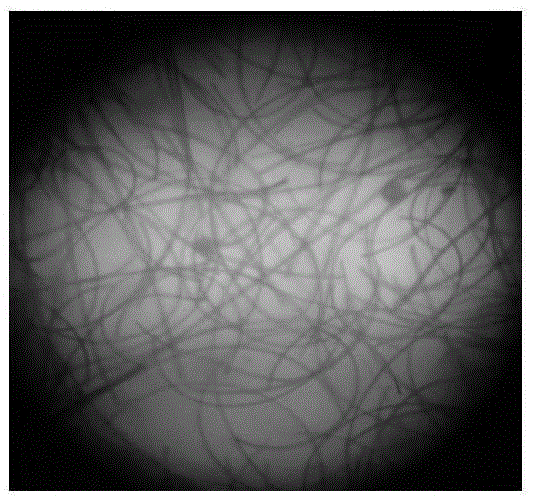

A technology of chopped fibers and a treatment method, which is applied in the field of dispersing treatment of hydrophilic chopped fibers for fracturing, can solve the problems of low sand-carrying performance, difficult to disperse in agglomeration, and fibers floating on the surface of fracturing fluid, etc. The effect of enhancing sand-carrying performance, improving sand-carrying performance and improving fiber fracturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

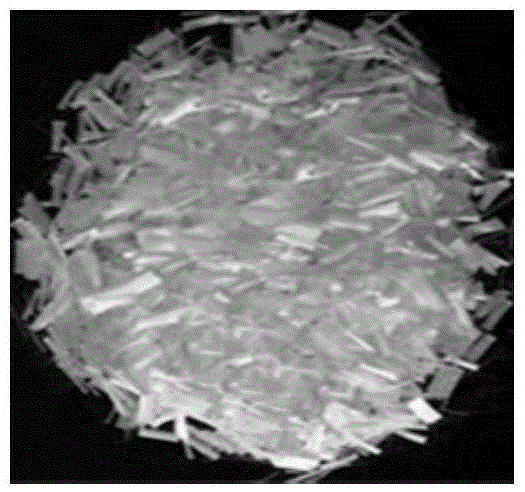

[0046] This embodiment provides undissolved and dispersed hydrophilic chopped fibers for fracturing, wherein the hydrophilic chopped fibers for fracturing are sprayed and impregnated with fiber surface treatment agents After treatment, obtained by drying;

[0047] Among them, the fiber surface treatment agent, based on its total weight as 100%, includes: polyether modified silicone oil 8.2%, γ-glycidyl ether oxypropyltrimethoxysilane 0.35%, Span600.25%, Tween800.42 %, 0.06% of perfluorooctyl polyoxyethylene ether nonionic fluorocarbon surfactant, 0.33% of ethylene glycol, 0.40% of carboxymethyl starch and the balance of deionized water.

[0048] The fiber surface treatment agent is prepared by the following method:

[0049] Add polyether modified silicone oil, γ-glycidyl etheroxypropyltrimethoxysilane, Span60, Tween80, perfluorooctyl polyoxyethylene ether non-ionic fluorocarbon surfactant, Alcohol and carboxymethyl starch were mixed at 40° C. under normal pressure for 2 hour...

Embodiment 2

[0075] This embodiment provides undissolved and dispersed hydrophilic chopped fibers for fracturing, wherein the hydrophilic chopped fibers for fracturing are sprayed and impregnated with fiber surface treatment agents After treatment, obtained by drying;

[0076] Among them, the fiber surface treatment agent, based on its total weight as 100%, includes: 8.5% of hydrophilic diamino silicone oil, 0.38% of vinyl triethoxysilane, 0.25% of Span60, 0.41% of Tween80, perfluorooctyl 0.07% polyoxyethylene ether non-ionic fluorocarbon surfactant, 0.34% ethylene glycol, 0.38% carboxymethyl starch and the balance of deionized water.

[0077] The fiber surface treatment agent is prepared by the following method:

[0078] Add hydrophilic diamino silicone oil, vinyl triethoxysilane, Span60, Tween80, perfluorooctyl polyoxyethylene ether non-ionic fluorocarbon surfactant, ethylene glycol and carboxymethyl in deionized water in proportion Starch, after mixing for 3 hours at 45°C under normal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com