Preparation method of high-flame-retardancy lithium ion battery

A lithium-ion battery, high flame retardant technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor performance of lithium batteries such as cycling, increase the polarization effect of lithium batteries, and exacerbate lithium precipitation in negative electrodes. , to avoid uncontrolled combustion or explosion, reduce lithium precipitation, and achieve the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a highly flame-retardant lithium-ion battery, comprising the following steps:

[0027] Step 1: Mix the positive electrode active material (NCM523) and the flame retardant (tributyl phosphate) evenly, the amount of the flame retardant is 5% of the mass of the positive electrode active material, and add conductive agent, PVDF, NMP, knead and stir to obtain The positive electrode slurry is coated on the aluminum foil at a temperature of 90-130°C to obtain the positive electrode sheet;

[0028] Step 2: Mix the negative electrode active material (artificial graphite), conductive agent, SBR, CMC, and water evenly to obtain the negative electrode slurry, and apply the negative electrode slurry on the copper foil at a temperature of 70-90°C to obtain the negative electrode sheet;

[0029] Step 3: Wind the positive pole piece, the negative pole piece, and the diaphragm into an electrode group, and then bake, put into the shell, inject electrolyte, age, and...

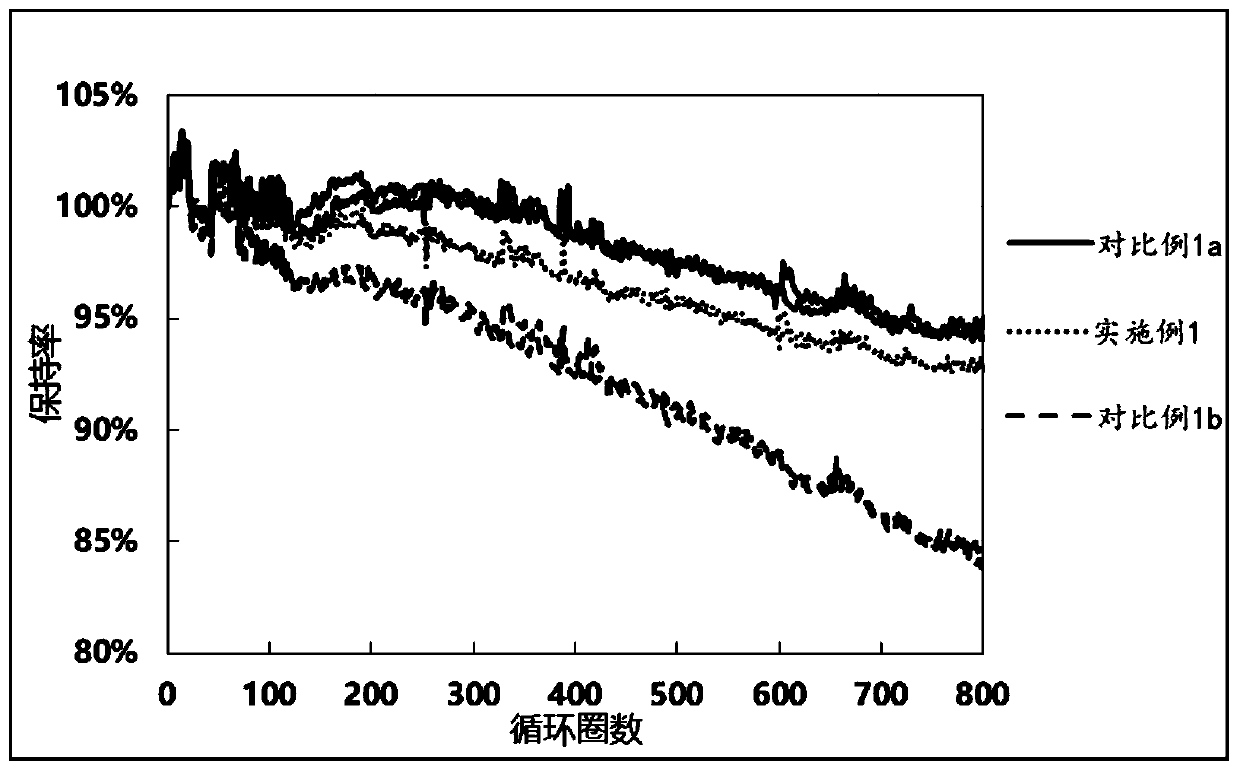

Embodiment 1

[0030] For Example 1, design: Comparative Example 1a—the difference with Example 1 is that no flame retardant is added; Comparative Example 1b—the difference with Example 1 is that no flame retardant is added in the positive electrode slurry, and the 5% of the flame retardant by mass of the positive electrode active material is added to the electrolyte.

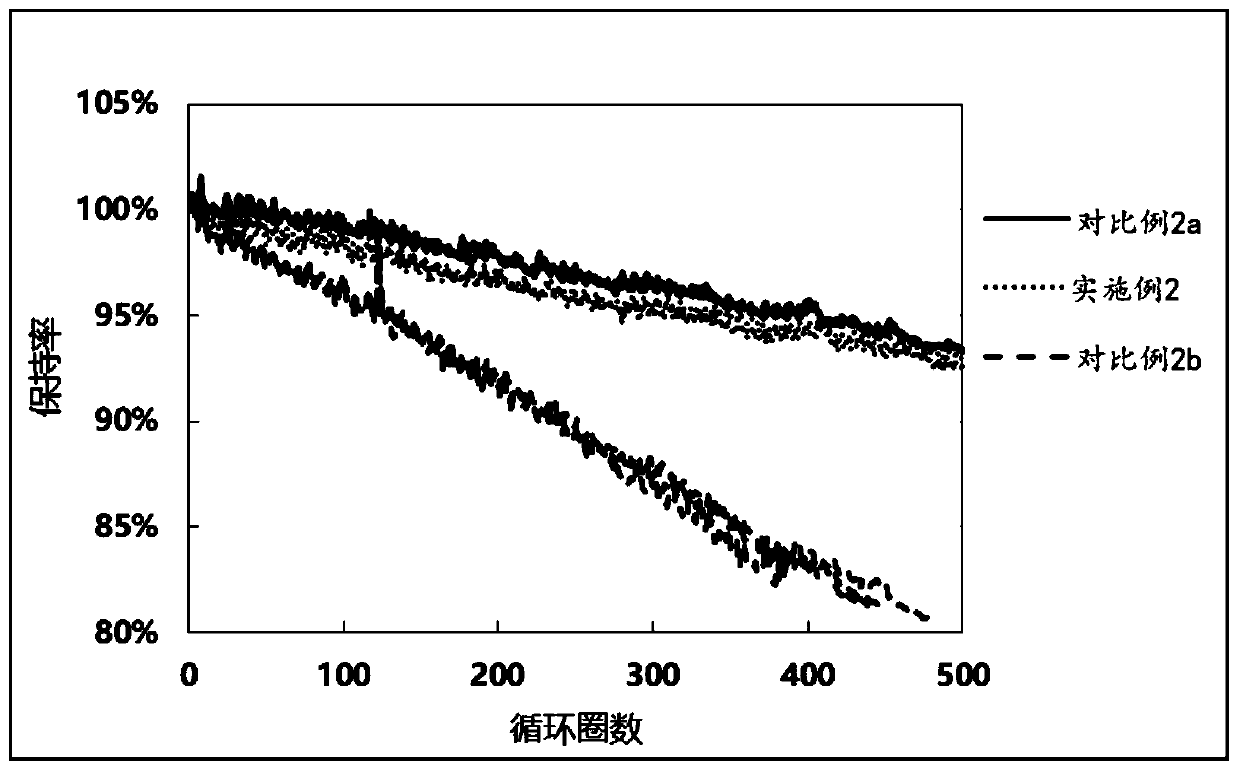

Embodiment 2

[0032] A method for preparing a highly flame-retardant lithium-ion battery, comprising the following steps:

[0033] Step 1: Mix the positive active material (NCM523 and NCM811 in a mass ratio of 1:1) and the flame retardant (tributyl phosphate) evenly, the amount of the flame retardant is 7% of the mass of the positive active material, and add Conductive agent, PVDF, NMP, kneading and stirring to obtain the positive electrode slurry, and coating the positive electrode slurry on the aluminum foil at a temperature of 90-130°C to obtain the positive electrode sheet;

[0034] Step 2: Mix the negative electrode active material (artificial graphite), conductive agent, SBR, CMC, and water evenly to obtain the negative electrode slurry, and apply the negative electrode slurry on the copper foil at a temperature of 70-90°C to obtain the negative electrode sheet;

[0035] Step 3: Wind the positive pole piece, the negative pole piece, and the diaphragm into an electrode group, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com