Super guanidine gum suspension and preparation method thereof

A technology of super guar gum and suspension, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as low flash point, large construction friction, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

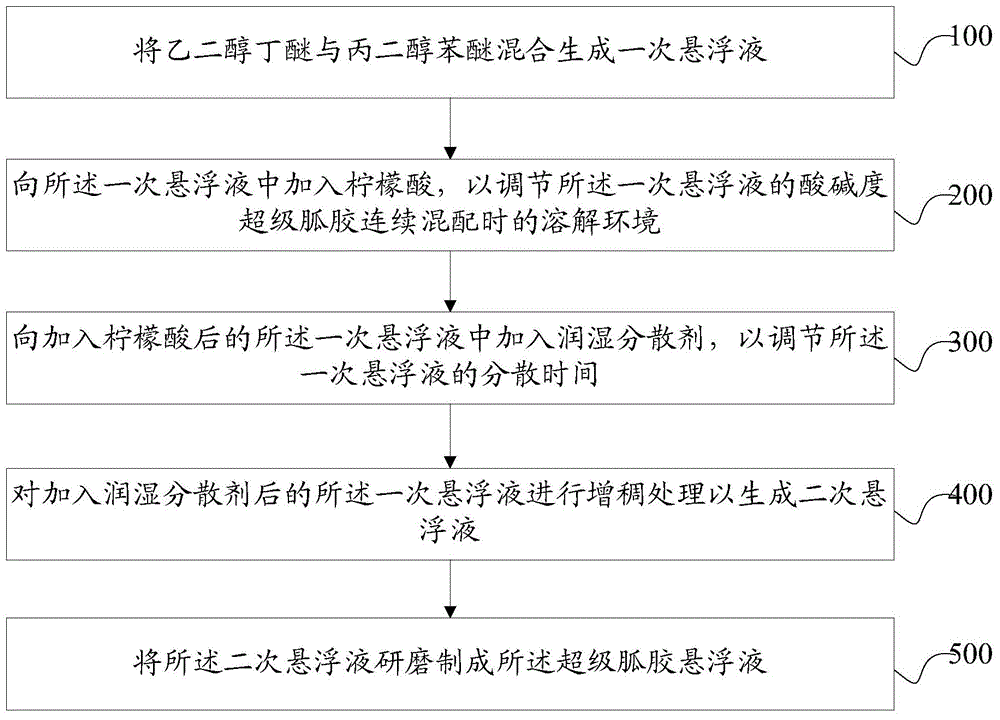

[0023] Specifically, see figure 1 , the preparation method of a kind of super guar gum suspension that the embodiment of the present invention provides comprises the steps:

[0024] Step 100: mixing ethylene glycol butyl ether and propylene glycol phenyl ether to generate a primary suspension;

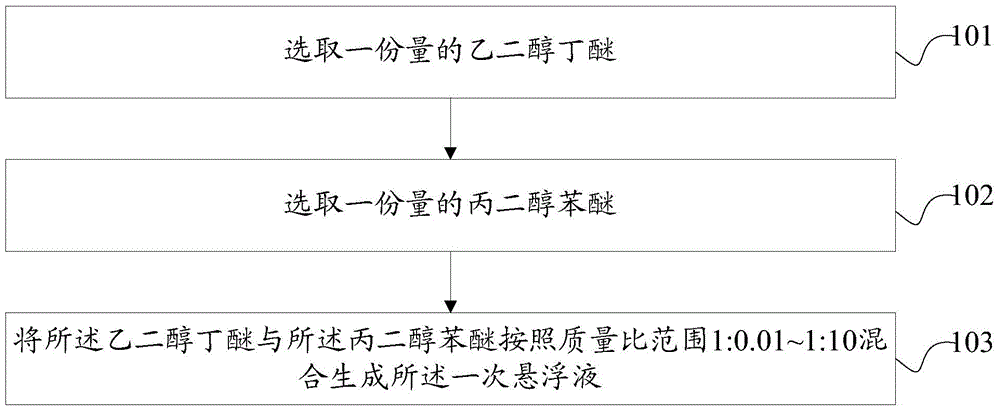

[0025] Wherein, this step 100 is used to generate primary suspension as the basic step of preparing super guar gum suspension, to suspend super guar gum, in this step 100, please refer to figure 2 , can specifically include: step 101, select a portion of ethylene glycol butyl ether; step 102, select a portion of propylene glycol phenyl ether; 1:0.01~1:10 mixing to generate the primary suspension. In this step 100, a primary suspension is generated by mixing ethylene glycol butyl ether and propylene glycol phenyl ether in a mass ratio range of 1:0.01 to 1:10, while ensuring that the primary suspension can suspend the super guar gum, so that through the present invention Example Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com