Mud-resistant polycarboxylate superplasticizer as well as preparation method and application thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete, can solve the problems of affecting application, adsorption of polycarboxylate water reducing agent, etc., and achieve the effects of improving cost performance, excellent water reducing performance, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

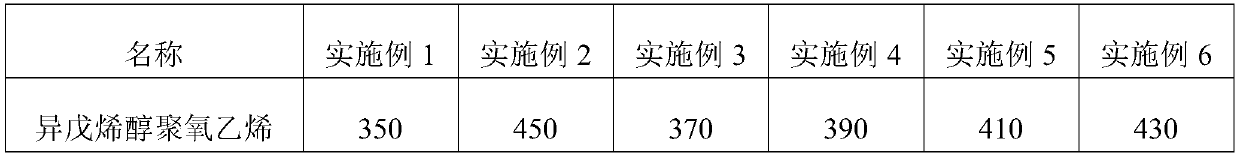

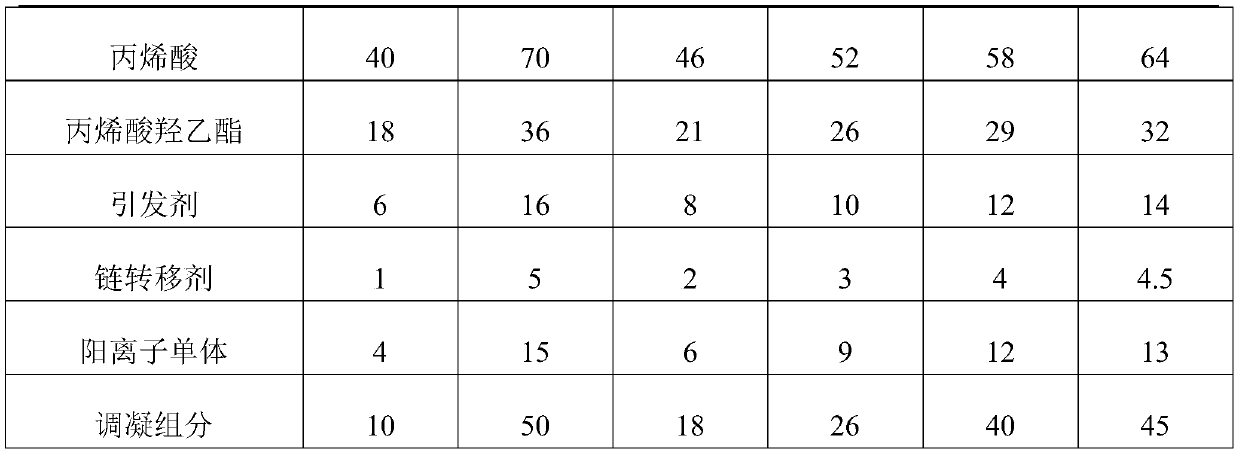

[0031] A mud-resistant polycarboxylate superplasticizer, consisting of the following components by weight:

[0032] 350 parts of isopentenol polyoxyethylene ether, 40 parts of acrylic acid, 18 parts of hydroxyethyl acrylate, 6 parts of ammonium persulfate, 1 part of thioglycolic acid, 4 parts of acrylamide, 10 parts of sodium tripolyphosphate,

[0033] Its preparation method comprises the following steps:

[0034] S1, material preparation: according to the above formula, weigh each component for subsequent use;

[0035] S2. Prepare materials A and B: dissolve thioglycolic acid in 150 parts of water to obtain material A, dissolve acrylic acid and hydroxyethyl acrylate in 6.3 parts of water to obtain material B, and set aside;

[0036] S3. Dissolving: adding prenol polyoxyethylene ether, ammonium persulfate, and acrylamide into water in sequence, heating to 60° C. to dissolve, and obtaining a mixed material;

[0037] S4, dropwise adding material A and material B: add material ...

Embodiment 2

[0041] A mud-resistant polycarboxylate superplasticizer, consisting of the following components by weight:

[0042] 450 parts of isopentenol polyoxyethylene ether, 70 parts of acrylic acid, 36 parts of hydroxyethyl acrylate, 16 parts of hydroquinone, 5 parts of thioglycolic acid, 15 parts of cetyltrimethylammonium bromide, 50 parts of citric acid share,

[0043] Its preparation method comprises the following steps:

[0044] S1, material preparation: according to the above formula, weigh each component for subsequent use;

[0045] S2. Prepare materials A and B: dissolve thioglycolic acid in 750 parts of water to obtain material A, dissolve acrylic acid and hydroxyethyl acrylate in 12.6 parts of water to obtain material B, and set aside;

[0046] S3. Dissolving: add prenol polyoxyethylene ether, hydroquinone, and cetyltrimethylammonium bromide into water in sequence, and heat to 70° C. to dissolve to obtain a mixed material;

[0047] S4, dropwise adding material A and materia...

Embodiment 3

[0051] A mud-resistant polycarboxylate superplasticizer, consisting of the following components by weight:

[0052] 370 parts of isopentenol polyoxyethylene ether, 46 parts of acrylic acid, 21 parts of hydroxyethyl acrylate, 5 parts of ammonium persulfate, 3 parts of hydroquinone, 2 parts of thioglycolic acid, 4 parts of acrylamide, cetyl tris 2 parts of methyl ammonium bromide, 9 parts of sodium tripolyphosphate, 9 parts of citric acid,

[0053] Its preparation method comprises the following steps:

[0054] S1, material preparation: according to the above formula, weigh each component for subsequent use;

[0055] S2. Prepare materials A and B: dissolve thioglycolic acid in 300 parts of water to obtain material A, dissolve acrylic acid and hydroxyethyl acrylate in 7.35 parts of water to obtain material B, and set aside;

[0056] S3. Dissolving: add prenol polyoxyethylene ether, ammonium persulfate, acrylamide, cetyltrimethylammonium bromide, and hydroquinone into water in sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com